I just ordered my 8mm Nambu dies from CH. What bullet and load are you guys useing?

Thanks,

Mark

|

|

|

I just ordered my 8mm Nambu dies from CH. What bullet and load are you guys useing?

Thanks,

Mark

There is very little loading data for the 8mm Nambu out there.

Midway lists a little data:

100 grain bullet - Bullseye 3 grain minimum (way to light as it will not cycle the action) to 4.1 grains maximum.

I have loaded with 4 grains Bullseye, it cycles the action on all three of my Nambus.

100 grain bullet - Unique 4 grains minimum to 4.7 grains maximum (never used Unique, so no feed back on its use).

I have intended to workup a load using Red Dot, but have never gotten around to doing so.

As to the bullets, I bought 500 of them, I think from Huntingtons.

Gregg

I haven't gotten a round tuit to reload for my Type 14, but here's some data I've found:

From a reliable source:

106 Grain RCBS 08-110-NAMBU roundnose Hodgdon Titegroup 3.5 gr 991fps

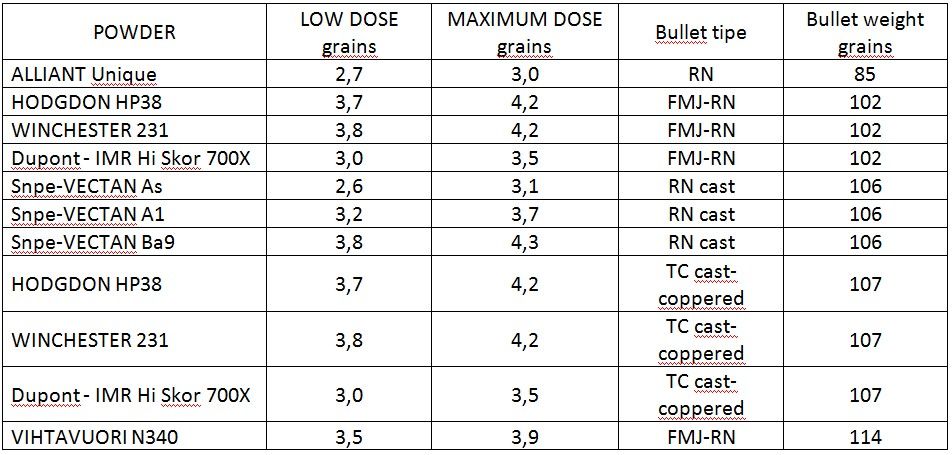

I have a jpeg of a sheet I found some years ago with the following loads:

Midway 102 grain FMJ, Midway cases, Federal #100 primers, OAL 1.22

Powder Start Max

WW 231: 4.0 4.8

Bullseye: 3.0 4.1

Unique : 4.0 4.7

These loads supposedly generated 1050 fps (on the Max end, I'd guess).

Mark this is what I have been using in my 1910 Papa Nambu.

RCBS 08-110-NAMBU mould. 110gr .323dia. Loaded as cast over True blue, CCI SP primer.

I started out with 3.5gr and got 725fps worked up to 4.3gr 880fps. It’s a not a strong load don’t want to hurt the gun (hard to find parts for them). Accuracy was 3” low from POA in a 3” group out of a pitted barrel. Factory loads for 102gr FMJ is 990-1060. So it’s close

Thinking about going to a tad faster powder, the TB didn’t get a complete burn. Looking at silhouette.

Hope that helped

Larry

What is happiness "To crush your enemies, see them driven before you, and to hear the lamentations of their women!"

Conan the Barbarian

My boolits from the RCBS mold using wheelweights come out at 111.3gr. I size them to .320" using the Lee sizer. 3.6gr of Titegroup sparked by a CCI 500 primer in a reformed 357SIG case, overall length of 1.242" yields an average of 994fps with a standard deviation of 16 for 10 shot group. It shoots to point of aim at 25 yards in my Type 14 Nambu made February 1944. I also tried Rem and Win primers but the CCI were most consistent. Perfect function makes it a fun and economical gun to shoot.

Look up Mike Venterino's load data in the Feb/Mar 2011 issue of Handloader magazine. Mike used Starline brass but I don't think they make them anymore.

Last edited by onefunzr2; 04-03-2013 at 03:26 PM.

Huntington Die Specialties has 8mm Nambu brass that--from what I've read elsewhere--is actually made by Starline. I bought some a few months ago and they look well made to me.

I also bought some 83 grain .320 diameter bullets from Grafs that were supposedly designed for the Nambu. Unfortunately, I have yet to find any good load data for that bullet in the Nambu cartridge (most recipes call bullets ranging from 100-107 grains).

Bit of trivia, since several folks quote Midway data for the Nambu catridge.

Larry Potterfield started out at a little shop and one of his first products of his

own was reloaded ammo for the Nambu which was pretty much impossible to

find in the mid 80s - of course, that hasn't changed very much.

Bill

If it was easy, anybody could do it.

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

The first step is lubricating the brass with Imperial sizing wax and then running them through the full length Redding 8mm Nambu sizing die. I used my Forster Co-Ax single stage press for the task and even with its compound leverage it took quite a bit of oomph. Step 2 was to trim the necks back to the correct length as reducing the diameter from .355" to .320" made that excess brass squeeze the neck longer. Chamfer the necks inside and out of any burrs. Normally that should do it. But my resize die would leave a small ridge left unsized just above the extractor groove causing each cartridge to not fully chamber in my barrel. Or else it's the Co-Ax's universal chuck jaws causing the brass to sit too low. So I needed to chuck each cartridge in my mini-lathe and mill it down by .001". They all chambered perfectly in my barrel. There is no loss of integrity by removing this small amount of brass at the strongest part of that 357 SIG case since it's SAAMI max average pressure is 40K psi.

Thanks. IIRC there is some sort of extension for .40 S&W cases to remove that sort of bulge, that might work. Or, worse comes to worse (for those of us not blessed with lathes), put a penny on top of the shell holder to force the case all the way into the die. Don't forget to remove the decap stem to tap the case out with a correct size punch if you leave decap stems in your sizing dies.

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

Resurrecting this thread yet again, I just finished resizing in my C-H FL die. Went smoothly enough. The Lee Classic Cast had plenty of leverage for the task. Started out with Imperial Sizing Wax (this stuff lasts so long that my current tin is pre-Redding). Soon tired of that and decided I'd try some of the spray on wax (don't recollect if the spray bottle is still the original stuff from Midway, or refill from the Hornady One shot refill bottle). Worked like a charm, no noticeably greater effort than the Imperial.

Then I ran into a problem. My Lyman 8mm case trimmer pilot was too large for the reformed case. I've ordered .32 and .31 pilots to see if they work better. Tried the expander from the C-H die set, but it really belled the case. And then I'll get to see if the little "belt" is too much for my chamber, or if I have to run them all through the sizer again to eliminate that bulge with the penny trick. By the time I get there, I'll have so much effort invested in these cases I think I'll use a quarter.

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

Since 1904, the Japanese army ordnance cartridge that has followed in the two wars.

At the end of the last war the ammunition dumps were blown up and they were only small guns Nambu spoils of war. The cartridges were often derived from the shells of .30 Luger.

The 8mm. Nambu has lower power than the .32 acp for its charging can be used in a bullet alloy melted and drawn by .32

Weapons are of little value and refills shall be carried out with attention to the pressure, they remain modest.

Damn me, some time ago I threw away 500 shells of 30 luger that you could fit! These are loaded from an Italian site...

Weapons are like money ... no one ever has enough

Thank you Saltner, that is useful information, though I don't know whether the loads are a bit light - or just smart. The 8mm Nambu is usually loaded with a 103 grain bullet at about 1065 feet per second velocity, resulting in an energy calculation of 259 foot pounds. The .32 ACP (7.65 Browning), using Fiocci data of 73 grain FMJ at 1000 feet per second results in an energy of 162 foot pounds. The 8mm Nambu is close to the .380 ACP (9mm Browning Corto). both at about 200 foot pounds of energy. The .357 Sig reforms nicely. The .31 Lyman trimmer pilot worked, or at least will work with cases formed with C&H dies. Obviously pushing the cases too far into the die will really mess up the headspace, so I'm having Buckshot make me a hardened ring die to squeeze the last little bit of belt out of the cases. Pretty soon these will be good to go.

Last edited by Ed in North Texas; 01-21-2014 at 08:12 PM. Reason: Added info

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

Is a pleasure to help, however with a weapon like that you should start with low doses and increase them up when the weapon fails to make the cycle of armament.

Is useless and dangerous to travel at peak performance.

Weapons are like money ... no one ever has enough

This is my new favorite load for my Type 14 Nambu:

111.3gr roundnose sized to .320" 15BHN

3.7gr Titegroup

357SIG reformed cases

Rem 1 1/2 primer

1.242" overall length

1038 avg fps

13 SD

38 ES

Shoots to point of aim at 25 yards.

To form from readily available .40 S&W cases:

Take the decapping stem out of a 30-30 Winchester sizing die and place it in your press. Adjust it so that the ram (without shell holder) touches the die.

Place a piece of metal or thick washer across the top of the press ram instead of inserting a shell holder.

Lube the case, place it on top of the ram and push it into the 30-30 die. Lower the ram. The case will stay in the die.

Using a long punch or 5/16" bolt, drive the case out of the die.

What you are doing is reducing the size of the head and rim of the .40 S&W case. The process does not hurt the press, die or cases.

Now insert your 8mm Nambu sizing die in your press, install the correct shell holder, lube and size the cases.

This removes the primer and forms the shoulder correctly.

Cheap brass! Reprime, load and shoot. Enjoy!

3006guns,

Did you find the .40 S&W formed cases were longer than 8mm Nambu cases? I found the .357 Sig cases resulted in a case which was longer than new 8mm Nambu Midway brass (can't say how much longer because I've trimmed them all now).

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

Excellent information 3006guns. I was just thinking (not always a good idea) that buckshot might be able to make a pushthrough sizing die for case forming, where cases to be formed are lubed up and pushed through the die like sizing bullets. Any thoughts? I'm bringing this old thread back since I recently got a deal on a really nice Nambu and am wanting to start loading for it.

"Investment" is the new "Throw money at it!"

Detectives, and Cobras, and Agents!

Oh my!

Ed

CW3 USA (Ret)

VFW Life

American Legion

DAV Life

NRA Benefactor

TX State Rifle Assn Life

SAF Life

NY State Rifle and Pistol Assn Senior Member because I don't have to fight that fight in TX

JPFO Member

GOA Member

That's a neat trick with the 40S&W cases. I will have to try it. I have been too cheap to buy a bunch of brass from Huntingtons. For loading data, one place you might look is the Handloader's Digest Sixth Edition. An article in there on the subject. He was making cases from 41 Long Colt, 38 Spl, and .25/.30/.32 Remington cases. Also found an article on the internet at Guns Magazine, a while back.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |