I have been kind of interested in trying this with some 223 boolits.

Most of the posts I have read pertain to powder coating pistol bullets.

Since I have many ways of lubing sizing pistol and 30 cal rifle bullets.

That work well with no leading. That has not really caught my interest.

223/5.56 out of my AR, thats a different story. I only have one way to lube/size them, and I feel there is room for improvement on a load.

I am curious to see if I can get a better plinking load for my AR.

Will See.

Yesterday Jan 1st I noticed that Harbor Freight had a 25% off coupon running that day. So I took the plunge and ordered the Powder coat machine and a bottle of the red powder coat paint.

Now I just need to figure out a way to coat the boolets with out messing them up, or dumping a tray full on the floor.

I am going to try and solve that problem while I wait for my machine to show up.

I noticed some guys were having luck with trays and non stick aluminum foil.

Thats what I will try.

1st I need a tray. Since I have more than a couple old computers taking up space in the basement. I decide to make one from a old computer case.

Waste not want not.

Angle grinders are the best tool ever invented.

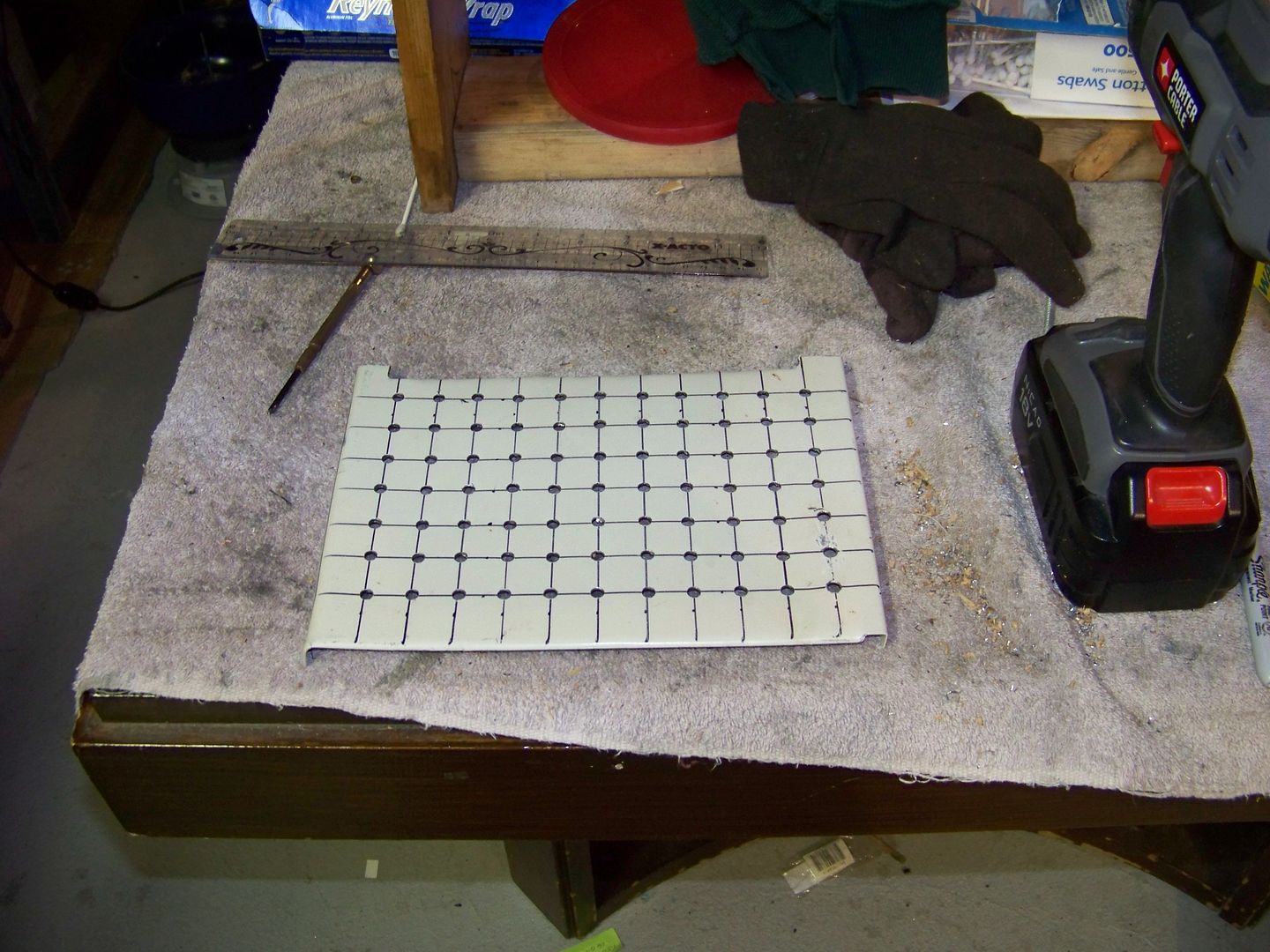

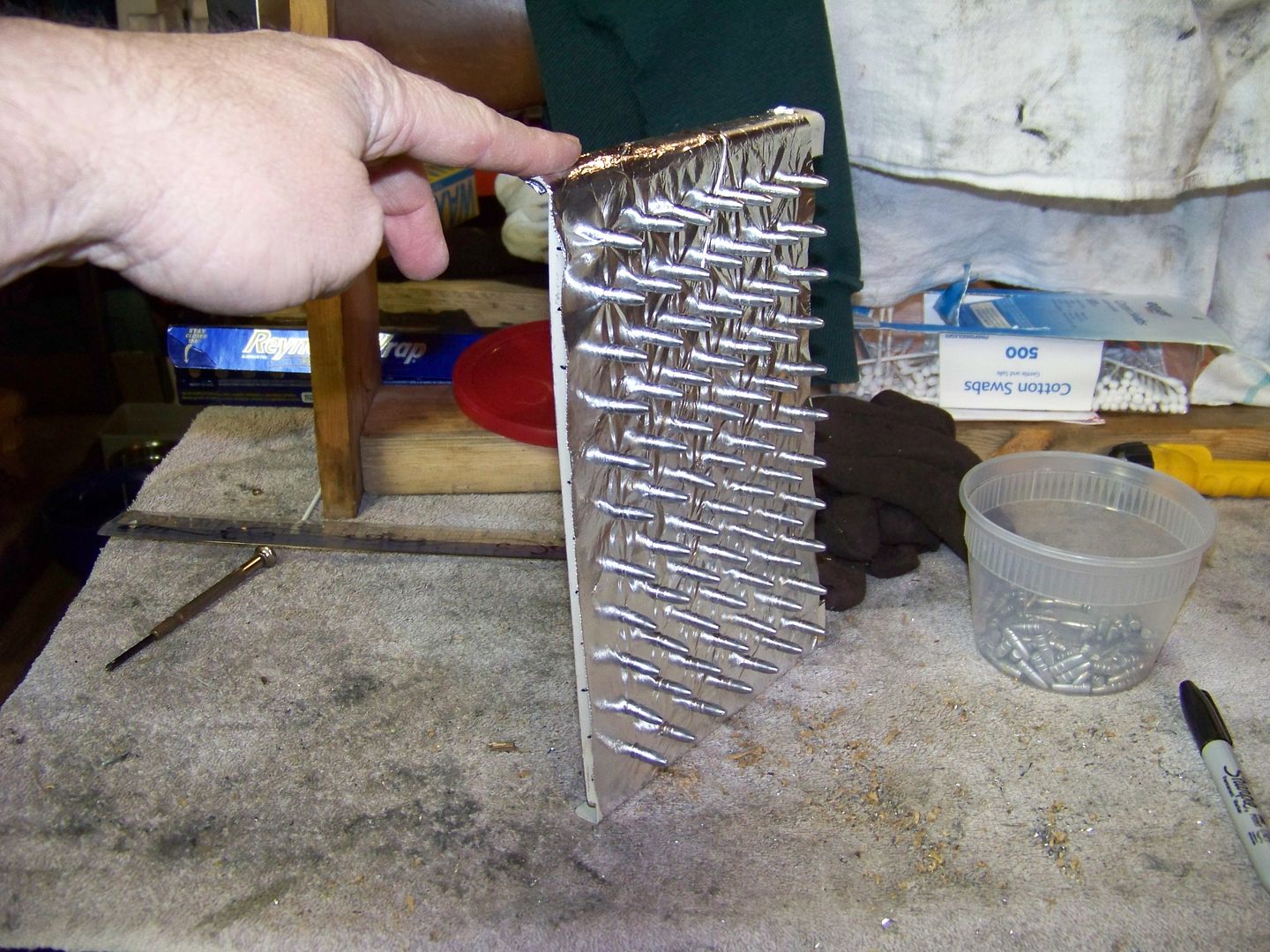

I cut out a section sized to fit my toaster oven. ( I already had that for pan lubing)

I bent the ends to make a raised pan.

Then I marked and drilled a whole bunch of holes to seat the boolets into at the gas check base. 7/32 is the perfect size drill bit for this.

I dont have the nonstick foil yet but a standard sheet fills in nicely to test the concept. Just push the base through the foil into the hole.

As you can see they wont fall over. They get held nicely.

Proof of concept!!! Now I am ready for the machine to show up.

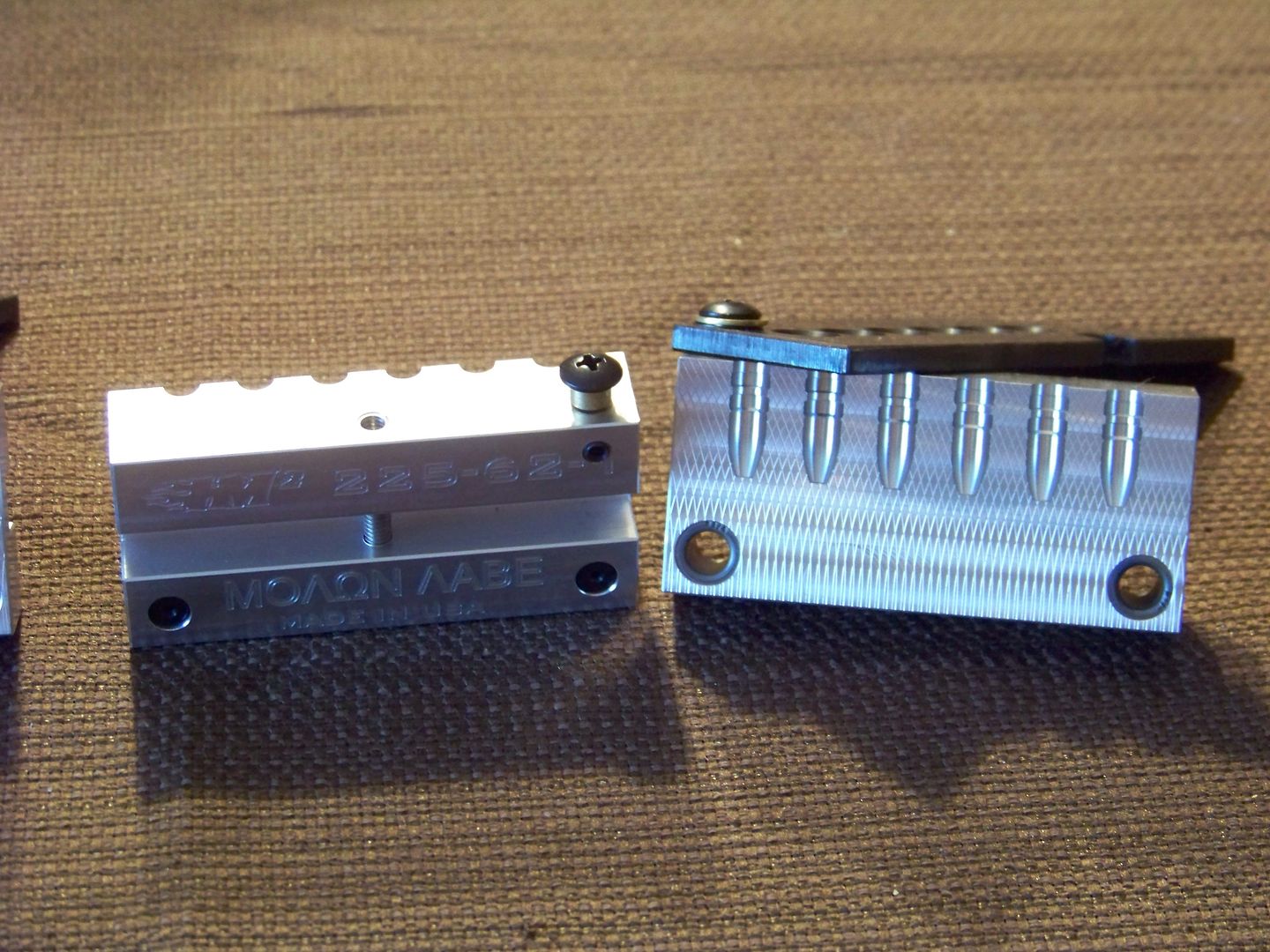

I plan on coating them. Then placing a gas check and sizing with a LEE .225 push through sizing die.

Wish me luck... If you see any thing that looks like I made a mistake and wont work. let me know.

|

|

|

Reply With Quote

Reply With Quote