So far my paper patching for the .303 British has not gone well and continues that way.

Originally I made a mould for my .308. The mould casts a smooth boolit of 0.301" diameter which is just what the Lyman Cast Boolit Handbook says they should be.

This boolit patched to groove diameter shot quite well from my .308 so I used slightly thicker paper to patch to groove diameter for my .303 Lee Enfield. Accuracy was poor. Not horrible but not good.

I tried a variety of papers and thicknesses with little change. I then decided to knurl the boolits which raised diameter to 0.304" which is 0.001" over my bore diameter.

Accuracy improved considerably but was still not as good as I think it should be.

I decided to try some Lyman 31141 170 gr. which cast at 0.310" and patched with 0.0015" tracing paper. This resulted in a patched diameter 0f 0.316". These were then sized to 0.315". These just fit into the throat and groove diameter is 0.314".

I also patched some with cooking parchment which gave similar end result and were also sized to 0.315".

The load was a starting load of IMR4064 for "J" bullets from a reloading book (don't have the book in front of me and don't remember exactly).

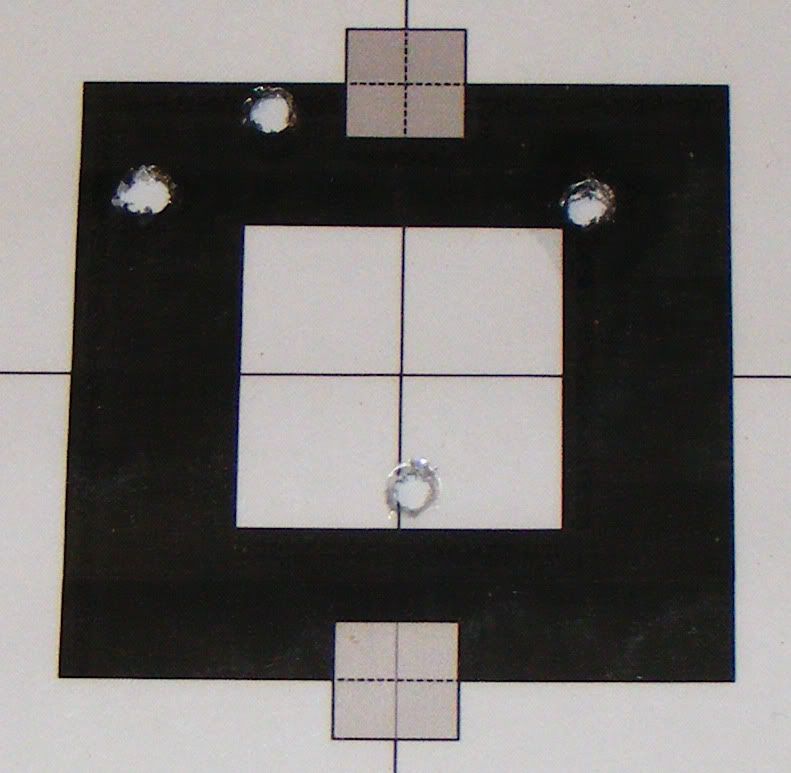

Accuracy at 50 yards was non existent! I had a few holes scattered on a 24" x 36" piece of paper! Round holes but all over and not many.

I have to think that the patch was failing though I did not check for leading. I carried on shooting GG boolits right after and accuracy was very good so if there was leading it was minor and gas checks must have scraped it out.

So, now I am wondering if I should lap or ream my smooth mould out to 0.304"/0.305" and try again that way. Accuracy had improved using the knurled boolits at 0.304".

Several people here are doing well using standard .30 cal. boolits patched up to .303 groove diameter so I thought I would try but it didn't work for me.

Boolits are ACWW.

Also, cartridge necks were annealed, case mouth bevelled, case mouths belled and a larger expander button used to suit the larger boolit giving about 0.014" inside neck (my RCBS expander button gave 0.310" neck which seemed hard on patches when seating).

Comments, criticisms, advice? All appreciated.

Longbow

|

|

|

Reply With Quote

Reply With Quote