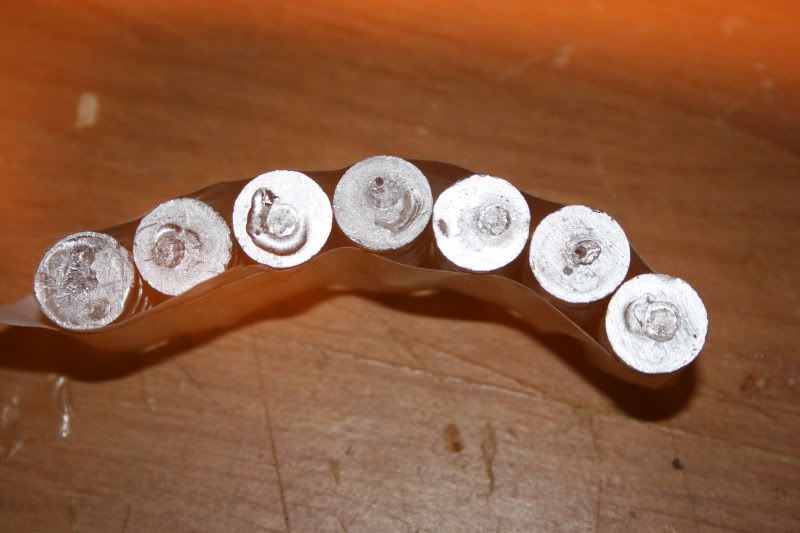

this is a photo of some the bases from my last cast job. bullets are lee 340 gr 45-70 bullets. as can be seen in the pics, there are voids and what looks like wrinkles in the base. these examples were random and can come in the middle of a perfect run. I have tried speeding up and slowing down, change pot temp in both directions.

Please help, I dont have enough hair to pull any more out.

|

|

|

Reply With Quote

Reply With Quote