Pm sent

Always carry, never tell.

|

|

|

I'm interested n the 180gr depending on final design.

PM sent.

I would definitely be in for a 150gr HP 4-cav brass mould. FB

From 150 to 180 is a big difference in weights for this size of boolit. 180 gr. in the 40 Short & Weak means high pressure to get anything from it. We might get a 150 gr. HP up to a 180 gr. solid if we're lucky, but no HB or HP 180 gr. You guys think about that and tell me just what you'll take... some more.

Are you saying no 180gr with the current cherry, or no 180gr at all?

But 180gr is possible with a new cherry right?

Anything is possible with a new cherry. New designs arent guaranteed to perform well though. The mold I'm thinking of is more for the 10mm but the 180hp could be used well in the 40s&w. That is not a replacement for the light-weight 150-160 grainers though.

I'd be in for the mold proposed by Battlerifle in post #6. With different HP profiles the weight could be bumped 10 or so grains up or down? Two or four cavity is good.

I'd definately be in for a 2 cavity prefered,but 4c ok, 150/160hp with the step . I have his 9mm-140gr and it great to have that step for feeding.I have a very fussy XDM.

The drawing in the following post would be perfect.

V V V V V V

Last edited by 40Super; 05-08-2012 at 01:13 PM.

sent via hammer and chisel

need oversized powder funnels , PTX's or expanders ? just ask, I make 'em for most brands plus my own styles.

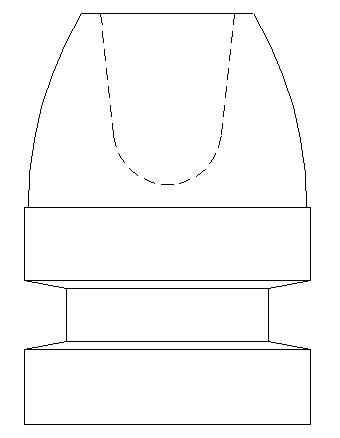

I figure something like this would weigh in at 170 grs as a solid, 160-165 as a hollow point. The bands are pretty stout and could probably be trimmed a bit for a lighter bullet:

Or a nose design like this would lighten it up and could make for some pretty exciting expansion potential:

Last edited by BattleRife; 05-08-2012 at 01:26 PM.

---------------------------------------------------------------------------

--BattleRife

Last edited by 0verkill; 05-09-2012 at 10:54 PM.

If we are up for a 200gn solid with 180gn HP, then I'm all in for a 4C brass.

Shoot from a rest at 25/50/100 yards, then post your groupings. That is the only way to compare accuracy results.

That's what I vote for if we get a new reamer made. Why make a 160gr bullet with a stepped nose if the one Miha already has a reamer to make a great 160gr mould?

Overkill: that step is only about .003"maybe .004",(never measured), there isn't enpuph to "catch" on anything and when you have a tight chamber and tight throat,by having the nose step smaller it helps quite a bit with rounds chambering. I can shoot the Miha stepped 9mm sized to .358(with .357 slugged barrels) easliy in all my 9's, but with the standard non-stepped profile nose NOE I have issues in 2 match chambered with rounds getting tight in the throat sized the same , other than using an extra short oal.

sent via hammer and chisel

need oversized powder funnels , PTX's or expanders ? just ask, I make 'em for most brands plus my own styles.

I'd be in for a 160 4 cav. with penta pins. I'd be in for any of the things discussed, but that's my first choice. This would be a significant upgrade from the Lee I'm using now and I'd really like to have HP's for both .40 and 9mm.

I'm in for this buy.....as long as it is a HP, brass mold with at least 4 cavities. Weight isn't as big a concern for me

USAF Retired

WAR EAGLE!

"A government that does not trust its law abiding citizens to keep and bear arms is its self unworthy of trust."

- James Madison

I'm after it for the 40 S&W so 200g solid is a bit heavy. A 180 solid is about as big as I believe I could go but I'm open to suggestions. Loading the 40 is the newest test on the list...

Compromise is giving up something you are unwilling to fight for! ΜOΛΩΝ ΛΑΒΕ www.concealedcarryofarkansas.com

Well... just arrrrggghhh

I was really hoping that something like Battle Rifles post #31 would quickly develop steam. That is exactly what I'm looking for in a M-P mold. I know it could be a good wait. But it's a wait I'd gladly make. The other design is just to limited for what I need. I'm not giving up hope as I believe that it would be a great and versatile design.

Thinly veiled bump to the top

Compromise is giving up something you are unwilling to fight for! ΜOΛΩΝ ΛΑΒΕ www.concealedcarryofarkansas.com

I would like a lighter weight boolit for a .400 Cor-bon, so 160 grain would float my boat.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |