I don't know if it helps with distortion any on soft steel but I use a soupcan furnace to get an even heat on the entire piece being hardened & quench everything in oil. Water will boil creating air pockets (steam) around the metal being cooled causing the part to cool unevenly creating warpage.

Some metals/case hardeners call for water quenching. It's better to use a brine than strait water, a typical brine is 3/4# of salt to 1 gallon of water. The brine will cut down on the amount of air/steam that is around the part being cooled.

Personally I like to use oil (old harley oil), it's full of carbon. It works to heat treat different grades of harder steel & can be used to simple quench hot steel.

You might consider taking one of your out of round dies & drilling it out to a larger dia & checking it for roundness. Then re-heat treating it but use oil instead & see what helps. The other thing that most people overlook with heat treating steel is the more even the heat the better, the more even the cooling the better. Someone that is heat treating a shaft for a pulley or a pin to hold a mower deck on isn't really concerned about 2 or 3/1000th's of warpage.

Something else to consider:

You are heating what is nothing more than a tube and a tube is harder to heat evenly than a solid shaft. A solid shaft(bolt, rod, pin, etc.) takes longer to heat but the heat will spread evenly throughout the metal. A tube on the other had will draw air thru it cooling part of the tube & making it harder to transfer heat evenly. I don't know what your setting/resting/holding the parts your heat treating with but that will definitely affect how even your parts are heated.

In heating, 1700* here & 1575* on the other side ='s warpage

In cooling, 100* water here & 500* steam there ='s warpage

I'm sure you will figure it out, everything else you've done has been well thought out.

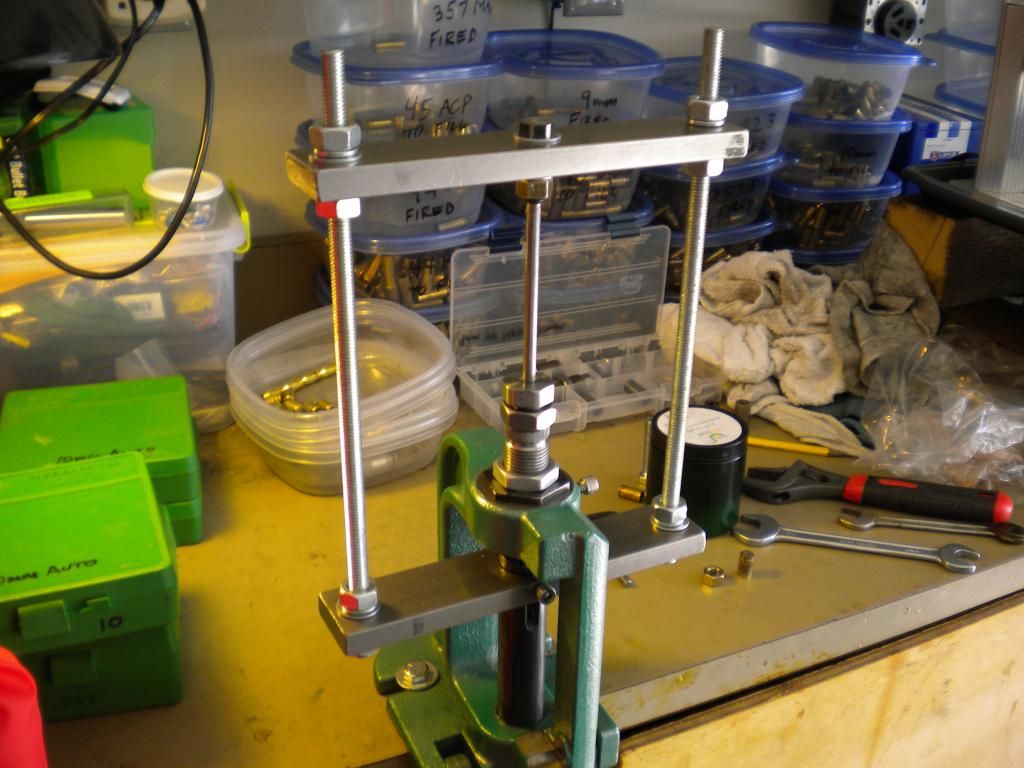

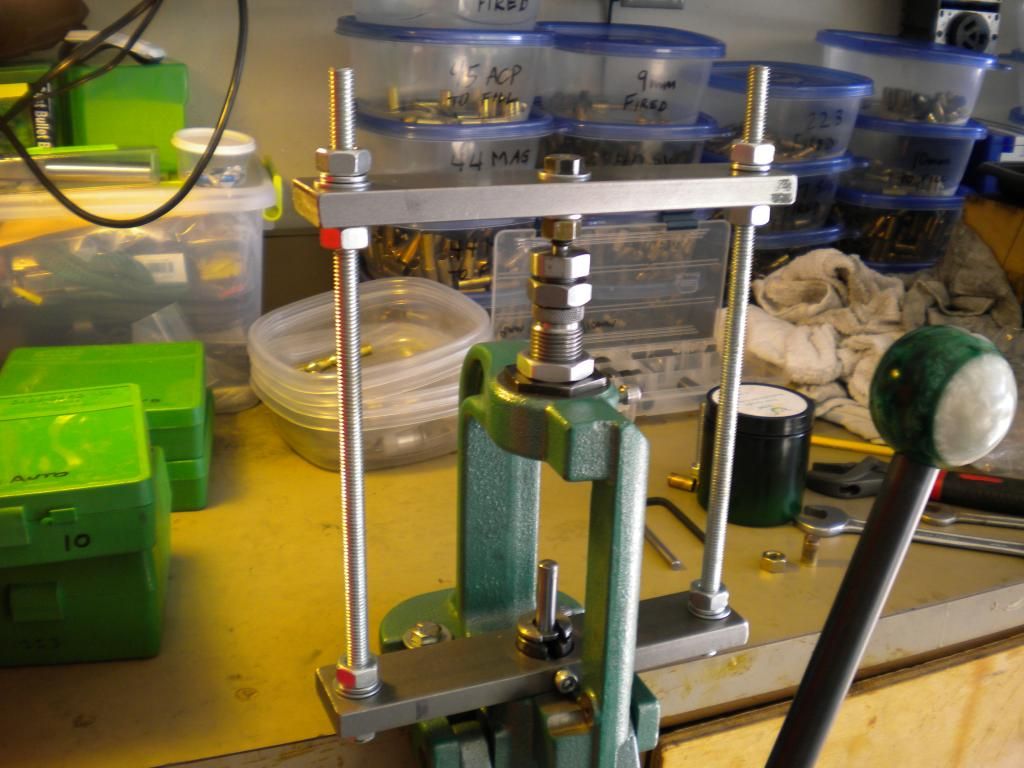

When I started using the soupcan furnaces the quality of what I was heat treating went to the next level (even heat). A pic of the 2 furnaces I use, nothing high-tech just a soupcan & a coffee can lined with ceramic insulation. But when you heat something in either of these you don't get any hot or cold spots in the part being heated.

Attachment 72290Attachment 72291

Reply With Quote

Reply With Quote