For those involved in the XCB project, I'm going to work out the final design here for my uses and any input would be appreciated so we can all have access to the same design. Since the XCB has a standard '06 throat with zero freebore, .3106" throat entrance, and 3-degree included angle to .300" lands, this would be an excellent light-medium boolit for the '06 as well.

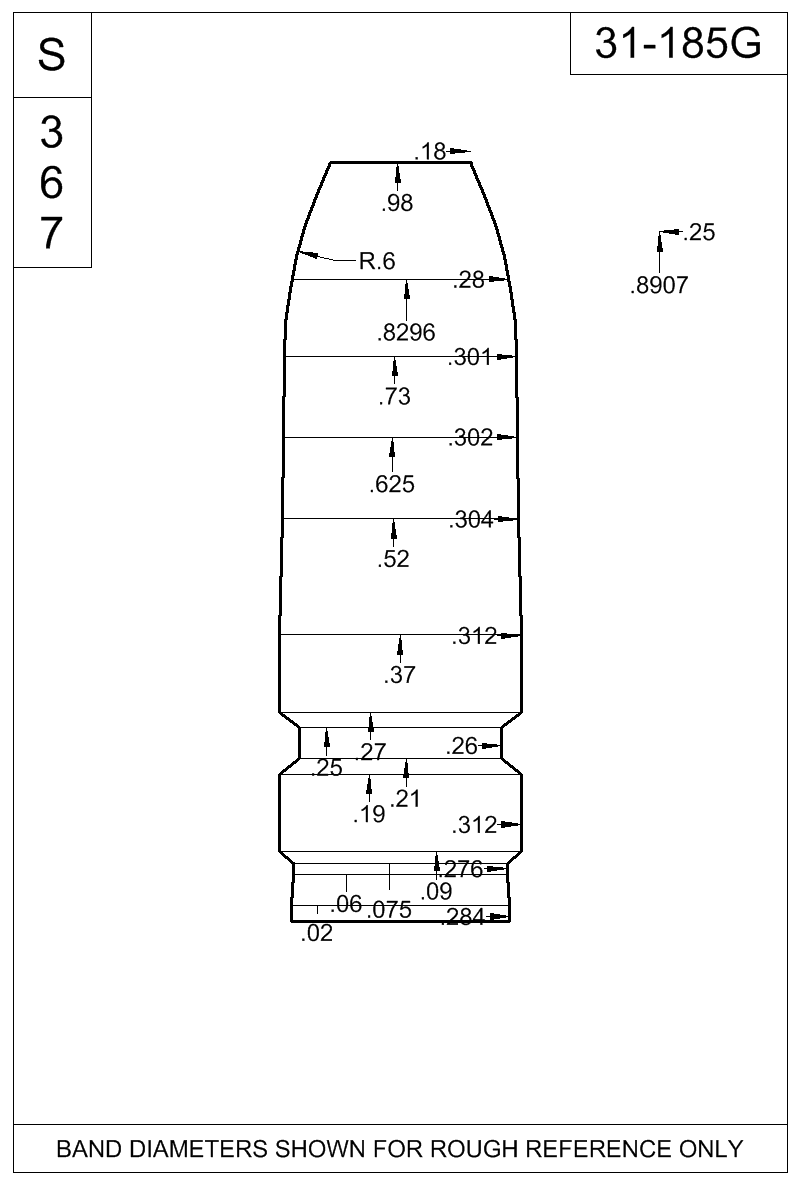

I'm going to modify my original design slightly to better fit standard dimensions. The Accurate 31-185G was worked out for a rifle with .309/.301" figures and from my mould engraves a touch too hard in my XCB, and the leade angle is a bit too steep.

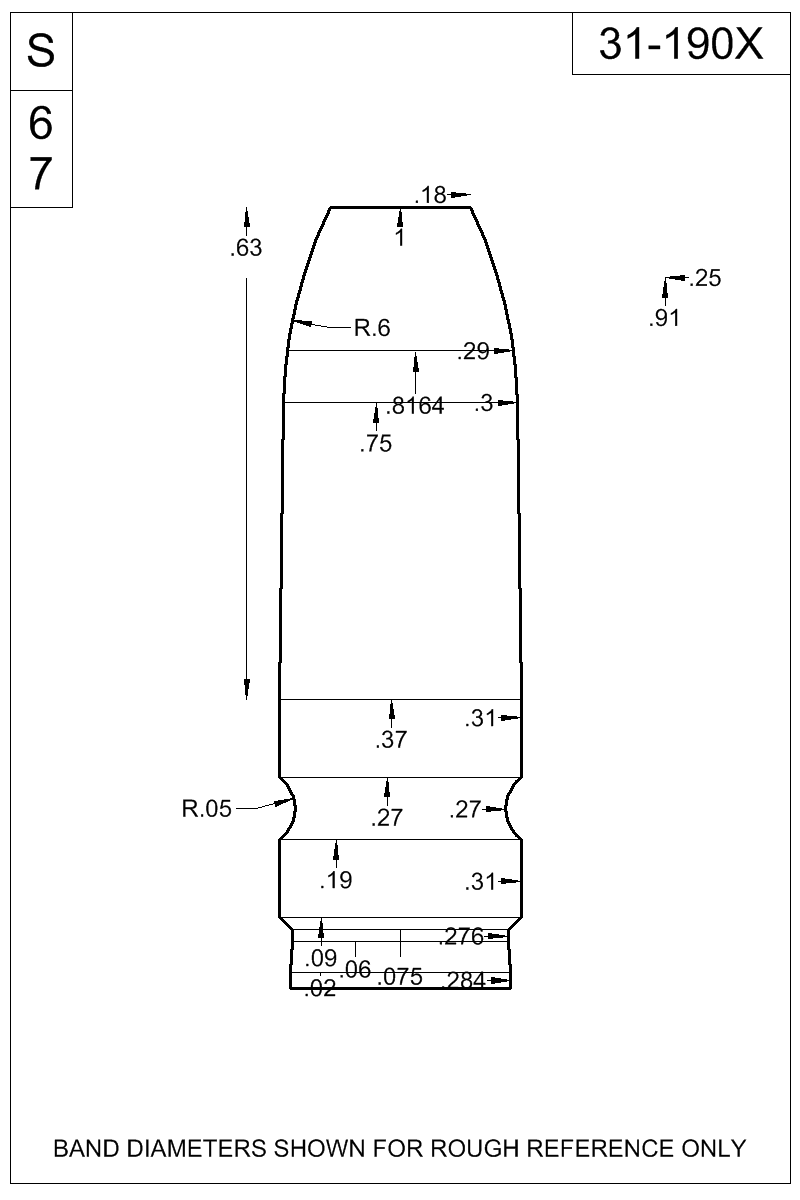

Here's what I'm starting with:

I'd like to slim the nose to .299" at the ogive break and taper through to .301" for the portion that rides the bore. The next section would be a straight taper at 3-degrees included angle to front band diameter, which I'm planning to reduce to .310". I'd also like to make a single, radiused lube groove rather than the steep, square-bottom groove because I think a radius flings lube better and crushes less, but I might just leave it alone. My "patented" ZeroDisplacement gas check shank will remain as designed for Hornady gas checks. Other things we might keep the same are weight (180-190 grains, for those inclined to run a twist slower than 1-in-12"), and the approximate driving area. I'll put up some drawings of the modified design once we hash this out a bit.

Input? Yeah, I know, it needs a .080" or so meplat, but Tom has his ways about that. I'll probably fix one cavity with a ball mill at a later date and let everyone know how it shoots.

Gear

|

|

|

Reply With Quote

Reply With Quote