Dear Team !

I have been playing with the APP_Base_Slide but face a challenge with too much friction when the slide is assembled.

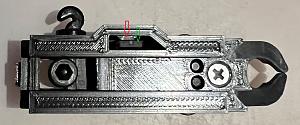

Just running the APP_Base_Slide solo is smooth. When assembling the keel shaped part (red arrow) seems to be pushing the green marked plastic too hard against the mount. Anyone else experiencing the same challenge ?

Med vänliga hälsningar/Best Regards

///Roger

|

|

|

Reply With Quote

Reply With Quote