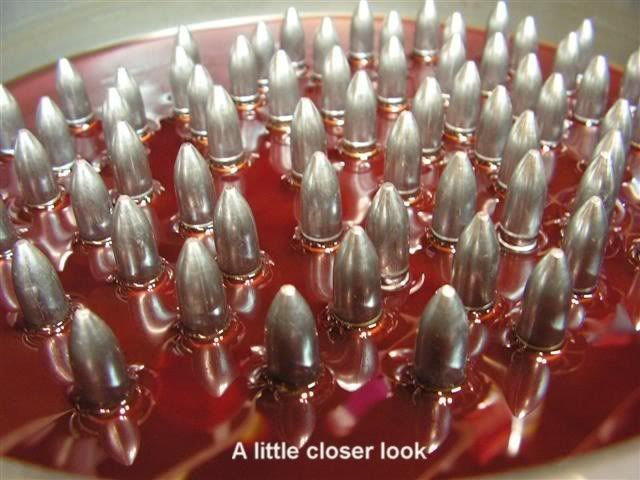

I have 3 different lubri-sizers. I have a friend that is beginning to take a real interest in cast bullets for his 03' Springfield.

Unfortunately he wasn't in the position to order a $114 Lyman lubri-sizer from Midway. So I introduced him to the " old way " of doing things.

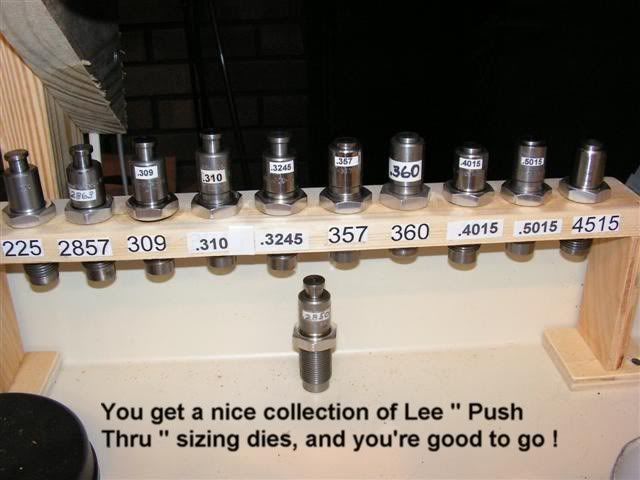

I use a lot of .30 cal. cast bullets that are sized .310 dia. Unfortunately Lee doesn't offer a .310 " Push Thru " sizing die for .30 cal. cast rifle bullets. So I ordered a .309 and opened it up to .310.

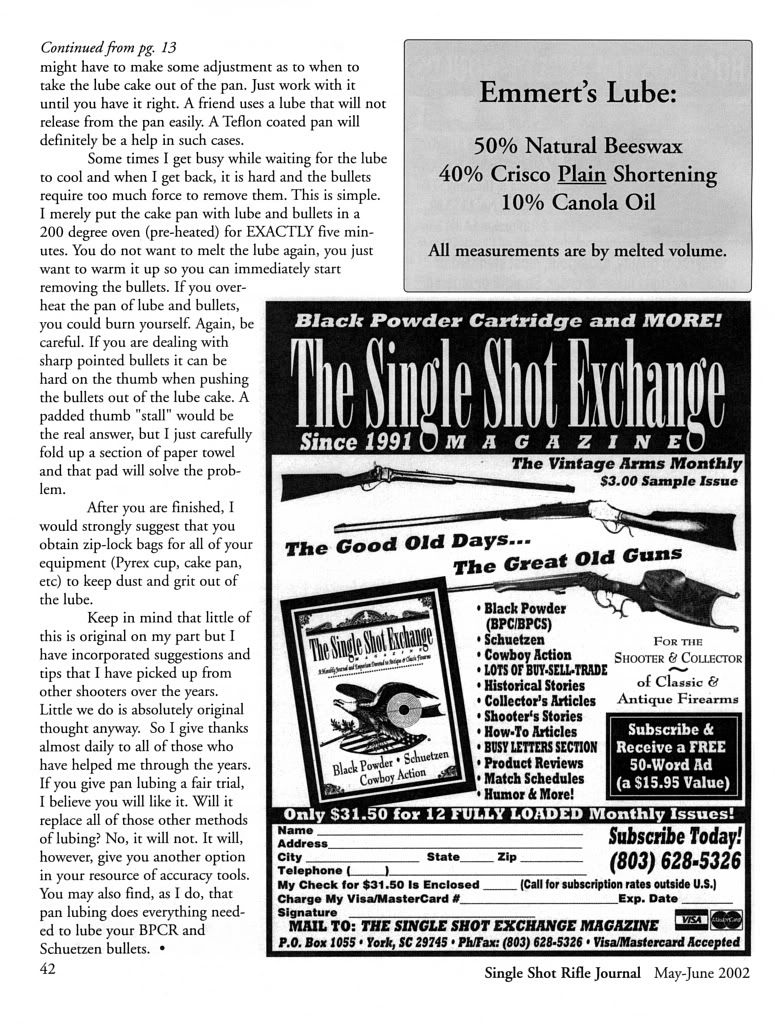

Bought a hot plate for $10, my wife was about to throw away a metal pan , so I grabbed that and said.." Hey, I need that ."

The Sizing die was $12.29 from Midway :

http://www.midwayusa.com/eproductpag...eitemid=501819

For someone on a limited budget , this is still a very effective way to size and lube .30 cal. cast rifle bullets ( and by using a " parent " case like a 35 Rem, for .35 cal. cast bullets, or a 444 Marlin Case for a .44 pistol bullet the system can easily be adapted to many other calibers other than .30 cal ) . Assuming you already have a .30 cal. mold, some bullet lube, and some gas checks, this equipment cost the sum total of $23.00.

Mis-alignment of the nose punch and the sizing die has ruined many hundreds of groups for me until I really began to understand what a concentric bullet was. In my opinion , the nose 1st system of bullet sizing is " THE WAY " to size bullets concentrically .

Photos below.....

You'll need a FIRED 30 / 30 empty cartridge case that is a snug fit over your .310 bullet. Take a 16 penny nail and turn the head of the nail to about .295 dia. I then cut a piece of wood dowel and make me a " push rod " to eject the lubed bullet from the solidified lube. Drill out the flash hole in the 30 / 30 cartridge case so that the 16 penny nail will slide freely through the hole.

The business end of the home made Kake cutter :

The $10 Elect. Hot Plate

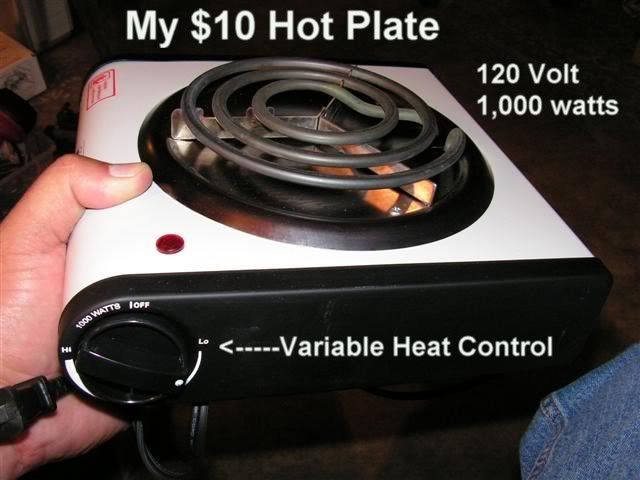

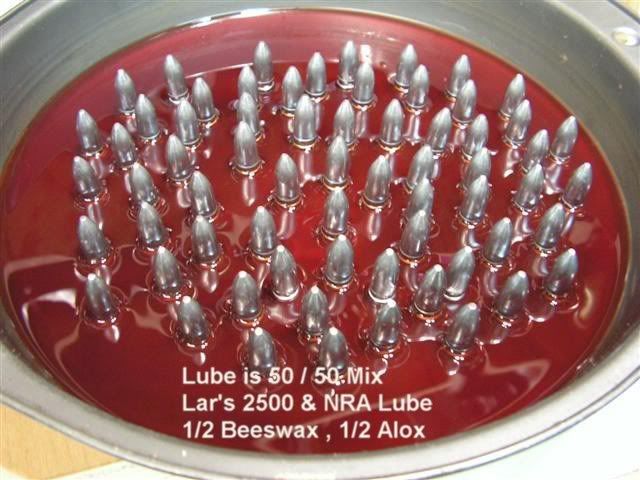

The lube is melted in the metal pan and the bullets that have already been sized to .310 are placed in the pan of liquid lube :

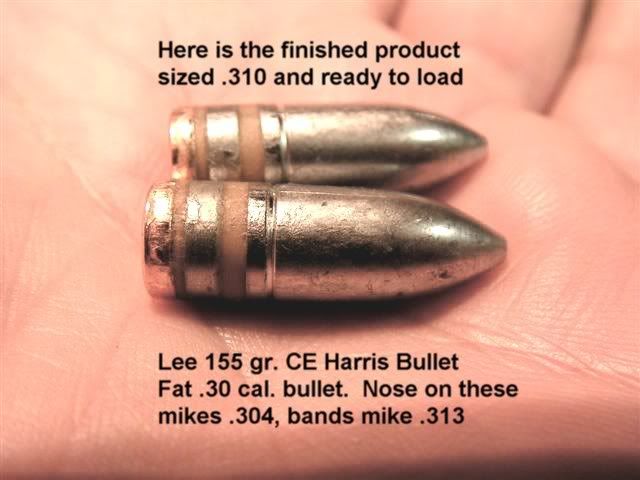

Here is the finished product ready to load and shoot :

Here is what the bullets look like when they are removed from the cooled , solidified bullet lube with the " Kake Cutter " :

Next question is , will they shoot ? ?

I have a Custom Hvy. Barrel , A & B, F-54 contour , stainless fluted , VZ 24 Mauser bench rifle chambered in .308 Win. that really likes the Lee 155 gr. , CE Harris bullet sized .310 , with 17.5 grs. of 2400 and a Fed 210 primer. The bullet is seated into the lands so that light engraving occurs upon chambering . This group was fired at 50 yards with the bullets that you see , 5 shots with a .22 rim fire case for size comparison purposes :

|

|

|

Reply With Quote

Reply With Quote