I shot my first 50 rounds of blackpowder loads today. I've got a lot of work to do.

I used the RS Wright book (Loading And Shooting Paper Patch Bullets) as my primary reference when putting these together. I made some mistakes.

- I lubed the paper patches with a light coat of my regular muzzleloader conical lube (a concoction containing Beeswax, Castor Oil and Murphy's Oil Soap). I probably shouldn't have. It soaked in and softened the patches slightly. Next time I plan to load them dry.

- I used a 0.10" lube cookie (White Label BPCR) between two cardboard wads that I punched out of a cardboard soda can box (.020" each). It looked like a lot of lube when loading them. It wasn't enough. I never got any sign of lube at the muzzle. Plan to try a 0.20" lube cookie next time.

- I compressed the powder charge with the .375" neck expander in my RCBS cowboy die set. This left the over-powder wad somewhat dished. Need to get a proper flat-ended compression plug.

- I neglected to open the case mouths (Lee Universal Expander) for bullet seating until after I had already loaded the lube cookie and second card wad. This left the second card wad slightly dished and caused some lube to migrate around the wad. I should have done this after powder compression and prior to loading the lube cookie.

I loaded two different powder charges and two different bullet alloys: 10 rounds of each combination, plus 10 extra for sighters and foulers. COL was 2.870" in all cases. I threw all the charges using a Lyman 55 measure then checked them on a scale. Charges were all compressed to leave 0.366" of empty neck above overpowder wad.

- Starline 2.125 brass (necks annealed), CCI 200 primers

- 44.7 or 47.7 grains GOEX FFFg (weighed out at +/- .2 gr by weight in all cases)

- 0.020" cardboard overpowder wad, 0.10" lube cookie, 0.020 card wad.

- 5bhn pure lead (.3740" patched diameter) or 8bhn range scrap (.3745" patched diameter)

This COL put the boolits out long into the rifling. I was able to thumb seat the pure lead loads into my Uberti for the first 2 rounds after wiping. The third round in a fouled barrel needed help (push with dowel). I couldn't load any of the 8bhn alloy boolits fully with thumb pressure, they all needed the dowel for full seating. The lighter charge gave me a shade over 1300fps. The 3 additional grains of FFFg boosted velocity by ~50fps.

After about 10 shots with intermittent barrel patching I resorted to wiping after every shot. I plan to try a duplex load next time to help control the fouling in front of the chamber, drop bullet weight from 270 grains to 255 grains for a shorter COL and stick with pure lead for easier loading.

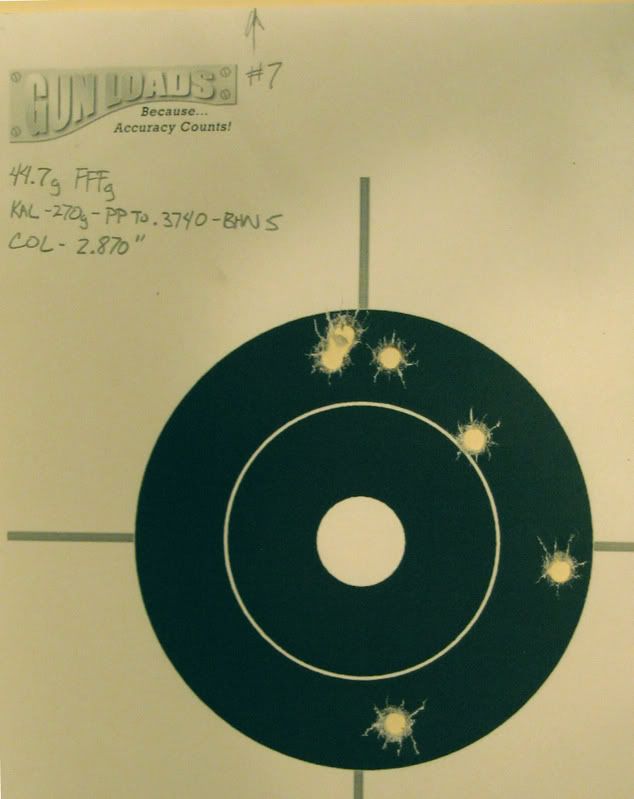

My best target of the day, in all it's glory. Seven shots at 60 yards. The 7th hole was just off the top of the page. I like to think of it as a good three shot group with four additional fliers.

-ktw

|

|

|

Reply With Quote

Reply With Quote