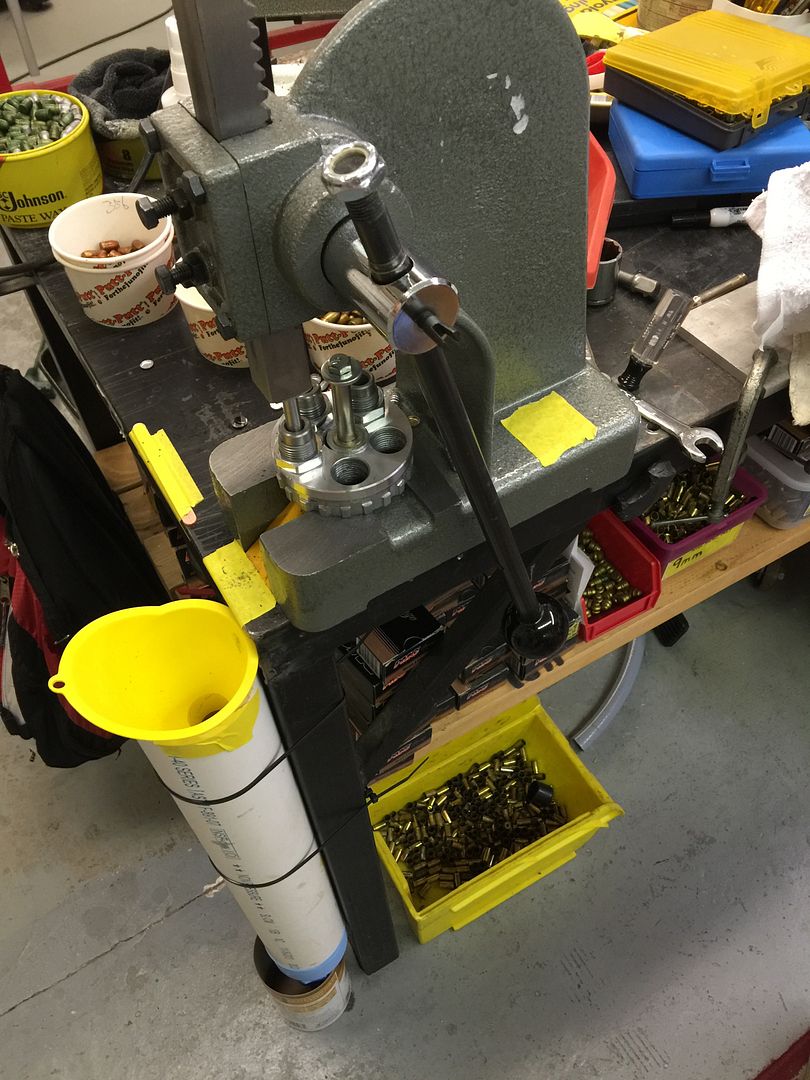

I found the idea here somewhere of mounting a press upside down so that you can just drop a bullet into the Lee sizing die instead of balancing it on the punch. What I didn't see was if anyone reversed the press' arm so that it works like a normal press - downward push instead of upwards.

So I tried it out.

I used the little Lee press, because its cheap. I made an arm from 1/4" steel (5/16" would be better in this press, but I had 1/4"). I had to grind a couple of divots in the bar so it would clear the ram at both ends of the stroke. I also had to mount it on some steel because 3/4" wood would jam the arms up. I still need to fit some spacers and make some kind of handle.

I'm sure someone else has already done this. Probably better. But I thought I'd share it. The press loses some of it's range but there is enough left for sizing bullets. If I was more clever I'm sure I could figure out what length to change the arms to get the best range of motion. I basically tried a couple of holes until it worked. I'm more of a hammer guy than a math guy.

|

|

|

Reply With Quote

Reply With Quote