Thank you very much 45 2.1 -

Well I've been planning all along on cleaning the bore (two wet wipes and one dry?) after each shot, and I will only be using black powder.

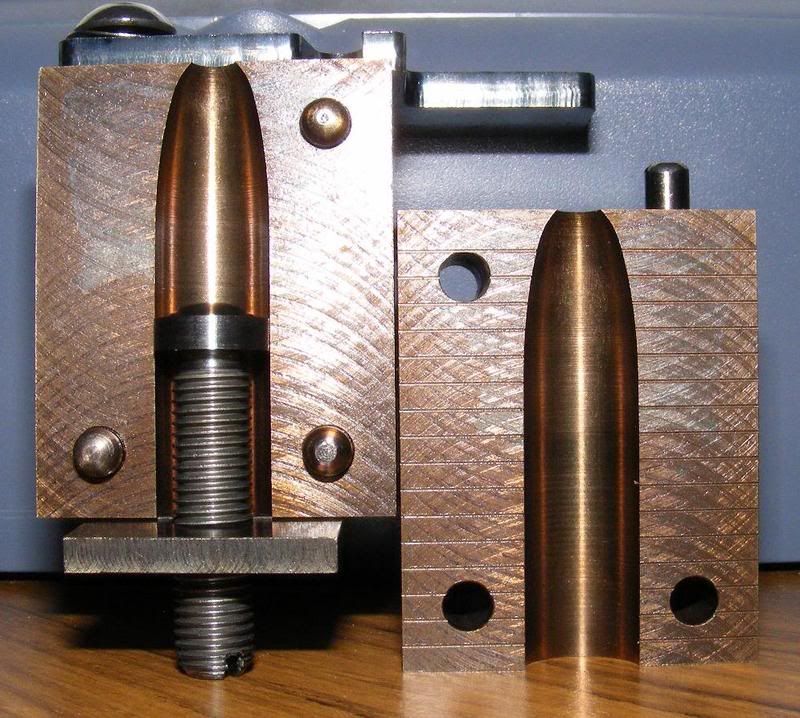

So I've wasted my money on this mould? http://www.buffaloarms.com/browse.cfm/4,7174.html

I'd planning on using 20:1, by the way.

|

|

|

Reply With Quote

Reply With Quote