I spent quite some time compiling and observing data to see what affects powder. This process is still developing for me and will be quite some time before I call the R&D quits because there are many ideas still brewing. Since I controlled the charcoal burn temperature and realized that density messed around a lot with my results I gained a wider range of options to customize powder for different things.

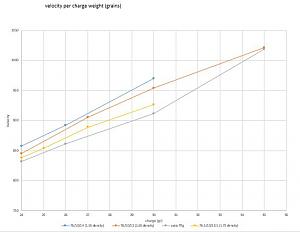

A very dense powder grains consume themselves at a slower rate than a moderate density grain of the same size. So if you are aiming for 3F but make it very dense, you might be getting 2F or even 1F.

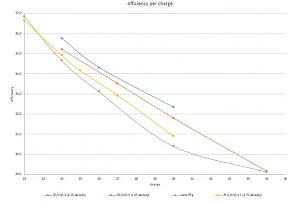

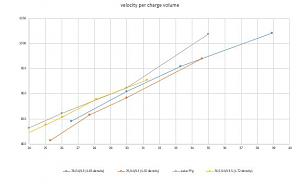

A denser powder will produce more energy per volume and therefore more power at max capacity but will be less efficient and some less dense powders can beat it in short barrels.

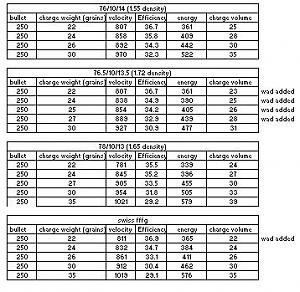

I put the results below for your viewing these results were all with a 7.5 inch SAA and all with the same 250 grain bullet from Accurate molds.

I noticed that I needed to add a wad for added compression on that 76.5 /13.5/10 powder, or the graph would be seriously weird. The swiss needed a wad because there would be airspace at those lower volumes. I have another batch milling now and will aim for 1.6, this batch was made with a charcoal cooked at 540 deg. Lighter in color and smelled very sweet like. This powder was made with willow that was like Styrofoam before cooking and very white.

Compression sure plays an important role in all this but my focus is on the "input" vs "output" or the amount of powder invested to produce a given amount of energy output. I think that the more efficient the better especially since i'm aiming for a max of 850 feet per second in this platform.

Reply With Quote

Reply With Quote