Hey all,

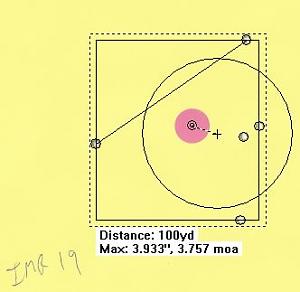

My chrono didn't show up for this last weekend's shooting trip so I was unable to get any velocity data. I do have it now for this weekend though. I bought some polyfil from Walmart and tried what Larry recommended. I added the 1/2gr of filler to sets of 5 rounds from 16.5-19gr in .5gr increments. I shot these 5 shot groups at 100yrds this time. My AR cycled 100% reliably, with the bolt held back on the last round, only after 18.5gr of IMR4895 with the filler. I found the On Target Precision Calculator online and figured I'd use that to better analyze my groups. My group sizes with fillers came out to: 16.5gr = 2.915moa, 17gr = 3.052moa, 17.5gr = 3.629moa, 18gr = 3.815moa, 18.5gr = 4.032moa, 19gr = 3.757moa. I still had those groups loaded without fillers so I shot them at the same range and got the following sizes: 18.5gr = 4.187moa, 18.7gr = 2.577moa, 19gr = 4.478moa. The 18.5gr group without filler cycled just fine and held the bolt back this time. As you can see my smallest group was the 18.7gr without a filler but I did notice the groups with fillers grew more linearly and seemed consistently smaller than the other 2 groups without fillers. I recognize that 5 round groups are probably not a large enough sample size for a reliable statistic sample. The 2.577moa group may be an outlier. I have loaded a few more of that same load with and without filler for 10 round groups to compare a larger sample size for this coming weekend. You might notice from my targets that the zero wanders, that because I was playing with the zero on my scope in between groups. I probably should have left it be to see if the zero would have stayed roughly in the same spot. I noticed that the rounds with the filler would stink like burning plastic when I fired them. I looked down the barrel after and saw what I thought were small burnt plastic beads. It didn't look like it was getting stuck to the barrel at all. Is this normal with using this filler? or am I doing it wrong? I would prefer to not use the filler if it doesn't make an appreciable difference because of the smell. It doesn't seem like I'm going to get any smaller groups with full function with my setup. My rifle typically shoots factory ammo at 2-3moa so this is just a bit bigger. Maybe a different powder or primer could help? Oh, and my OAL is 2.2in What are you guys loading yours at? I still haven't cleaned my rifle. I shot 70 cast and 130 jacketed without cleaning in between. The barrel still seems fine. I did not notice any leading. I need to clean it for this weekend though. The bolt carrier group is filthy. Sorry for the long and winded posts. I like hearing all the details so I figured I should share them as well.

|

|

|

Reply With Quote

Reply With Quote

Will load more this week going up in increments and hopefully test next weekend to see what my AR and Mini 14 like best.

Will load more this week going up in increments and hopefully test next weekend to see what my AR and Mini 14 like best.