finally got to work in the shop today and finish the core sizer, takes a cast .243 boolit and sizes it down for core seating… here I am using a Lyman mold that drops the cast boolits at 0.248, a tad too large for the 7mm jacket, so I sized them down to 0.235 and they slip in most of the way:

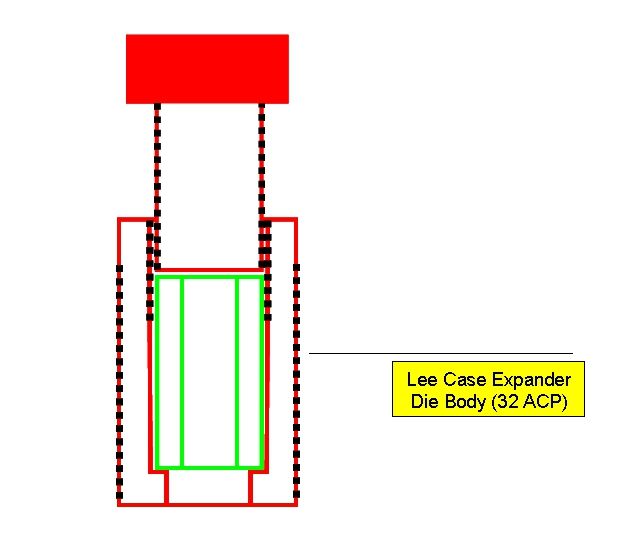

not much to look at but the die slips inside of the threaded die body, and you can see the boolit ready to be pushed up thru the die (pass thru punch is on top, Lee threaded die body in the press, and 9/16" die inside)…

here is a shot of what was produced from left to right: cast boolit at 0.248, cored sized at 0.235, core inside of 7mm jacket ready to be seated (cores weigh 87gr, which makes a 147gr swaged bullet, might be a little heavy for my 7mm-08, but i may go with it for now):

yawn, nothing new right? well, the real winner here is the punch holder I made, you can see it here… it will take 5/16” 1144 ‘Stress Proof” rod and can be turned down to whatever diameter is needed for the punch… need a new punch? I was turning down grade 8 bolts, but that is somewhat of a pain, now I can just turn down a short section of rod to whatever diameter and length I need and lock it into the punch holder (I liked the way it looked black after heat treating and tempering so I decided not to clean it up, the matt black will wear off but I like it for now):

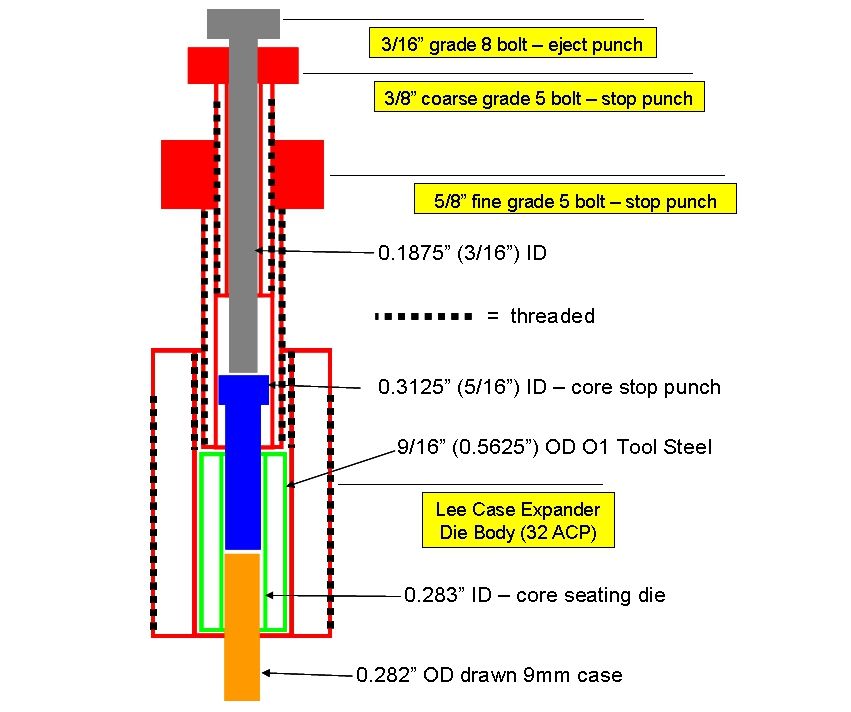

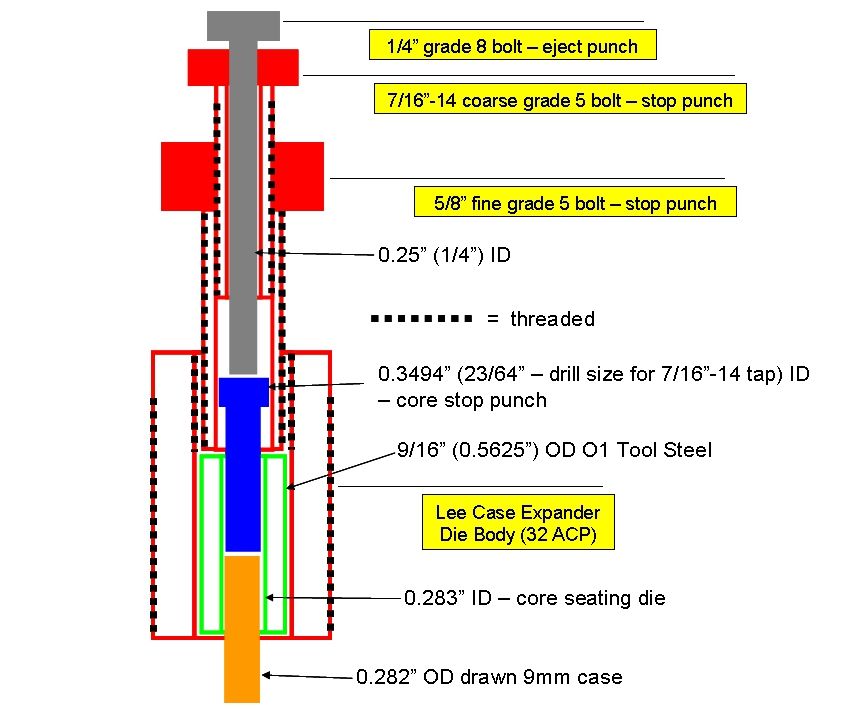

next up is the core seater… this die is a simple idea, but I have found from the 0.224 project that it is harder to design that make… I will post the drawing in a few days…

|

|

|

Reply With Quote

Reply With Quote