30-30, 2400 & a Dacron filler

There have been several discussions regarding whether a dacron filler is “needed” with powders such as 2400, 4227, 4759, 5744 or 4198 under cast bullets in .30/.31 cal rifles. Some say the filler is not needed, some say it is and some even say it is dangerous due to pressure spikes.

My contention, based on considerable testing of loads with and without fillers, is that with light to medium weight cast bullets in the .30/.31 cal a dacron filler is beneficial by giving better consistent ignition and excellent accuracy. Whether or not the dacron filler is beneficial to you is your choice. I’ve not seen any indication of pressure spikes or other potentially dangerous problems associated with the use of a dacron filler during this testing or during the pressure testing of many test loads in different cartridges. I hadn’t used 2400 in CF rifle loads for quite a while so with the acquisition of a jug of Alliant 2400 I thought I’d work with it to develop a load for use with the GB C312-150-WFN in the 30-30 for use in my 21” Contender Barrel and in my 2 M94s.

The test bullets are cast in a Lee GB 6 cavity mould of WW + 2% tin alloy. They were inspected/selected for visual defects only, .014 aluminum GCs seated and then sized and lubed with Javelina in a .314 H die (as cast diameter). I then sized them at .311 in a Lee push through sizer.

The 30-30 cases were mixed manufacture with the flash holes reamed and were sized in a RCBS X-die. My 21” Contender test rifle 30-30 barrel is very sensitive to sizing and FTF is frequent if cases are not FL sized.

CCI 200 primers were used.

Test rifle was a Contender Carbine with a 10" twist 21" barrel. Scope was a 4X Weaver K4.

A M43 Oehler PBL was used to measure velocity and psi(M43). Start screen was 15’ from the muzzle and the M43 corrects the FPS to muzzle. Test strings were 10 shots at 100 yards.

Initial test loads were from 14 to 18 gr of 2400 in 1 gr increments without the dacron filler. The load at 16 gr proven the most accurate and quite consistent with the rifle loaded level on the bench. The average velocity was 1815 fps with a SD of 25 fps and an ES of 79 fps. The psi(M43) was 28,000 with a SD of 2,900 and an ES of 9,300. Group was 1.8”.

The 16 gr load without the dacron filler was then tested for powder position sensitivity by shooting a test string with the muzzle pointed down after loading and gently brought back to level to fire thus keeping the powder in the front of the case against the bullet. The average velocity was 1781 fps with the SD at 12 fps and the ES at 28 fps. The psi(M43) was 26,000 with the SD at 7000 and the ES at 1,900. Group size was 1.7” with the center of the group 1.75” lower.

Continuing the powder sensitivity test the muzzle was raised and then gently lowered to level for testing thus putting the powder at the back of the case against the primer. The average velocity was 1861 fps with the SD at 16 fps and the ES at 38 fps. The psi(M43) was 33,800 with the SD at 1,100 and the ES at 3,000. The group size was 1.9 and was 1.8” higher.

We see an obvious indication of powder position sensitivity. Positioning the powder forward and backward in the case both produced much more consistent ignition giving more uniform velocity and psi than with the powder just "level" in the case. While the group sized were relatively the same there was considerable vertical string giving a total group of all 3 groups of 4.82”. Thus we see a vertical stringing problem with accuracy depending on how consistently the rifle is shouldered and fired. On a target range when bench shooting this can easily be controlled and the vertical stringing alleviated. However, for me a potential 4.75 moa vertical stringing group in a field shooting environment where “positioning” of the powder prior to shooting is not practical is….well…just not practical.

Thus I proceeded to test the 2400 loads with a dacron filler. Previous experience dictated that an accuracy load with the dacron filler would probably be at a slightly lower velocity and with a lesser powder charge. I loaded 10 shot test strings of 13.5 gr to 15.5 gr of the Alliant 2400 and used a ½ - ¾ gr dacron filler.

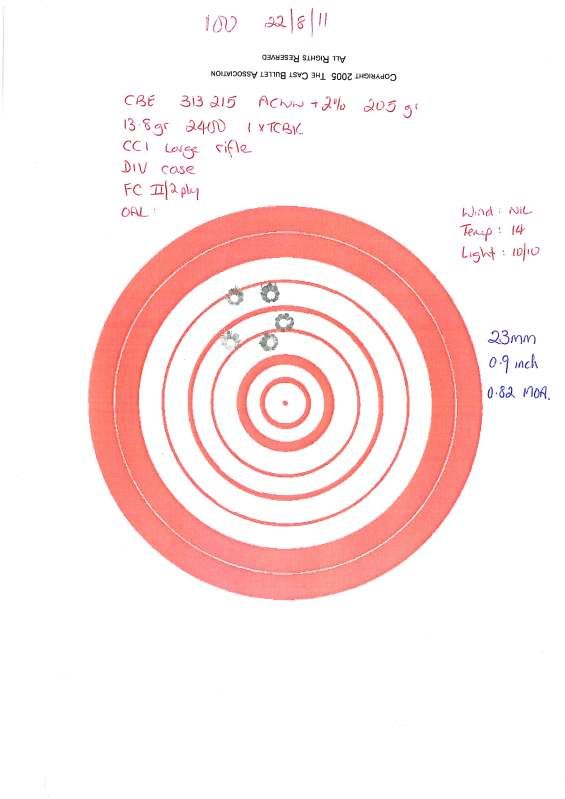

The accuracy load proved to be 14.5 gr of 2400 with the dacron filler. The same cases and primers were used in this test. The average velocity was 1722 fps with an SD at 12 fps and the ES at 42 fps. The psi(M43) was 28,700 with the SD at 1,200 and the ES at 3,400. The 10 shot group was 1.4”.

No need to test powder position sensitivity as the powder is held in position against the primer by the dacron filler regardless of the rifles held position prior to shouldering and firing. Subsequent further testing of this load to 200 yards shows excellent accuracy. This is just what I wanted for this bullet in the 30-30. This load should be quite deadly on small to medium/small varmints and game let alone deadly on rocks, sticks, dirt clods and cow pies.

Note in M43 data printout the time/pressure traces and the consistency of the “Area” and Rise” data; we can see there is absolutely no indication of “pressure spiking”. Those are pretty much “picture perfect” traces. Also note that I often trace through the bullet holes in the target onto the data sheet for a group record.

As stated previously the choice to use or not use the dacron filler is yours. For me, I use the dacron filler with this and many other loads. I do not always use the dacron filler and list my criteria in the “Filler” sticky listed above in this forum.

This test demonstrates the dacron filler works when used as directed/intended and is indeed very beneficial to increasing ignition consistency where ignition is inconsistent because of powder position sensitivity with certain powder/bullet combinations and thus increases accuracy.

I’m also convinced, based on more and more testing, that the dacron filler is also beneficial in decreasing the possibility of pressure spikes or other dangerous phenomenon when used correctly with appropriate powders. This test is indicative of the same results obtained when 4227, 4759, 5744 and 4198 are used with medium range loads , especially with the lighter to middle weight bullets for the cartridge in question. I highly recommend the dacron filler be used with those powders when lighter to middle weight cast bullets for the cartridge are used, especially in the medium velcocity range under 1900 fps.

Larry Gibson

|

|

|

Reply With Quote

Reply With Quote