What's new on the User Manual??? I see that it was updated/changed yesterday.

|

|

|

What's new on the User Manual??? I see that it was updated/changed yesterday.

This project is awesome! Was thinking I might have to make my own, then found this. Thanks everybody who has contributed!

I'm currently printing out a set of parts, and If things function well, might print out a mongo sized one next.

I do have a question I didn't find an answer for while browsing through the thread, though I'll admit to not reading all 300+ pages.

I mainly want to use this help load plinking/practice 9mm rounds in a lee progressive (bullet tip facing up). Need to order a ton of hard cast bullets, and am wondering how the different types may feed. Looking at 115grain round nose, or 125 grain conical. The larger conical rounds are a fraction more expensive, but I care more about reliability in loading.

Any known problems with either of the two listed types? Should I be looking at a completely different option?

If nobody knows about relative reliability of 9mm bullets, guess I can just start a bit slower and order smaller amounts of each for testing.

Thanks!

I used to use a Lee Pro 1000 with their bullet feeder and the collator/drop tubes. 124 round nose coated bullets (Bayou Bullets) fed well. I had issues with Berry’s copper plated 124 round nose slipping through the fingers on occasion. No experience with other profiles/weights.

Lee's bullet feeder isn't too reliable.....the 3d printed ones are way better.....

The only bullets that have given people trouble in TylerR's bullet feeder are the short square ones that don't have a heavier end. TylerR will have to tell you how they fared with experimentation.....I never use such bullets.....so zero experience here.

Excellent, thanks for the answers everybody! Sounds like I'll be fine with either choice as far as the collator goes. Thought the Lee bullet feeder looked finicky, but figured I could tweak it or print a different arm for it.

GWS, got a link to a 3d printed feeder that works well? I still haven't bought the Lee version yet, so I suppose that's good. Can try out something printed first.

This thread, came into being as a help center for the benefit of those who have been brave enough to buy 3D printers, who have a desire to learn how to print their own reloading equipment. TylerR was the one who developed it into a source of wonderful print files you can print at home to build this stuff.....and it all works well.

The print files are available if you download, the "downloads" link at the bottom of each of TylerR's posts (as in the post just above yours). This reservoir of 3D printing magic is not for sale, but created for private personal, not commercial use. People here can also help those who have trouble with their printers as well. Welcome to this part of the hobby! I only joined the 3D printer group here two years ago....turned into the funnest, most useful hobby within a hobby, that I do.

Ah, I overlooked the die section in the downloads, as I thought it was just for adapting to other press systems. Was looking for a bullet feeder that functioned like the Lee, that crimped in the same station.

I'll have to evaluate if the printed version will work for me or not. Should have probably waited for the 6 stage lee presses to come out. Would have liked to be able to squeeze in a powder checker. Maybe I'll try and figure out something automated with a scale for a finished round quality control check.

Got most of the collator parts printed though, and it sorts 9mm brass perfectly when spinning by hand. Hope to have a motor figured out soon.

I have a question regarding the 300mm feeder. I know it uses the "standard" size slide plates. I assumed, apparently incorrectly, that it also takes the standard ramp. Does the Mongo ramp fit or is there a 300 mm ramp lurking somewhere that I can't find?

While typing this it occurred to me I may not even need the ramp since I plan to use the 300 I am making as a case feeder only. I guess I'd still like to know which ramp should be used since I don't want it to look incomplete...

Sent from my SM-N981U using Tapatalk

Probably ought to be renamed, "Mongo_300 ramp".

I don't know what slicer program you're using, but the majority of them will let you import multiple .stl files. This will let you move them around inside the program, and you can see if/how parts fit together.

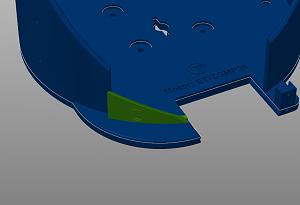

Most programs will also let you move parts up away from the bed, or sink them below it. That's what I did here with Prusa Slicer. Sunk the 300 size main body below the bed height, and then lined up the mongo ramp to see if it fits. Seems to fit perfectly to my eye.

Forgive me if this has been covered before, but I didn't find mention from my thread searches.

When I use this to feed .224 bullets into the bullet feed dies to load on my Dillon, I am having a problem with bullets getting flipped over by the collator, regardless of the initial orientation of the bullet in the collator slot. So when the bullet is correctly base down, it gets flipped to nose down, and vice versa.

I am using 55gr Hornady FMJ boat tail rounds. For the collator, I am using the Rifle_Bullet_Collator_Plate_Small_#2 (about 1 year old version though, not the newest which appears to have different depressions at the mouth of the bullet slots). I am also using the Bullet_Nose_Up_Slide_Plate_#2.

This bullet feeder worked flawlessly when using it for 9mm (different collator and slide plates of course) for what it's worth.

Is it possible the boat tail of the bullets I'm loading are getting caught on the slide plate ridge and getting flipped because of that?

Feeding 308 boattail with the #11 flip plate. I found that putting a screw in the hole on the back of the plate allowed adjusting the ridge to the point where the flat side would ride along the top like it should, while the point would fall down for rotation. I don't have any 223 bullets here or I'd test it out for you, but I bet something like that will help.

I also found that adjusting speed and the tilt of the body makes more difference than I initially anticipated.

I had the most trouble with nearly cylindrical bullets. The pointy rifle bullets were pretty easy compared to that. It seems like you have to tune it in for the particular bullets that you have. It's faster the more you do it.

Thanks- your advice helped! I played with how deeply the slide plate sits into the feeder bowl to adjust where the ridge of the slide engages with the bullets. I found that if I align the ridge with the outer edge of the collator plate, it prevents the tapered boattail of my base-down bullets from tilting the bullet (which starts the flipping process). Also tweaked the angle of the bowl a little.

So far so good!

Yup......see how easy this is to learn and tweak? You can fix a lot of problems with collator angle adjustment, and a change in width of the shelf/ridge on the slide plate.......and neither of you had to post a 1000 times like me to figure it out.

Probably harder for me to learn was how to to use my 3d printer well......and most of those problems went away with TylerR's printer bed recommendation! Polypropylene....no more masking tape, or spray on sticky stuff. Just a 10 second wipe with 99% rubbing alcohol before every new print.

Last edited by GWS; 11-22-2022 at 10:51 AM.

Hi - I am planning to print the main body wall extender in the orientation shown in the manual. Even if I set supports to 70 degrees there is a bit showing as needing supports. Looking for confirmation this prints okay without supports before jumping in to a 9.5 hour print. I am using an Ender 5 with Overture PLA Plus. Thanks

r4ndy, I've personally never printed one, so TylerR this is a question I can't help ease the burden on you!

Last edited by GWS; 11-22-2022 at 02:25 PM.

Hi guys,

@TyLeRr and @GWS and everyone who contributed, thanks for an awesome and exciting project to form part of.

2 Questions I have however:

1. Am I correct in thinking that PeTG will be a good material choice for this project, granted one has your print profile dialed in for PeTG?

2. Would a motor like this suffice, and is there any existing file that caters for mounting it? https://www.robotics.org.za/GB37-008

Thanks in advance.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |