First off let me say hello. I have gleaned a ton of information from this site since I found it searching for bullet molds over a year ago.

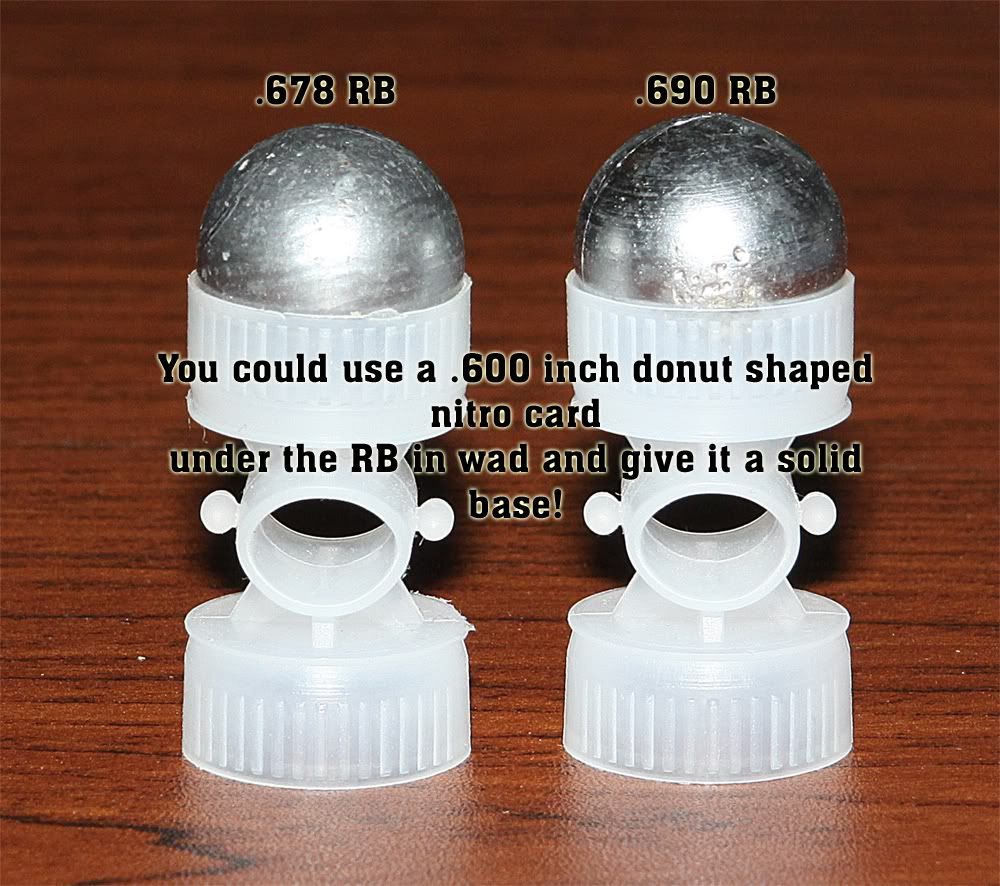

I have been reloading metallic cartridge for a few years now, started in with a shot-shell reloader about a year ago, and started casting this year. I have been working on a .69 round-ball load for a Siaga AK47 based semi auto shotgun. The bluedot load worked fine, but was a little underpowered running out at 1210 fps on a V-plug setting +1 which is approximately 8000psi using Remington hulls,waa12 wad, and 35.8G of bluedot using a #.189 bushing for a Lee Load All(maxed out!). Nothing wrong with them, but using to much powder than I like per load. The loadings I am making are coming from Lyman for there sabot slug( big pellet). My round-balls are cast from WW lead, and are coming out at 490G and are water quenched.

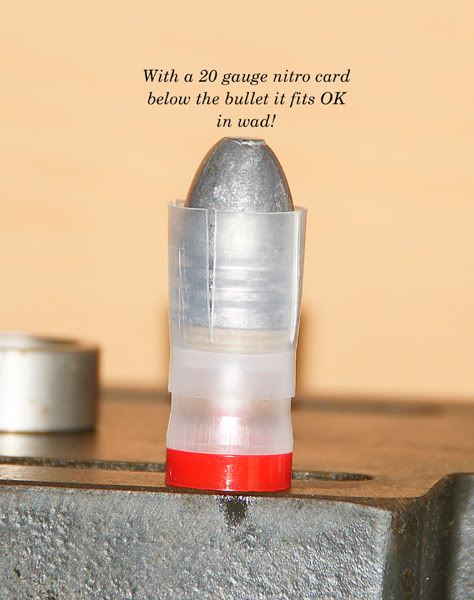

Here is my problem. Today I fired a max load( for the load all) that I worked up using Universal clays. Remington hull,209 win., WAA12,29.7G U.Clays out of a #.198 bushing. The wad cups had a hole through the shot cup to the base of the wad. The max load listed is 32.G U clays at 1416fps. and a pressure of 9,900. My setting indicate a lower pressure of around 7000 PSI, and I didn't get out the chrono today to get a fps reading. Shoots nearly flat sighted in at 50yrd line out to 100yrds. Pie plate accuracy none the less, but the wads worry me. If they are not blowing out the back, and I am on target, am I OK? No signs of overpressure on the hull base or primer pocket also.

Thanks

|

|

|

Reply With Quote

Reply With Quote