This link below shows my gas check seating tool with a working demonstration :

http://www.youtube.com/watch?v=ocwMY0zNmh0

For more details on the tool go to this link :

http://castboolits.gunloads.com/showthread.php?t=130132

|

|

|

This link below shows my gas check seating tool with a working demonstration :

http://www.youtube.com/watch?v=ocwMY0zNmh0

For more details on the tool go to this link :

http://castboolits.gunloads.com/showthread.php?t=130132

Most interesting...and I wish you great success.

I drill a hole about the size of the bullet and insert the bullet point down into it. You place a GC on the base and lightly pound it home with a small plastic hmmaer--very fast and you get no nose deformation. After a few cycles the wood form fits to the bullet nose's shape...the nice thing is you can do this while watching TV. I now make my own aluminum gas checks and seating them is no longer a problem for me anymore...

Hey Ben, that's great. I take it you are using hardish lead?

I have to say I just LOVED the video of the deer rolling the dog. That rocks.

Thermal underwear style guru.

"Exclusive international distributor of Jeff Brown Hunt Club clothing."

Supplier to the rich(?) and infamous.

Cheers from New Zealand

Jeff.

I'm using ACWW's

deer rolling the dog. That rocks.

Yes JeffinNZ:

REAL funny ! ! Here is the movie again

for anyone who missed it earlier :

http://www.youtube.com/watch?v=XvqXBYE87xU

Last edited by Ben; 10-15-2011 at 07:35 AM.

Wally:

That's nice Wally, but how do you guarantee that the check is on 100% square each time ? ?

I've done that type of thing for 35 yrs. The problem is keeping 50 out of 50 bullets with a gas check that is on PERFECTLY square each and every time.

Doing this by " eye " is questionable at best. I find it near impossible.

Ben how about one to seat Plain Base Gas Checks on a 44 or 45 Colt boolit.

I have tried seating my Hornady or Freecheck III 45 Gas Checks on my 44PB boolits but they seem to come out of square to the base most of the time.

NRA Life Member

Would it not be a better unit if the body was made longer and a correctly fitting nose punch be used the seat the bullet to the check ?

With a round nose design or spire point or even using soft lead I can see mashing the nose out of shape with the hammer.

Basic design is excellent and there would be no doubt about that check being properly seated and square.

Facta non verba

Reg:

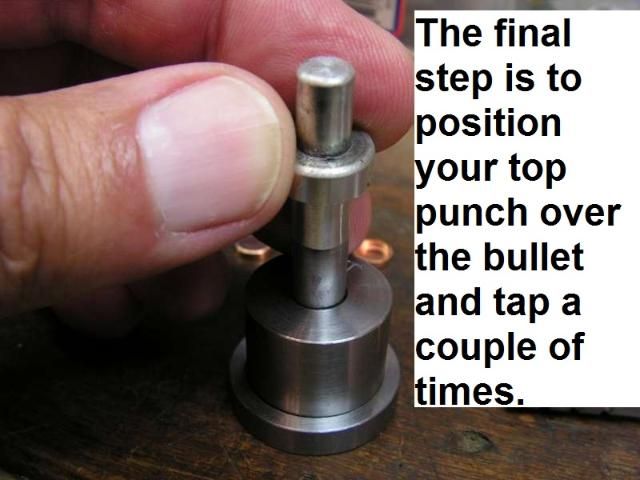

I did not explain that portion of things. But what you describe is exactly what I'm doing. I have spire pt. bullets that I use the top punch on to seat the g/c. The hammer never comes into contact with the point of the bullet. The top punch absorbs the blow and sends the bullet squarely down into the check. They don't have a mark on the nose when the seating process is completed.

Nothing is gained by using a taller die body. If all the drive bands are in the tool, that is all that matters. I have over 30 different .30 cal. gas check designs, this tool will work with any of them.

Ben

Last edited by Ben; 10-23-2011 at 09:18 AM.

Swede44mag :

I would not think it possible to use a standard g/c on a bullet that doesn't have a gas check shank.

It is possible to fit a g/c on a plain based bullet but it must be spec'd for this purpose. Pat Marlin makes these in a variety of calibers.

Ben

Last edited by Ben; 10-21-2011 at 08:50 AM.

Ben,

Very good. I can now see where if one used a typical, "fitting", top punch and say with a rawhide or plastic tipped hammer you could seat the checks and do no damage either to the nose of the bullet or the nose punch itself.

Still say, great design. Have stumbled with fitting these things myself for years. The gizmo you dreamed up should seat checks perfectly flat.

Facta non verba

Reg :

I shot my new 30-06 Tikka rifle yesterday at 100 yards, I shot bullets that had g/c's on them , installed with my new tool.

I bought the Tikka on Saturday and it was my first trip to the range to test the rifle and my loads with cast bullets.

The 1st three rounds on the target were in a " ragged hole". SAECO # 301 sized 310" , 16.0 grs. of 2400, Hornady g/c.

The tool works ! !

Ben

Very nice, now where do I get mine?

GSSF RSO

NRA RSO

DU

"People sleep peaceably in their beds at night only because rough men stand ready to do violence on their behalf."

George Orwell

These are the times that try men's souls.

Thomas Payne

PK,

Right now Buckshot is the only person who has the specs and is making them.

It is all right here, not certain if you've read this or not ?

http://castboolits.gunloads.com/showthread.php?t=130132

You're very welcome. I do not regret buying mine. I only wish I'd had this tool 40 yrs. ago.

Ben

thanks Ben I'll just wait to hear from buckshot

Wally

If it works for you, I'd stay with it.....................

I have long used the Lyman gas check seater with their luber/sizer. It works perfectly for me.

I seat all of the gas checks first, then I lube/size.

However, when it comes to pistol and revolver bullets I shoot very few gas checks. I don't need them. I use plain base bullets in them almost entirely (although I have a few moulds for gas check designs).

Dale53

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |