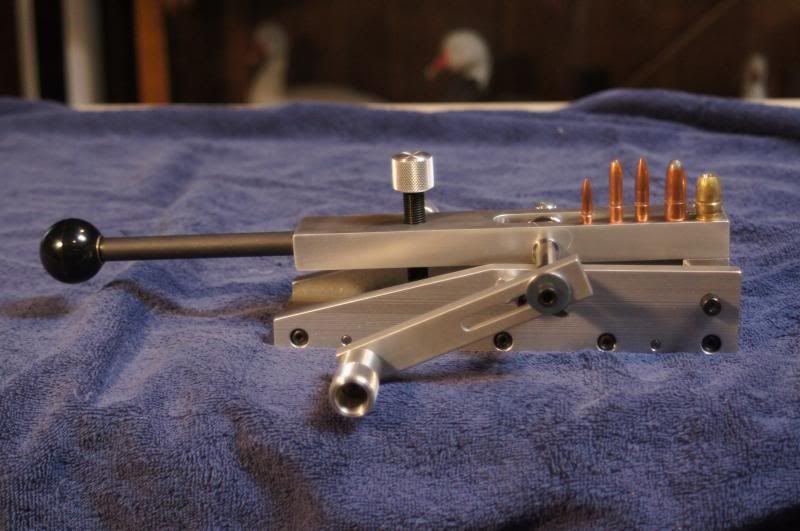

PLEASE NOTE that the tool shown in these pictures and videos are the Original version of the UCT which we are no longer building. Since introducing the Wider "Model II" the demand for the narrower one fell off. In order to keep things simple, prices low as possible etc. we have discontinued the Original/Model One. All features of the two versions are the same except the wide tool will do longer bullets. In stead of re-writing everything, making new videos etc. I am just adding this info. Hopefully there is no confusion. Contact me with any questions.

Thanx

Kevin

We do have Wide Body Tools ready to ship.

Here it is The Ultimate Cannelure Tool

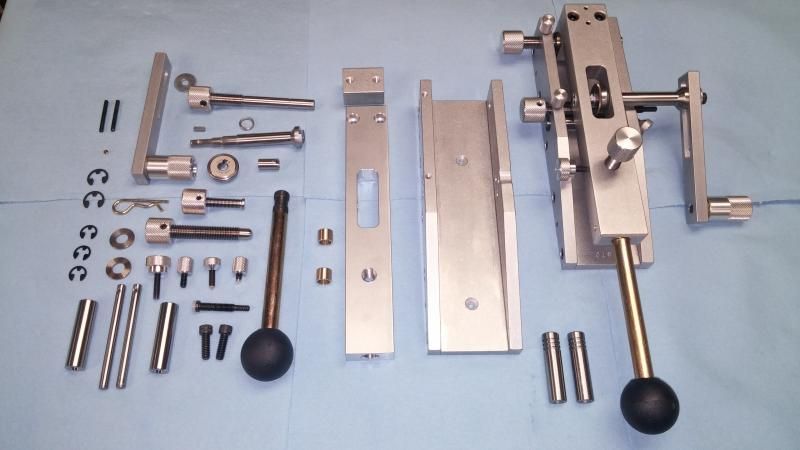

All those parts on the left, become the tool on the right and as shown in the next picture, the rollers next to the handle on the assembled tool are the grooved version if working on rimmed cases. They are an "upgrade" not included with the basic tool.

Basic Tool is $250.00

Some commentary etc can be found here, our original thread in the swaging forum

http://castboolits.gunloads.com/show...re-Tool-update

And Here, our last regular Swap/Sell thread

http://castboolits.gunloads.com/show...42#post2863342

Tool and any upgrades all fit in a USPS Medium Flat Rate box, I do add some insurance to them so $20.00 shipping added to orders. If you already have a tool and need accessories for it $7.00 for a small flat rate box. Other items shipping to be figured/quoted at time of order.

USPS Money Orders are best,

More pictures, video links etc coming.

Thanx for looking

Kevin

|

|

|

Shoot'em If You Got'em...

Shoot'em If You Got'em...