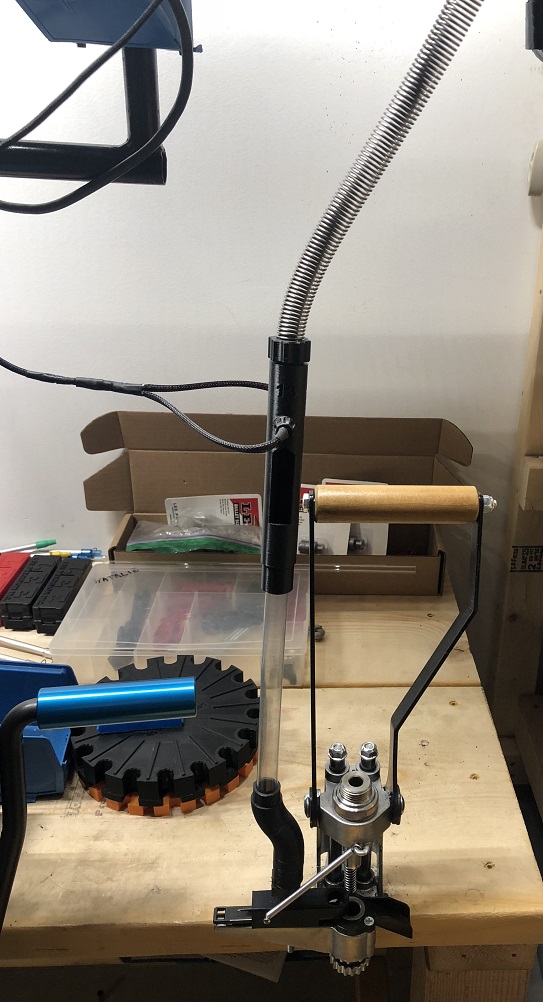

There aren't any blobs or strings on any of the parts... I am thinking that the size of the spring and adapters are allowing the bullets to get cockeyed and blocking up the works. It is the flat base of the bullets that's causing the problem.. if the went in nose down they don't get hung up. Have to wait a month for the next size smaller spring... and cost me an extra $12... I may see if I can print something up that will act like a funnel of sorts for the joints of the adapter connectors in the mean time.

|

|

|

Reply With Quote

Reply With Quote