|

|

|

Interesting... Yes I am using Cura.... I've read it can be done in prusa with "Modifier" box or cylinder, then change it to 0% infill in the modifier.

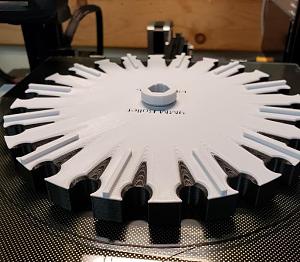

Printing another 9mm plate, and I was about to run out of filament..... so I cut off the black flush, and with a little panicking and forcing new filament in... This was the end result.... I kinda like how it came out!

Depending the printer and most can. You could of just paused the print. Then replaced the filament. Looks cool though.

Sent from my SM-N970U using Tapatalk

"Speak softly and carry a big stick; you will go far."

~Theodore Roosevelt~

Good to know you can do that......I was wondering what you do with all the "short" spools of filament.....Thanks for the education....

https://www.google.com/amp/s/amp.rig...ament-together

Fuse them together.

Sent from my SM-N970U using Tapatalk

Last edited by Rcmaveric; 01-28-2021 at 12:20 PM.

"Speak softly and carry a big stick; you will go far."

~Theodore Roosevelt~

My slip clutch is coming along nicely. Think you guys will like the final product.

Only issue is, and I hate to admit this, but it may require some support when printing the collator plate. Just no good way to add bevel to the bottom side of the "rotor disk".

Personally I think this is the best filament runout sensor you can get. If your filament jams the extruder will move to the side and wait for you to fix it, it you run out of filament the same will happen. I got tired of failed prints or the electricity going out in the middle of long prints so I use that sensor now. Just today (no clue what happened) my nozzle said it was warming up when I got home, I thought my print completed this morning when I was at work but it didn't. When I got home and saw the extruder parked on the size waiting I wondered what happened. The bed was still hot so the print didn't dislodge. My filament was stuck inside the nozzle, once I fixed that problem the print completed within 1-1/2 hrs. That was a 14 hour print.

https://www.google.com/aclk?sa=L&ai=...gQIBxBB&adurl=

Tyler, is that the pro or plus? I have been seriously considering getting an ender 5 but the only think that stops me is I already have 4 printers. Plus, if I get another printer I have a bad habit of tearing everything apart then replacing the system board, extruder, pretty much everything on the printer with better parts. And this is even before I use it for the first time.

Couple of different ways to do that. You can buy multicolor filament. You can splice the colors you want together your self with the link I posted earlier. Or use the manual pause and then swap out. There is a way to program the slicer to pause at various heights for color swaps. You program it the same way you do a temp tower.

Sent from my SM-N970U using Tapatalk

"Speak softly and carry a big stick; you will go far."

~Theodore Roosevelt~

Hey, I have a question. I searched through the many pages here and didn't see it asked yet. I built the AmmoMike bulletfeeder using the 370 motor. So far, so good. I am planning to print the larger case feeder and was thinking of using the larger version of the 370 I found. It has about double the torque. One thing I see now (and in the documentation) is the motor orientation is such that it will block one set of mounting holes. I see there are three choices (90, 180 and 270 degrees).

My question is why only orient the motor over the holes. Has anyone tried orienting the motor at 135 or 225 degrees? I did a (poor) tinkercad example of what I'm thinking. If the motor was oriented this way, it appears it should't interfere with the various mounting options. At least the holes are all exposed. This would be the same principle for the larger case feeder. Mainly, it would allow some of us to use the cheaper motor like THIS. The linked motor seems to have similar torque specs to the recommended one (40kg/cm) at half the cost.

Forgive my poor tinkercad attempt at illustrating my suggestion. It's not properly scaled, but you should get the idea.

Probably the perfectionist in us likes things straight.

With Tinker CAD it's pretty easy to fill in the holes with a block and create your own mount holes.

TinkerCAD has some pretty powerfull abilities that are hidden. Once you learn them it makes doing things like mount holes quick and easy.

I keep trying to learn FreeCAD. But those programs aren't easy or intuitive. Tinkercad is easy and I can do some pretty nifty functional pieces and designs.

Sent from my SM-N970U using Tapatalk

"Speak softly and carry a big stick; you will go far."

~Theodore Roosevelt~

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |