I have an original Winchester 1895 in 405 WCF.

After a lot of testing and leading, I had a smith to check the barrel with a borescope.

He told me that the barrel had some rust in it.

Not much, but obviusly enough to break the seal, and let gas pass by.

So, my rifle is suffering poor accuracy and lot of leading.

Well, a new barrel is to expensive, so that is out of the question for the moment, but I refuse to give up, so, please tell me, can paperpatching help me?

|

|

|

Reply With Quote

Reply With Quote

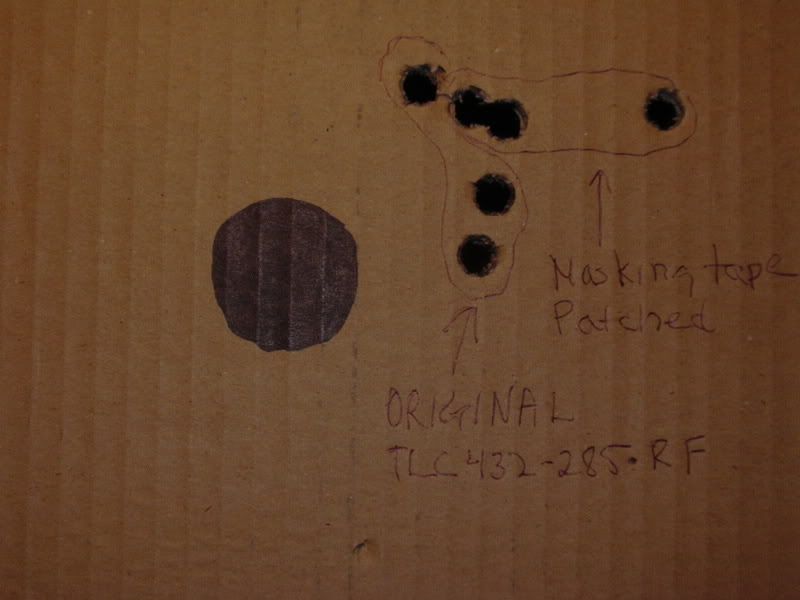

When dry the patches were sprayed with an aerosol spray of molybdenum disulfide, which is sold as a machine lube for heavily loaded gibbs and ways. In the photo at the front are 3 boolits. The naked one is............ er, naked! In the middle is a patched slug and on the left is after being passed through the .432" die, and ready to be loaded.

When dry the patches were sprayed with an aerosol spray of molybdenum disulfide, which is sold as a machine lube for heavily loaded gibbs and ways. In the photo at the front are 3 boolits. The naked one is............ er, naked! In the middle is a patched slug and on the left is after being passed through the .432" die, and ready to be loaded. )

)