You folks with your .017" plus or minus, don't make a lick of sense. With the shoulder angle aside, there is only .004" difference in headspace between a standard parent case and an Ackley chamber, .004" SHORT!

An excerpt from Manson Reamers:

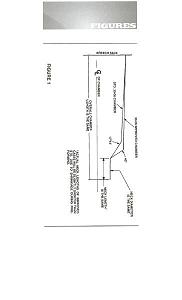

Because the cartridge must be held secu

rely during fireforming, the dimension

between the breech face and the neck/shoul

der junction becomes critical. P.O.

Ackley, who popularized improved calibers,

recommended that this dimension be

reduced

by .004”/.006” from the standard minimum for a particular caliber.

Reducing this dimension compensates for

cartridge tolerances and ensures that

fireforming can be done safely.

This shorter chamber provides a crush of the brass. Some brass is thicker than others, and there is actually a .004" to .006" variance for this. You can talk all you want about .017" of something, but the bottom line is there is .004" of difference.

I started this out by saying, if you chambered UP TO the neck/shoulder junction, NOT PAST IT NOT BEFORE IT, you could fireform brass safely by standard methods of fireforming wildcat cases. This ca be done by a hard bullet jamb, a false shoulder, etc, either method works as long as you have a tight brass fit in your chamber. You need this so the firing pin hit doesn't move the brass forward.

I will also say, that it is not completely uncommon to see a factory chamber with .004" clearance. You can also do this in resizing if things are a little out of spec, a die a little too deep, or a shell holder a little less than the .125" depth it should have. Add those together and you ca push brass back far enough to create the exact .004" plus chamber.

If you have a notion that you may sell a gun in the future, then set the barrel back. If you're going to shoot it until it's a smoothbore like I do, I don't worry about that.

Reply With Quote

Reply With Quote