If that's the Lee .312 your lucky, I just checked 12 Lee Enfields and it wiggles around loose in every one of them , maybe the one I have is Abbynormal ?

|

|

|

If that's the Lee .312 your lucky, I just checked 12 Lee Enfields and it wiggles around loose in every one of them , maybe the one I have is Abbynormal ?

hey, watch where ya point that thing!

Y'all may be interested to know this.

I tried bullets from my NOE 316299 mould in the muzzles of five different .303 British rifles, dating from 1914 to 2010 (Ruger).

NONE of them allowed the NOE bullets to enter as far as the front band, and the as-cast diameters were .303" on the nose and .315" on the bands.

I've not been able to do any extensive research with these bullets yet, but I expect very good results, given those dimensions.

Regards from BruceB in Nevada

"The .30'06 is never a mistake." - Colonel Townsend Whelen

I slugged my 2 groove Savage #4 Mk1 and came up with 305/320!

It shoot's copper nicely, but now I know why the cast tumbled.

Yep, it's the Lee bullet. Noses are 302-304. You can see how far it made it, where the riffling engraved it. Like I said, it was hard to measure the bore slug, but I thought the grooves where on the small side, and they look to be cut deep. So maybe you would figure the lands are small too.

Think I'll give this bullet another shot. Weight sort and maybe increase OAL.

The bullet above is my dummy round. It dosent go in the boar. I casted up some more and they do. They don't rattle around, but the go all the way to the driving band. Only had a few left form the first round and some go in some don't, so my guess is the ones I shot where mixed as well. I Remelted the new batch and attempted to beagle the mold. The result is slightly bigger, not much. Will let them sit for awhile and hopefully fatten up.

I kept cleaning the barrel and finally did get some leading out. Not much, but at least some don't fit that well.

I cant imagine boolits fatten up from age but I have seen a few people mention that ( wishfull thinking I suspect). but I'm no metallurgical engineer.

hey, watch where ya point that thing!

So I slugged my chamber, first time doing that. So now what? Used brass i shot in this gun, filled it almost to the top with pure lead, and then hammered a slug on top of it. The 5 grooves go all the way to the shoulder on the lead. So I run into the same measuring problem I had with the bore slug. I will say as I spin this slug in the calipers it measures a lot fatter then the barrel slug. Any ideas?

yup thats the way to get a good impression of what you got. Fill the cartridge neck with boolit and shoot away, they will slide out the barrel!

Look twice, shoot once.

Changed two things. Beagled the mold and pushed some fat, ugly bullets thru a 314 sizer. And increased my OAL a lot. Still chambered ok, little tight. Right off the bat the box opened unexpectedly and dumped my different loads into a pile. So shot em all at the same POA and got some that resembled a group. Others were still bad. Not sure which! Got a bunch of leading at the muzzle too. thick ring around the crown. Obviously not a great solution so posted a request for someone to help measure my 5 groove slugs.

Last edited by mattd; 04-22-2014 at 10:07 PM.

The only thing that I hate about these threads is that the really interesting ones like this one don't have more posts sooner. while waiting, I tend to be impatient!!!!!!God Bless to ya'll and yours.

Goofy aka Godfrey

A veteran is someone who, at one point in his life wrote a blank check made payable to "The United States of America " for an amount of "up to and including my life."

Unless I am seeing your photo wrong, at the base of the rifling (just above brass and lead filling the end of the chamber) there is a ring. measure that ring and size as close as will chamber.

My Lee Enfields all like throat filling boolits and all run about 0.314" grove with 0.315" throat. I size 0.315" with good results. In fact I have one mould I made that casts large in both nose and bearing surface which is 0.318". I seat that one a bit deep and it shoots very well. It is too big for the throat but seated a bit deep the sloppy chamber allows it in.

Fat boolits are your friend.

Longbow

Another member graciously offered to measure my bore and chamber slugs with the proper tools for a 5 groove. Here's his comments......

Bore slug measured between 0.3152" and 0.3155"

Pound cast throat slug measured between 0.3156" ad 0.3162"

It goes to show that the method of wrapping the bullet in tin can isn't very accurate, at least when i do it. Also, it doesn't really have a throat. so, i think a 316 bullet is in order. what do you guys think?

I moved onto redoing a mini 14 and working up a load for it, so might be awhile before i jump back onto this gun.

It seems that some No4 barrels have a simple taper throat. My two two-grooves have this taper throat (3° included I think?), no free bore. If yours is that then the nose section needs to have a matching taper. Do you know anyone with a lathe who can modify your mould? Lee Moulds would be a bit tricky because of the non-removable handles. Maybe it would be easier to get a profiled push in - push out sizer die and start with and 8mm or 32 mould.

You asked about free floating the barrel some time back. I have only free floated and get good accuracy with j-words. Maybe it's the way I free float or maybe I just got lucky. My accurate two-groove was sensitive to hold until I bedded it properly.

Last edited by 303Guy; 05-26-2014 at 05:10 AM.

Rest In Peace My Son (01/06/1986 - 14/01/2014)

''Assume everything that moves is a human before identifying as otherwise''

I shot my no.4 sporter with .316-317" 180 grain Lee CBs from a beagled mold. I didn't size them but tapped on some aluminum gas checks and seated the bolts to kiss the rifling.

I used 7 grains of Red Dot. Got a 2.5" group at 100 yards. I'm going to experiment with more powder to see if I can tighten the group to 2", which is about as good as I think this .303 sporter can do.

Just be careful with fast pistol or shotgun powders. They develop a lot more pressure than you'd expect or can see on the case or primer.

Rest In Peace My Son (01/06/1986 - 14/01/2014)

''Assume everything that moves is a human before identifying as otherwise''

So I'm getting a custom cut 311466, 160g bullet, cut to 316 to do double duty in the 303 and a big SKS. I actually already have it, and it cast 318, but the gas check shank is too big to fit a 30cal check on. The mold maker is up for replacing it, and i would end up with a 316 casting mold and could go with either a 30cal GC shank, or a 8mm shank and buy and use 8mm checks. The maker suggested this would be better for the bigger 316+ size bullets.

What do you guys think? Get a new mold that casts right at the throat size and use the current pile of 30cal checks i have. Or keep the mold I already have that would allow some sizing and get some 8mm checks.

The SKS has a 3145 bore.

Mate it's easier to size down to fit the throat than size up,I'd get a sizer made and use 8mm checks,it normal practise to size down 32/40 or 8mm boolits to suit oversize 303's. Pat

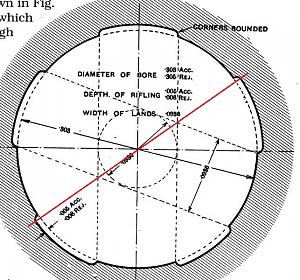

This is what the chamber and throat is suppose to be on the 303. I'm sure they excepted most anything but, every reamer should have had these angles ground on it.

Frank

PS

For those that are confused about how angles are measured in minute ( " ) and seconds ( ' ). The angles are .401 deg closest to the neck and .673 farther away from the neck.

Last edited by frnkeore; 07-03-2014 at 03:38 PM.

Also for those wanting to measure the bore and groove of the 303, this may help you. If the barrel is within tolerance, note that measuring on the corners (red line) will give to the groove size.

If you have pin gages, you can verify the corner measurement by measuring from groove to land and subtracting the pin gage from that. That gives the groove depth. Double that and add the pin size. and that will give you the groove size to compare to the cross corner measurement.

Frank

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |