I have also not had good luck with PP. But am going to try again.

I am in the process of making pound casts of my chambers. To help figure what my target measurements will have to be. Have you done that?

|

|

|

I have also not had good luck with PP. But am going to try again.

I am in the process of making pound casts of my chambers. To help figure what my target measurements will have to be. Have you done that?

I have not yet done a chamber cast or pound cast of the chamber. This Rem700 is a new rifle bought a few months ago after the wife said "Why Don't you buy a new Rifle". I did pound the nose of a RCBS 165 Sil boolit into the muzzle. Measured the Lands to be .300 across from that test.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

For the test shoot on 6 December 2016:

Best 10 shot group to date today using the Paper Patched RCBS 165 Sil boolit. The Group was 3.137 MOA. Not where I want to be yet, but much better than before. Temps today at the range was 8 degrees Fahrenheit, which caused me to initially have some concern that Temps could potentially affect both my shooting and groups (Temp sensitive affects on powder burn rate). It seems to have worked out well, but the rifle and ammo were much warmer as they had been in the heated Jeep; not on the shoulder hiking in 8* weather.

__________________________________________________ _______________________

I changed the diameter of the boolit. First I sized the RCBS 165 Sil boolits to 0.308 in a Lee Sizing die, then used an NOE nose die to size the entire boolit to .305.

I then once again used Costco Parchment Paper to wrap the boolit (~ 0.002 thick), patch was soaked for 10 minutes in water (Paper curls when dropped in water – You need to straighten it out and place back in water prior to use), then rolled the Paper onto the boolit using a Cigarette Roller, about 20 turns of the roller.

I then unrolled about 2/3 diameter of paper, glued the tail with Pergamano brand Pergo Glue (Find it on Amazon), then hand rolled the tail onto the boolit using a pad (similar to RCBS Lube Pad). I pressed down and rolled each boolit three additional times the length of pad. Tucked the excess Paper Patch material onto the base of the boolit, stood each on the base to hold the tucked portion against the base while drying. After boolit dried 24 hours it was lubed with Lanolin (5 or 6 sprays of Lanolin liqufied in 97% alcohol - let alcohol air dry off - gives very light Lanolin application), then sized in a Lee 0.309 Sizer die. Paper on boolit where it was sized almost looks like a uniform white plastic after sizing.

Neck of .308 Winchester Brass was expanded with an RCBS 0.308 neck die – slight bell on mouth. Boolit placed into expanded neck ensuring no misalignment or damage to Patch; then case was placed into shell holder and the ram was slowly lowered to seat boolit to overall length of 2.665 inches. The die is set to close the expanded neck; BUT no crimp is on the brass after seating. The 2.665 length on the seated RCBS 165 Sil boolit makes the top edge of the Driving band/Nose area seat along the mouth of the brass.

Win760 Loads Paper Patched RCBS 308 Sil - 161205.pdf

(Full Load Data is attached above. Click the PDF to see data).

I have and order in with NOE for additional sizing dies inserts in 0.300, and 0.301. Will use these for additional testing in the future. May place and additional order for 0.303 and 0.304 dies given the better results todays provided. Anticipate my next test will try the Tracing Paper with the boolit sized to .0305 (Todays test with only a change in paper used).

Last edited by MUSTANG; 12-09-2016 at 12:31 AM.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Greetings, Mustang. I've been following your efforts and if I could offer a comment or two, I'd say our alloy would be fine for full power with a bare lubricated boolit, but probably too hard for the thin (and delicate) papers you've tried. I'd suggest trying a tougher paper for a boolit that hard. The paper I use most often is 100% cotton drafting vellum, usually .0025 thick, which adds .009 with two wraps. The math seems wrong, but that's how it works out in practice. It's tough enough when wet to stretch with much more force than bond papers can stand and I needn't worry about tearing them. An E-size sheet will cost you $2 or so at an art supply store and will make a couple hundred patches, but cut the strips from the narrow edge of the sheet for added stretchability and shrinkage when drying. Given the short ogive on that RCBS 165 Sil design supported by the patch, you won't need alloy anywhere near 22 BHN. Quenched wheel weights at the most. Air cooled should be fine. Very hard alloys and delicate papers don't go together well and the driving bands may be clipping through the paper on the lands. Another possibility is the alloy may be too hard for the pressures generated. Lee talks about this in the Lee loading manual, matching alloy hardness and chamber pressure.

You seem to favor a systematic approach. Keep whacking at it - you'll get there.

yeahbub:

Drafting vellum is an idea I am interested in adding to the test series. Is the drafting vellum you are using a 16 lb version? Amazon has several different offering in Vellum paper, the one I was looking at is Clearprint 10001410 Design Vellum Paper, 16 lb, White, 8-1/2 x 11 in 50 sheet pads. This is available from Amazon as listed in the link:

https://www.amazon.com/Clearprint-10001410-Design-Vellum-CHA10001410/dp/B000F7ARPQ/ref=sr_1_5?ie=UTF8&qid=1481296602&sr=8-5&keywords=vellum+clearprint

Before I retired a few years ago I could have gone over to the Engineering Department and picked up some Vellum (They had flat drawers full that were never used because of AutoCad design vs hand drawing now-a-days; with huge printers, but the paper for those was not vellum). Appreciate your thoughts on the 16 Lb vellum before I order.

Last edited by MUSTANG; 12-12-2016 at 10:52 PM.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Mustang

A couple of questions/comments:

1. After you size the 165gr RCBS Sil. CB, PP it, and resize it; have you ever removed the PP and miked the smaller diameter bore-riding nose and the larger diameter base? If so, what were the dimensions?

2. How did you determine the OAL of your PP round?

3. Final diameter of the PPCB, for the 308 Win, should be 0.308"D as determined by the NRA. Anything larger in diameter will cause the 308's chamber's forcing cone to tear the PP as the PPCB round is chambered. A torn PP will cause inaccuracy.

Hang in there. You're getting close.

Best regards,

CJR

Is that stuff still at the company you worked for and do you know someone there? Might be able to get it for a song if they have no use for it. When the company I work for went to 3D CAD, all the drafting stuff was shifted first to one corner and then to another. Beautiful stuff, treated like so much junk. Sad. The vellum I use is Clearprint 1000H 16lb Traditional 100% New Cotton Fiber - Solvent Free, Plain (no title blocks or borders, just blank paper). Personally, I don't much mess with 8.5x11's. Too much fiddling with short strips, but if it's all you can easily get, it'll certainly work. Drafting vellum is as close as you can get to what was once called "bank note" paper used for patching a century ago. I went big and bought a roll, 42" x 20 yards when I saw it on sale online, $38 IIRC. There's a lot of patches in a 42" strip. If you have access to an art supply place, you can buy a big sheet or two for less than $5 and see if it works for you. The best price I could find after a quick search is at http://www.jerrysartarama.com/clearprint-vellum-rolls, 18" x 5 yards for $8.59. It generally runs .0025 thick and is very consistent. I patch and size, so paper thickness is less of a consideration than for someone who depends on patching to a precise diameter.

I had another idea about those hard boolits you have. Have you considered patching them with .001-.0015 copper foil? It would stand up to the hard alloy, but I remember reading that approach had it's own peculiarities. Just an idea. . .

Last edited by yeahbub; 12-10-2016 at 11:57 AM.

For the test shoot on 12 December 2016:

This 10 shot group used Tracing Paper to Paper Patch the RCBS 165 Sil boolit. This Group at 6.306 MOA, was significantly larger than the one in Post #23 above, which had used Costco Parchment Paper. Previously on the 21 November 2016 testing, I had used the Academie Tracing Paper with poor results (the boolit in that Test had been sized to .302, this one to .305). Although today's test proved much better with the Tracing Paper compared to the 21 November effort, I am not encouraged with this paper choice.

I ordered a pad of Cotton Drafting Vellum from Amazon based on the comments from yeahbub (post #24 above). I am thinking the tracing paper is too weak to provide an effective paper jacket. Hopefully the paper Vellum will roll and seal to itself without the glue and extra effort I am expending with the Costco Parchment Paper. The ready availability, coupled with better (although not yet acceptable) results of the Costco Parchment Paper is why I've chased it so far.

Win760 Loads Paper Patched RCBS 308 Sil - 161212.pdf

(Full Load Data is attached above. Click the PDF to see data).

Last edited by MUSTANG; 12-12-2016 at 11:24 PM.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Mustang, how about some photos of those patched boolits? Are you using gas checks or leaving them off? I don't use them with PP and don't seem to suffer for it. Here's a post on the tecnique I use, http://castboolits.gunloads.com/show...t-the-paper-up. Curious how you do it. . . .

Last edited by yeahbub; 12-14-2016 at 02:01 AM.

No I am not using Gas Checks when Paper Patching boolits.

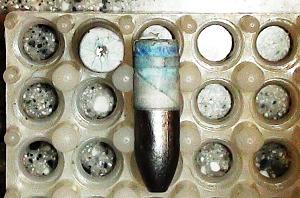

Above is a thumbnail pic of an RCBS 165 Sil (.308) sitting over the Paper Patch aligned as it will be to begin wrapping. The line on the patch was drawn with a Sharpie Permanent marker ~ 0.15 from the edge; this allows the paper "Tail" to be folded under the boolit edge to form a paper base after wrapping, forming a solid paper base smoothly flowing into the Paper Patch edge.

Paper Patching RCBS 165 Sil.pdf

The attached pdf provides a better look at the cut patch, dimensions used, and pics.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

For today's testing the paper was changed to Vellum Drafting Paper purchased from Amazon. The paper is .0029 thick (derived by measuring 50 sheets in the pad, and then dividing by 50). Boolit was sized to .305, patched & dried, than lubed with Teflon spray and sized in a .308 sizing die before loading. Group using Vellum Paper today at 6.360 MOA was about the same size as the Tracing paper group listed in post #28. Progress seems to be going sideways for now.

(Full Load Data is attached below. Click the PDF to see data).

Still waiting on 0.300 and 0.301 sizing dies I ordered, so reducing the boolit diameter in testing will have to wait. Next test I am going to look at reducing the diameter of from the .305 last used, to a diameter of .303 after the boolit is sized.

Last edited by MUSTANG; 12-16-2016 at 09:44 PM.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

For the Test on the 19th December I reduced the sizing dimension of the boolit to .303 compared to the previous test which used a .305 boolit sizing. Paper patch was Costco Parchment Paper once again at a dimension of ~ .002 thick. This one was a head-scratcher, as the first 4 rounds hit in the lower portion or near the edge of the 2” orange bull. I did not take the Spotting Scope so 1st couple rounds I saw nothing on the target through the scope, but was able to see the impacts at shot #4. Shot # 5 was on the backboard at 9 oclock, and the next 4 shots were dispersed on the backboard, with shots 9 and 10 missing the cardboard backboard entirely. With the exception of the boolit sizing diameter; load, PP’ing technique, and boolit were the same as in Post # 23 on 6 December.

After returning home I tried the technique recommended several times on various threads in the Smokeless Powder Paper Patching section to use a tight fitting dry patch pulled through the barrel from chamber to muzzle, feeling for tight sections. There was no detectable tight sections in the barrel (The technique is supposed to give a hint to whether Paper Patch is failing in the throat/forcing cone area of the barrel, or further down the barrel.). I used my regular cleaning technique for all of these tests, pulling a Brass Brush through the Barrel 20 times with a white rag positioned from the crown to a foot away from the barrel, then Hoppes #9 on a patch twice, then pull patches through until all fouling removed. In past cleanings where wide dispersions occurred, there would be the trace pieces of lead showing on the brass brush and white rag. This has not been the case in Tests conducted in November and December, indicating that there was no lead fouling – or it was so slight as to not be noted. In today’s cleaning after the test there was not observation of lead fouling and the powder fouling was light (similar to last few tests).

It is quite evident that the patch is not going down range with the boolits. During the test on 16 December (Post #32) there was a light wind coming straight at the bench, and immediately after each shot I would get a “Light Sprinkle” of very fine paper. Today, the wind was very light, from the North East. There was clean snow accumulation of about 18”deep in front of the bench, and a light peppering of paper sprinkles could be seen in the snow from a foot in front of the barrel out about 10 feet. Paper pieces were probably 1/16 to 1/32 inches in diameter; they were NOT shred/strips. This would be consistent with the Paper Sprinkles/glitter encountered on the shoot in Post #32.

For the next Test, I intend to go back to a 0.305 boolit sizing using the Costco Parchment Paper Patch; but I will be extending the length of the patch to where the nose of the RCBS 165 Sil boolit is ~ 0.300 as seen in the pic below. There is also the base of a boolit to the left showing how the skirt on all of my PP’d boolits have been folded over to cover the base for those interested.

Full Load Data is attached as a pdf.

Win760 Loads Paper Patched RCBS 308 Sil - 161219.pdf

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Testing on 21st December started with great hope. For this test group; the paper patch was lengthened from 2.455 x 0.59 to 2.455 x 0.785. This allowed the patch to cover from the Ogive of the boolit down to the base with a skirt rolled over to cover the base. Doing this brought the patch coverage into the area that many posts across this site have advocated as the "Proper" method for Paper Patch coverage on a boolit. The following pic shows an RCBS 165 Sil lubed & seated boolit above a Paper Patched boolit for this test. One can see the patch extending to the Ogive, and looking closely that the Paper Patch boolit is slightly deeper set (2.660 compared to 2.665) than the top round. Had to seat these boolit's slightly deeper to ensure chambering as the 2.665 depth would be a "Crush Fit" on the paper.

10 Rounds loaded for this test.

After shooting the 10 rounds at the range and reviewing the target I was fairly disappointed. The group appearance as you can see below was on target; but open.

At home I took the picture of the group and ran it through my ON TARGET software and was surprised when the group came up to be the 2nd best group size of this Test series on Paper Patching the RCBS 165 Sil Boolit. Lesson reinforced is that a deliberate approach to load development, consistency in approach and tools used, and effective records keeping is critical to quantifying results. If I had gone with my "Gut"; I would have developed a false bias.

Base on the limitations of two single 10 Round test groups; it looks as if the longer patch does not provide an accuracy advantage with my processes and materials. We'll hold that thought for future validation. Currently the testing on 6 December (Post # 23) has produced the best overall group; with today's test being the 2nd best 10 round group at 4.991 MOA; a 62% larger group.

Test data is attached as a PDF.

Win760 Loads Paper Patched RCBS 308 Sil - 161221.pdf

Next test group will focus on a 0.302 sized RCBS 165Sil Boolit and a Vellum Paper Patch (.0029 thick) applied to it and sized in a .308 sizing die.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

You might want to consider a couple of different metrics in your pursuit.

-Use a bullet intended for paper patch, ie. smooth sides and of proper diameter. There be a dozen or more reasons to do that, grease grooves are not your buddy.

-Given that, stop sizing after patching. Hell, stop sizing entirely. If the geometry is right, it is not required. Sizing is not the friend of precision. Bullet = bore-bore+.001". Patched bullet = groove-groove+.001. End of discussion.

-As previously suggested, a softer alloy. Pure lead typically works up to around 2,000 fps. Lyman #2 or rough equivalent will put you in the ballpark of 3,000 fps most days. We're talking BHN in the 6-15 range here, emphasis on the lower end of things. Probably you can run with something in the BHN 12 neighborhood. For paper patch to work properly the bullet MUST obturate. Your alloy will require something in the range of 35K PSI minimum to obturate.

-Paper choice is critical. Apologies to those who walk different paths, if your version works that's fine. Proper thickness and rag content are the righteous path. Wet the patches and roll 'em up. It shrinks after drying. .0025" onionskin (9# w/25% or greater rag content) will shrink to .002" after drying. It's all about the geometry. A clue as to proper quality of paper: when the patched bullet is dry, the patch should be formed and cling to the bullet w/o coming unraveled from light handling. Use a very light wipe of 50/50 beeswax/Vaseline for lube, applied with your fingers. Confetti puffs when you shoot are good.

-Folding the bottom of the patch over the bullet base is good. Do not be generous in how much you leave hanging over. Just a smidge (1/4 bullet diameter) is all that is required. After wrapping, set the bullet on its base to dry. If it won't stand on it's own you have too much clutter on the base, make it less so. This cannot be emphasized too strongly. Bullet base form consistency is critical to achieving high precision. If your load/case geometry allows, use a card wad under the bullet base.

-I assume your bullet is a bore rider design. Stop patching the nose, or minor diameter above the shank.

It ain' that tough, quit bangin' yer noggin on the bench.

.44 Mag, loaded per the above, Ruger 77/44 (stock) with a 3 moa red dot sight....load date and firing date on the target. Looks like 8, but it's a 10 shot group. As you might imagine, it does better with a conventional scope, but hey, it's a hunting gun, not a paper puncher. The bullets are pure lead, MV ~1,600 fps.

So simple a caveman can do it....

Last edited by Digital Dan; 12-28-2016 at 02:35 PM.

I have danced with the Devil. She had excellent attorneys.

28 December; Test group today was 3.948 MOA; better than achieved in post #34 (4.991 MOA) - but not as good as in post #23 (3.137 MOA). The paper patch today was Vellum Drafting Paper (.0029 thick) over an RCBS 165 Sil boolit sized to 0.302. Sized after Paper Patching in a Lee .308 Sizer die.

Load Data is attached as a PDF.

Win760 Loads Paper Patched RCBS 308 Sil - 161228.pdf

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Digital Dan provided some interesting comments/recommendations based on his personal experiences paper patching. It might be beneficial at this point in my thread to incorporate some thoughts and analysis of my efforts and direction based on his input in post #35 as well as other sources:

- Paper Patching using Smokeless Powder

- This thread is centered on attempting to achieve jacketed velocities using Paper Patched RCBS 165 Sil boolits. (171 Grains actual as cast Weight); WITH AN ACCEPTABLE ACCURACY LEVEL.

- Pressures for these Paper Patched RCBS 165 Sil boolits will be similar to those experienced in jacketed loads.

- A 175 Gr. jacketed bullet with 46 Gr of W760 yields ~ 40,300 CUP of pressure.

- Velocity of above ~ 2,484 FPS.

- At a future date I will Chronograph my RCBS 165 Paper Patch loads to get an actual velocity. Currently 24" of snow in front of Bench area at Range, may shovel some soon" But no one plows the road to the range, so even with 4 Wheel Drive Jeep; getting difficult to get up the road to the range now.

- Grease Grooved boolits and paper patching.

- This entire thread is dedicated to paper patching the RCBS 165 Sil boolit. Although many like Digital Dan, may experience better results with a smooth sided boolit; that’s outside of the scope of this thread.

- My inspiration for this thread is based on a desire to shoot Jacketed Velocities with the RCBS 165 Sil boolit, similar to the numerous threads on the Cast Boolit Forum where a variety of Paper Patched grease groove cast boolits have been used to achieve good accuracy.

- Ed Harris and the NRA articles on Smokeless Paper Patching back in the 1970’s are a foundation document. In their series they first tried to use straight sided (Turned Down) boolits with poor success. They then used .301 caliber cast boolits with light “lube Grooves” which resulted in better accuracy, thoughts were the light grease grooves provided a griping surface for the Paper Patch. This resulted in the Lyman 301618 and 301620 molds.

- This testing may eventually determine that a single residual grease grove on the RCBS 165 Sil boolit is insufficient to “Grip” the paper patch to achieve near MOA or Sub MOA; but that’s down stream. I’ll resort to using a rasp to lightly knurl the boolit bearing as a surface to grab the Paper Patch area if nothing else works downstream.

- Alloy hardness

- There have been a couple of recommendations to use a softer alloy. I may cast some more RCBS 165 Sil boolits in a few weeks, I can look at Air Cooling a portion as my 96-3-1 alloy will result in a much softer boolit when air cooled, rather than the water dropped previously used which yielded 22.7 BHN. Then we can compare performance difference in hardness.

- The NRA articles and numerous threads on this forum have focused on a harder boolit for greater velocities. The use of #2 alloy and linotype have been advocated in a variety of sources and posts for Paper Patched Boolits in the 2400 fps to 3200 fps applications. The Lyman Cast Bullet Handbook, Third Edition, lists a 15 BHN for #2 Alloy; and a 22 BHN for Linotype. My current 22.7 BHN Quenched boolit is at Linotype hardness.

- Paper Patch Sizing

- The NRA articles found that sizing the Paper Patched boolit in a .308 Sizer was critical, particularly when firing in a .308 Winchester/7.62 x 51 caliber due to the throat. The Lyman Cast Bullet Handbook, Third Edition, repeats this admonition.

- As time goes by; we should see with the Testing of Paper Patching this boolit if this is a valid admonition; or if there are “Windows” where not sizing the patched boolit in a .308 might work also.

Next Test string will use an RCBS 165 Boolit, 22.7 BHN, sized to .302 , and Patched with 9lb Onion Skin Paper. Thanks to ClodHopper for mailing me a few sheets of 9 lb Onion Skin Paper for testing.

Mustang

"In the beginning... the patriot is a scarce man, and brave and hated and scorned. When his cause succeeds, the timid join him, for then it costs nothing to be a patriot." - Mark Twain.

Stop doing that. Glue is the last thing you need in the mix.Tail glued with Pergamano brand Pergo Glue (Find it on Amazon).

You don't want the patch to grip anything. Lacking a clean release of all patch material when the bullet exits the bore you will not achieve your goal.This testing may eventually determine that a single residual grease grove on the RCBS 165 Sil boolit is insufficient to “Grip” the paper patch to achieve near MOA or Sub MOA;

If you're determined to make your particular bullet chamber and shoot you will need to size it. Last time a bullet was sized as much as you describe and produced MOA precision, Hell was frozen and the Devil was a regular kind of guy.The NRA articles found that sizing the Paper Patched boolit in a .308 Sizer was critical, particularly when firing in a .308 Winchester/7.62 x 51 caliber due to the throat. The Lyman Cast Bullet Handbook, Third Edition, repeats this admonition.

I respect your determination nonetheless and wish you all the luck in the world.

I have danced with the Devil. She had excellent attorneys.

I'm not a paper patch expert but I've had very good luck with barely hard boolits sized at or under the bore size and a double wrap of copy paper. Sized under bore did better. Softer boolits did fine. Spit wet and rolled tight on a board with the tail end curled into a twist without much of any tail. Stacked on another board drilled to hold 'em point down 'till dry. I sized the wrapped boolit slowly with just a very little bore butter. (Bore Butter = muzzle loading lube) Best of luck in your quest. This stuff is fun to do.

Not an expert here either, having just got started. I have had pretty decent results with the RCBS 165 Sil in the 30-06. Sized to .308, two wraps wet on my table with green bar printer paper, lubed with BAC and final size to .311. My next project will be for my Mosin Nagant, and I plan on using the 311407 boolit. I have the boolits sized and wrapped, just waiting on my Lee 314 push through sizer from Midway. It's been fun learning here and trying stuff "outside the box". Obviously it takes a lot of experimentation and patience, but I enjoy it. Mustang, keep up the good work, and thanks for your efforts and reports.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |