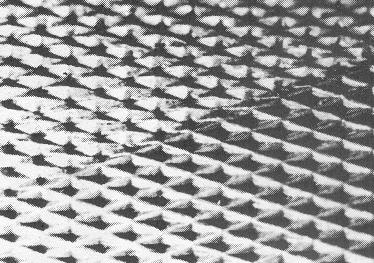

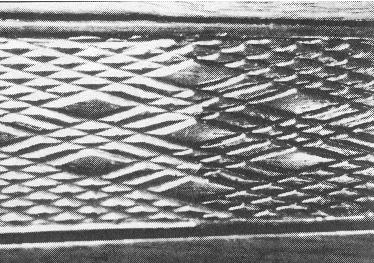

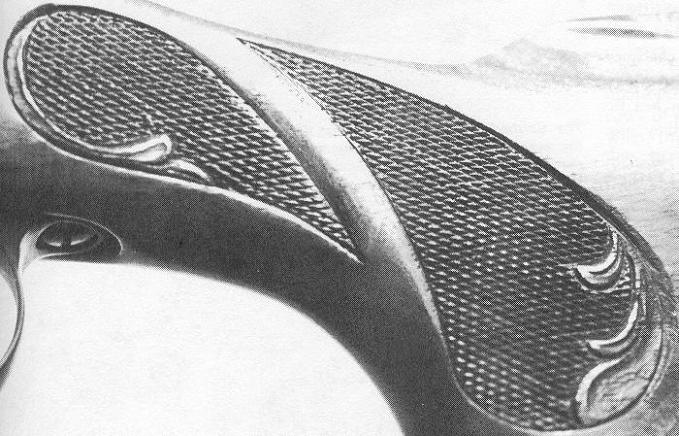

I'm trying my best to remove the remainders of the impressed checkering on the pistol grip of my 1965 Rem 700 ADL. Every time I think I've got it- I wet the stock with water and Arghh. I shortened and reshaped the for end so it's good. I could go nuts wth a rasp but I don't want to change the shape of the pistol grip. Anybody been there? I DID a 70's 22-250 decades ago and I gave up and lived with it. I don't really care for checkering or stopping so That's out.

I know-shut up and sand, right?

Best, Thomas.

Sent from my SAMSUNG-SM-G930A using Tapatalk

|

|

|

Reply With Quote

Reply With Quote