See folks? A beginner does just fine with a 3d printer......it's only a little scary at first, quickly becoming easy peasy. Looks great Huntinherrington! The hardest part is making the leap and buying one.

|

|

|

See folks? A beginner does just fine with a 3d printer......it's only a little scary at first, quickly becoming easy peasy. Looks great Huntinherrington! The hardest part is making the leap and buying one.

Last edited by Huntinherrington; 09-07-2022 at 08:48 PM.

it being a prusa helps a lot in this case. Ive had mk2s and the mk3+, even launch day enders (I have 4) and other printers, but the assembled prusas and their slicer (which has creality defaults too), really make it an easy experience for new printers.

I don't doubt that. But when I bought my Creality CR10v2, I was just as raw as him. The first print was some little thing, and I quickly learned I did NOT like bed leveling.....think it was Redleg Ed who told me about automatic bed leveling and steered me to TH3D. https://www.th3dstudio.com/product-c...-bed-leveling/ His expensive Prusa most likely already has one. The first day after installing that I printed This: (grandson's birthday present) TH3D autoleveler is the blue and black thing hanging on the right of the nozzle assembly.....no moving parts....just a specialized proximty sensor run by software provided. No probe to worry about breaking, by a errant unintentional nozzle lowering command.

And never looked back. Was there bad days.....yeah.....different brands of filament have different settings, and then you have lifting problems, babystepping problems.....it's called learning a new hobby. But the best thing I did was get TylerR's recommended bed, Polypropylene. No more lifting problems as long as I keep bed temp at 65 and nozzle temp at 215 for the PLA I like to use.

Last edited by GWS; 09-07-2022 at 11:38 PM.

I think when I got my mk2s, it was the only printer under $1000 that had mesh bed levelling. The kit was $599, but I will never do that again, the MK2s used threaded rods instead of aluminum extrusion, I think the first kit took 6 or 7 hours to assemble, because it's in every sense of the word a kit. I think 3 months in the wiring on the heat bed wore out and they express DHL sent a new one. Support for the first year is really reassuring for a beginner too.

the downside is that when you pick up a second printer like an ender 3, then you have to learn the nuances of bed levelling. The ender 3's were much easier to install hemeras though, love that hot end. Lots of cool stuff in the first years like the SKR boards coming out, that was a big deal at the time for the price.

At work we just got an intamsys Funmat to print PEEK, the chamber is hot enough that they give you welding gloves to take out the build plates!

Anyone used Overture PETG?

How did you like it?

I've had excellent results with Overture PETG on my MK3S+ running it at the default settings in the Prusa slicer for their Prusament PETG. I've only used Overture's Digital Blue and Space Gray.

I did purchase the kit and it took 8 hours to assemble, but in doing so, I hopefully learned enough to make maintenance/repair tasks easier.

Thanks you the feedback!

I’m ordering the black, digital blue and orange to try.

Is there a "fence" or rail I can add to the slide plate to keep the occasional bullet from falling over and jamming the drop hole?

I am running nose down with MP 358-125's, and they have a pretty wide flat nose.

I have settled on slideplate #6, after trying various configurations with #4 + #5. I get an occasional upwards bullet tipping over and jamming square in the drop hole.

My 124gr round nose FMJ ran great when I initially tested my unit.

Visit my projects at: http://cheese1566gunsandstuff.shutterfly.com/

Tyler's going to suggest you post a video......otherwise it's really hard to tell what you have going on. Assuming you are sizing boolits? Not something I ever do, but I think he does.

Will do. It's going to be dedicated to one of my Star sizers for 9mm.

I've tried three slide plates, with in/out-and various tilting of the body, and speed rotation combinations. Just doesn't like that profile and wide meplate.

I have an idea to make one from flat spring from an old windshield wiper blade. Pretty sure one here could whip up a cad drawing and print it.

Visit my projects at: http://cheese1566gunsandstuff.shutterfly.com/

have you tried installing the optional screw in the back of the slide plate to push out the plate further? sounds like you might be in between plate 6 and 5?

Visit my projects at: http://cheese1566gunsandstuff.shutterfly.com/

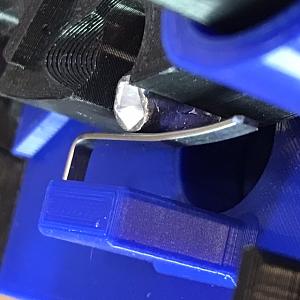

I added a piece of spring steel to act as a rail for the tipping bullets. Bent the flat steel to shape, drilled an undersized hole. Heated the steel with a lighter and slid into the hole and let it cool.

Tilting the body back to prevent tipping caused other issues like the bullets not want to slide downward.

I’m sure someone with mad design skills could whip up a functioning piece to print to slip over the slide plate nub where I mounted the spring.

Visit my projects at: http://cheese1566gunsandstuff.shutterfly.com/

I've used the Overture clear and once I figured out some of nuances related to trying to print something clear it worked pretty well.

I just spent days fighting witha roll of Sunlu PETG (black). Printing at recommended temps I had lots of strings and wisps and the surface looked rough. To get a nice looking print I had to drop the temp down to 205 (which is the same temp I use for PLA), but then fought with adhesion issues and nozzle clogging. I finally got the thing I was trying to print (cooling fan duct) to complete, but also bought a roll of Overture PETG in black to tryout. I almost wonder if this roll of Sunlu stuff was mis-labeled. Their PLA has worked well for me, which is why I tried their PETG.

Sent from my SM-N981U using Tapatalk

I had awful results with TecBears PETG lifting and stringing and switched to Overture PETG and it worked much better, still never got it dialed in and just went with Overture PLA+. Was making AR speedloaders and found the PLA+ worked fine in the summer heat and didnít warp sitting in a gun bag in the trunk or on the range in 90+ heat, so no reason to jack around with PETG when the PLA+ prints like a dream.

I jumped in head first and bought like 12 rolls of Overture PETG. Hopefully it works good!! I use their PLA+ Now with great results but wanted the extra heat withstanding of PETG.

Hey Guys, I wanted to see if you guys could help me out. Maybe it's too late or something but I am looking to connect a spring from my Dillon case feeder to the Lee APP and one from the case feeder to the case feed adapter on the 650. I see Tanders Case feed adapters but I wanted to see if there was something else that also works with the factory adapters that I already have.

Also, thanks to everyone who has put in work on this project. I haven't been reloading or on here for a while but this project has advanced exponentially since I started following it in 2019/2020.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |