Anyone cast with this mold and can share some of its idiosyncracies? Little itsy bitsy drive bands.... stupid thin base.... funky looking long tapered crimp goove... diameters all over the ballpark.

I've seen a lot of wierd shi... ah, stuff... over the years when casting, but nothing like this. This is the 220 grain version.

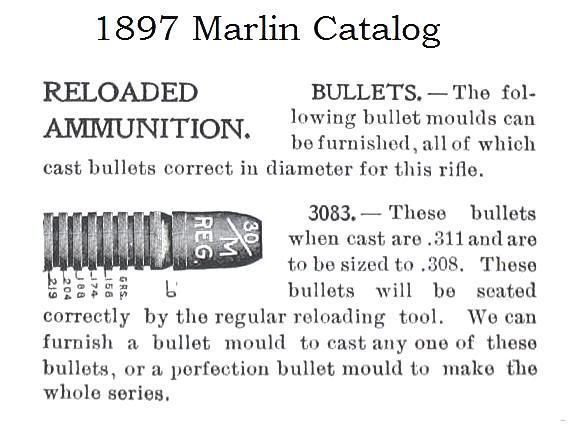

20:1 alloy at 750 degrees. Base mikes .3105. Drive bands 2 through 7 mike .306 through .309 with no rhyme or reason. Front band .311". Necassary to cast fairly warm to get fill without wrinkles as the mold needs to be cooled on almost every cycle to keep drive bangs metal from frosting and pulling back from the mold sides.

So, on to sizing... two shiny sized bands at .310 and a HUGE wide band of lube in between. Droppiing down to .309 and then to .308 still leaves a lot of lube smear... I dont get it.

Going to try some #2 alloy and then lino tomorrow to see if that changes anything.

Any thoughts, gentlemen?

|

|

|

Reply With Quote

Reply With Quote