|

|

|

I already 3D print, but unlike the person who posed the question, I am a tinkerer. I like making things work right. Some don't.

I suppose there's an argument to be made that if you're reloading you've already shown that you're willing to Build-Check-Test-Fix-Repeat until you get where you need to be, but that wasn't my takeaway from his query. YMMV.

I just got through helping my brother set up a Mr. Bullet Feeder for his D. 650. If you think it's a plug-in tool with no tweaking, trial and error, or effort you will be disappointed. I think that goes for any tool you use for progressive presses, and progressive presses themselves.....including the Dillon 1050.

If you don't mind spending that much money, go for it......but don't expect it to be a can opener in simplicity, even preset up for one caliber. Pay attention to details for all of the above....or you have bumps.

The home-build 3D printed stuff is just as good, but the above applies to them too.

It's just that a 3D printer is money spent on a much more versatile tool, that when bought and learned can produce a lot of tools, not just bullet feeders, and other useful things that make you smile, and once I bought and learned, I made 2 bullet feeders and a case feeder, and several other reloading tools, plus stuff for my wife, for my car, and even a wearable Clone Wars helmet for one grandson, a T-Rex skull for another.....For the money I'd have spend on one Mr. Bullet Feeder and caliber conversion kits. Wasn't that hard to learn either....and I just celebrated in July the 1st anniversary of the purchase. The plastic media is cheap too! All that said, keep in mind, 3-D printer isn't for the impatient ..... but for me it's a fun way to keep this 70 plus soon to retire gent, busy.

Thanks for the replies gentlemen.

I am a little more technical than a caveman...lol. Engineer with a half dozen patents....but when I see guys who know what they are doing taking over 200 pages to date...well it seems a bit more involved.

What machine would you folks recommend and what add ons are needed.

I am OK with it taking 24 hours to print stuff. I am not OK with taking three attempts to print out a workable piece, or it being so fragile it needs to be replaced every 30k rounds.

Don Verna

I have owned and used all the Dillon machines and find them easy to use with minimal tweaking. Nothing like Lee progressives which I would class as marginal or worse.

Without meaning to be offensive, why would your brother invest in a Mr Bulletfeeder when you can produce a cheaper unit that is just as good? Your post has raised a red flag wrt to homemade vs a commercial product.

Don Verna

There is absolutely no question you would pick up 3d printing easily. As far as which printer to get, you are going to get lots of different answers, but I really enjoy my Ender 5 and 5plus. The only add ons I have for both is a poly build plate.

Edited to add, there is nothing fragile about a 3d printed collator. It is designed to last. If anything is going to go after 30k rounds it would be the motor or electronics, but that is true for a factory feeder as well.

Last edited by TylerR; 08-02-2021 at 10:42 PM.

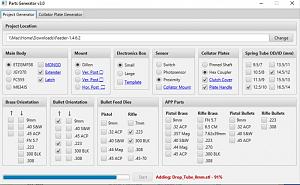

I downloaded the latest file from the Git and the Project Generator is hanging up on Adding: Drop_Tube_10mm.stl

Another side note, I havenít been able

to get the project generator to work in MacOS. Running the latest Java.

Sent from my iPhone using Tapatalk

Not offended.....smiling a little.....understanding your concern.

I own, with another brother, a design/build contruction company. I'm the design/finish side of it..... except that I spent my fair share the last 50 years getting projects out of the ground too after making 10 to 20 pages of Autocad Drawings for each of them.... My other brother chose medicine for a career (smarter for sure)....becoming an ER Doc and also now owns an Urgent Care business on the side. He bought a Dillon 650 3 years ago, and just last month asked me to help him set it up and teach him how to reload. He bought the bullet feeder because it's in the Dillon catalog and he knows nothing about 3d printers. As a novice, he naturally assumed the M.B.F. was the safer easier choice....and I don't fault that. He's used to putting people back together not tweaking machines or tools, but he'll get there.....

I will add that he wasn't real keen with the price of changing calibers.....so I suggested we could print a plate for his rifle on my printer, for about $8 worth of plastic and collate more than his 9mm.....he jumped on that possibility. (he will probably still buy a feed die) Me and 3D printed feed dies haven't made an acquaintance yet.....but I plan to check them out too. I use the new RCBS rifle feed dies and old Hornady pistol feed dies bought before M.B.F. started selling them separate.

I don't use Lee or Dillon.....except that I bought a Lee APP case processor, and Love it. Otherwise my presses are all green....Rock Chucker, Summit, Pro 2000, and Pro Chucker 7.....and while my progressives are less sage than Dillons, I like them for their fast caliber changes and the ability to use fewer powder measures. I think Dillons are fine presses.....just prefer what I have. After running his 650, I'm not seeing much difference excepting the powder measure. I do like having 7 stations, but still concede that RCBS has had less time to perfect it.... it works fine with minor tweaking....

The M.B.F. plates are strong and heavy....plastic but feel like metal. I didn't see a clutch system, but maybe it's in the motor? If not then that's why the plates are strong and heavy....to keep the motors from ripping them apart when there's a bind. (bullets are prone to that....don't care what design you have. With a clutch the plate stops, but the center keeps moving until you find the offending bind, then it continues. If no clutch you try to turn it off before something bad happens.

I print plates with like 18 percent in fill.....so that makes them light weight, but I never noticed any wearing. A few people have printed them solid. Makes them heavier for sure, but also prints in days not the eight hours mine print, and I find that unnecessary.

The printer I bought was a Creality CR-10 V2., because it had a reasonable price and a larger bed than most. There are even larger beds....TylerR added a new model with an even larger based Creality (thinking Ender 5+), and he designed his larger "Mondo" model of collator around it for to print larger rifle case feeders the size of Dillon's. My case feeder is the size of his original Bullet feeder base, and I find it works fine for anything up to .308. M.B.F. doesn't make case feeders, but then you probably have Dillon's case feeder already, since Dillon's 650 design is a PIA without one, requiring case feeding and press stroking with the same arm. Nothing wrong with Dillon's case feeder if you have one....just not as inexpensive as printed ones.

Not everyone wants to spend a lot of money on Feeders.....and more than a few like to build things themselves, and choosing to spend a $500 bill on a 3D Printer, means I'm not limited to just enjoying 1 bullet feeder with several caliber change kits for the money.

Last edited by GWS; 08-03-2021 at 06:15 PM.

The lock up problem appears to be caused by the selection of the 9mm Bullet Feed Dies. I figured out that I didn't need the APP parts, and re-ran the generator without the APP stuff selected and it still locks up. ETA: It apparently doesn't follow the 9mm Die selections as the culprit.

Here are two more screen shots of it locking up.

Last edited by CS223; 08-03-2021 at 11:05 AM.

Older links have been removed.

Mine won't complete if I select "Clutch Cover" but works fine with the rest (Note I have not tried any of the APP selections). I just grabbed those manually.

For a simple single caliber setup setting up a feeder is straightforward with the awesome instructions and design this crew has put together. Getting good prints is a bit of a time investment if new to 3d printing, but also not really difficult for someone with attention to detail. Also I like a glass bed but others use something different. Once you have the printer humming it should print consistently for all the parts. Also a rudimentary understanding of wiring and ideally soldering is needed for a nice clean build.

If willing to spend a few more bucks I would get the ender 5 pro or plus and an enclosure. There are a few parts to print for bed and wire strain relief for the printer. The enclosure takes the variable of room temp/drafts out of the printing equation. I would also get a raspberry pi, wifi plug and camera to monitor your prints and kill the machine if necessary during the longer prints if you arenít home.

All the pages are continued improvements and variations. I built a set for a friend with nose/up down bullets in four caliber and four brass down options and a set off app parts for four calibers - it took a while to print that many different options, but I had no fails on an Ender 5 pro.

I will say donít go cheap on the printer. I first built an AmmoMike collator with an Anet A8. The printer worked, but required more upgrades and tweaking then my old Lee pro and now it sits in the corner, I donít even want to give it to someone as it is such a hassle to keep running properly.

For what you are looking for I would suggest printing if you have any inkling you will use the printer once this project is complete.

Sent from my iPad using Tapatalk

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |