|

|

|

Last edited by novalty; 04-25-2013 at 12:21 PM.

how long did it take? I sure wish I could get in on a GB with that same mold gosh darn it. keeping my eye out. I am in on one for .22cal 75 gr prob going be awhile. how long did it take after GB CLOSED

from your pics it looks like thing of beauty !

CONGRATS

usmcscout, I got in on the most recent GB after it closed. The notice was placed on 03/24/13 that the GB was closed but Mihec had extra blocks. I sent a message on 03/29/13 indicating I wanted a mold, and received it yesterday 04/24/13.

I requested one of the extra molds as well..you are lucky sir.

fantastic looking mold.

What a beauty. I am looking forward to the day that I own a MiHec.

I am excited and apprehensive about using for the first time casting. Have read about it needing a lot of prep, and specifically a hot plate to bring it up to temp. Plus the mold is very heavy, so it will test my endurance with my arthritis.

Don't be afraid to dip the corner (just a corner!) in the alloy to get it up to temp. I use a hot plate also, actually a no-stick skillet on a gas burner, but dipping is what really gets them up to temp, in my experience. I have a similar mold (128 gr. HP, .358") by NOE in aluminum, which helps the weight issue somewhat. If the brass is too heavy and you want aluminum, we could work out an exchange. The NOE uses a different HP pin set-up, but it still works great.

On another note–did you mean that this is your first time casting, or your just the first session with this mold?

Last edited by Boolseye; 05-04-2013 at 07:54 AM.

Last night, I cleaned the mold and pins with soap and water, then heated in my toaster oven up to 400 degrees, then cooled down, and heated a second time. Some of the pins go in really hard, and I even put some of the supplied lube on them--but still managed to slightly hairline scratch one cavity as one slipped trying to be inserted. Put a slight amount of lube on the sprue plate which moves well-and doesn't seem to have and burs.

I think a little scratch in one of the cavities is part of the break-in process

If you loosen the pin screws a quarter turn they will run smoother. As you use the mold for a bit, you can tighten them up and all will be well

CPL Lou

Well worked with the pins loosened as suggested and gave the mold a second try tonight. Got a lot more keepers, found my RCBS Pro-melt needs to be set somewhere near 725-750 on the dial. Experienced some sticking on the solid flat nose cavities, so haven't gotten it completely figured out. The HP cavities were dropping the bullets nicely, just by gently tapping the pins in. Overall, it was good to see I got some keepers, even though some are frosted.

Here is my work around for the mold guide to clear the penta pins that stick out the bottom of the mold.

Last edited by novalty; 06-09-2013 at 09:50 PM.

What is weight of solid boolits? wich alloy you using!Nice work

I am casting with straight clip-on wheel weights. I didn't weigh the boolits from last night, but in previous sessions I had cast the round HP boolits and solid FN, and the HP's weighed in around 126grs. and the solids weighed in around 134grs. The mold is listed as casting 125gr. HP's and 135gr. solids.

I got in on the first run of these last year and they shoot very good. The best expansion was from straight wheel weights loaded to 900fps give or take 50fps, with the round HP pin. the penta pin seems to break apart around 850fps. I have only shoot them out to 50 yards and they will keep 3" groups at least for me and my shaky shooting.

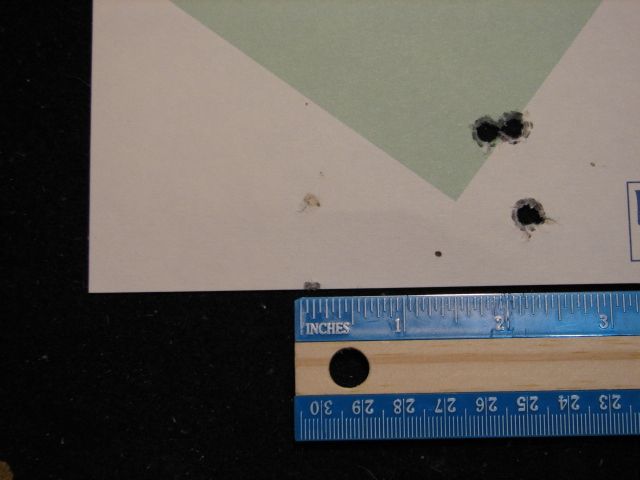

Ran my test loads with the Mihec boolits through my S&W 5906 last week, before loading up a bigger batch. Here are the results from about 7 yards, with 4 of each boolit. Afterwards I loaded up 100 rounds and used them on my plate rack this past weekend, very miniscule signs of leading if any.

135gr. FN

125gr. HP (Pulled the last one, and it barely notched the paper by ruler)

Last edited by novalty; 07-10-2013 at 06:26 AM.

My Feedback, (did I buy or sell to you? Please add your Comments)

http://castboolits.gunloads.com/show...hlight=novalty

I love that mould! I spent a couple of months cleaning the alloy off my mould when I bumped my table and 'dipped' the entire mould, but that said, I still love that mould. Switched to a hot plate after that (coffee can to hold the mould upright and contain the heat).

This is a neat video on firearms but the fellow uses that mould on his porch with a dripomatic...with some success. I am using the paddle trick from him now.

http://youtu.be/CXUBKjhaOxI

You are going to love that mould for the versatility (rabbit hunting loads with the FP, defense loads with the HP, and you can load light for plinking with either too. I even case the round HP, Penta-HP, and FP boolits in the same session when I do not need a lot of any one type.

_________________________

DRNurse1

Education is one thing you can give away freely while suffering no personal loss and likely increasing one's own knowledge.

Properly vetted source information prevents GIGO, the scourge of the internet.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |