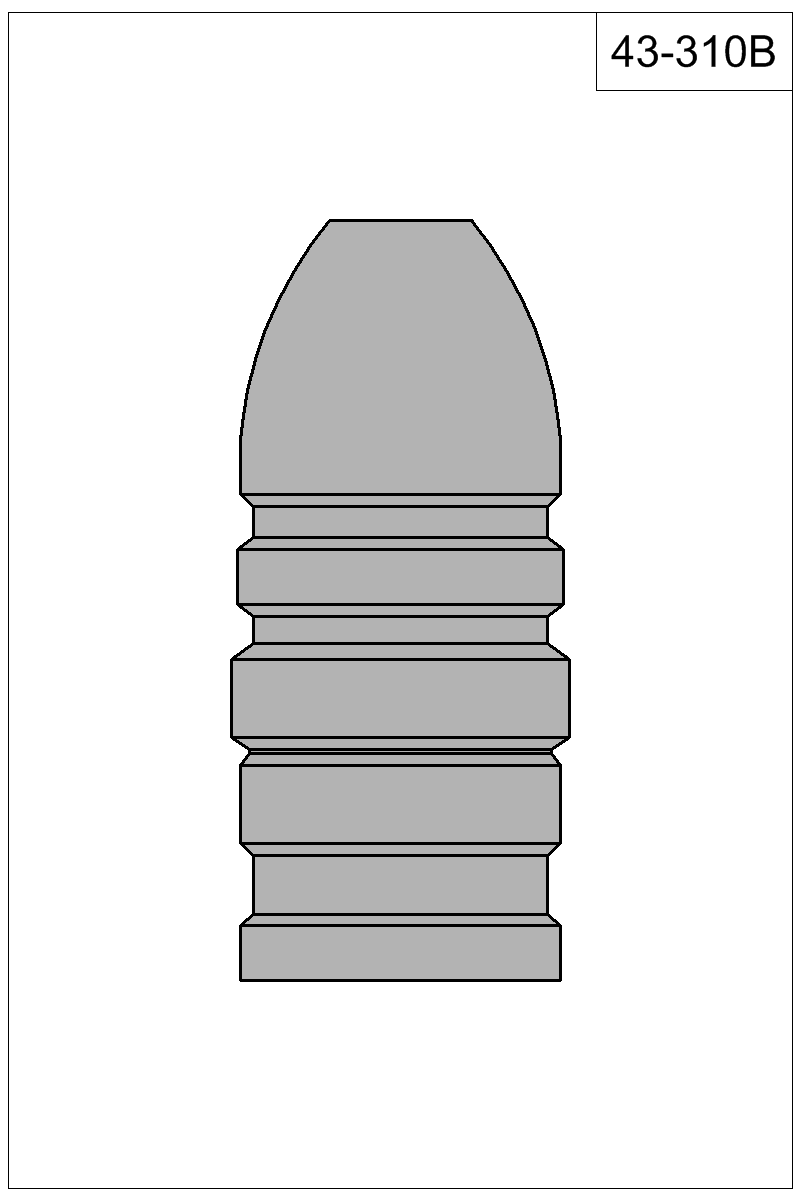

Any good ideas for lubing heel bullets without making a mess? I'm working with the 10.4X47R mm Italian Vetterli, duplicating the 1870 lead bullet load. I've got a heel bullet mold coming from NEI that closely duplicates the black powder bullet for the original cartridge. Basically the rear half inch of the bullet is about .414-.415", a smaller diameter than the front bands (about .424-.425"). The heel goes inside the case and it crimps immediately behind the rearmost large band. This .41 Swiss bullet is the basic bullet design, but with a much smaller hollow base and larger diameter dimensons by a few thousandths.

So if I stick this in a .424-.425 lubrisizer, it's going to make a mess with the smaller base bands allowing free flow of lube all over the die and bullet base. Should I pan lube with a rather firm blackpowder lube and push them out of the lube cake from the bottom of the sheet? Will that give fairly clean base and nose bands? I guess I could also do some type of double kake cutters to clean excess lube from both sets of bands. I'm open to suggestions.

|

|

|

Reply With Quote

Reply With Quote