I haven't read the beginning of this thread, for several years. Went back and started reading it over. Man, how things have evolved, in 11 years!

|

|

|

I haven't read the beginning of this thread, for several years. Went back and started reading it over. Man, how things have evolved, in 11 years!

Grinding a couple batches I pucked, about 1.3 kg / almost 3 pounds. The puck breaker - an array of brass screws top and bottom - distorted and failed. The pucks are not as hard as the last lot, which had slightly more water and were pressed in shorter columns. And hand-cranking the ceramic coffee grinder is too slow when the chunks hang up. The glass jar held in my belly feels like a potential grenade whose frags must be found by probing. I have to build a better grinder!

So this batch milled for 3 hours before it turned into a hard clump on the bottom of the jar. How do you know if its enough? is there a test you guys found?

Last edited by almar; 08-21-2021 at 01:23 PM.

I tried compressing the powder dry and the humidity here is all time high levels even for GA, so it made a puck compressing at 11-11.5 tons for an hour over a 3 inch die cycling every 15 minutes or so. The results are that even with high humidity the pucks still need a bit of water, like 2 sprays for a 1 lbs batch. When I did that the pucks went from a 1.6 g/cc to 1.84 and they literally feel like plastic coasters. There must be something water does that helps the movement of the grains towards a greater compression. I never achieved such density before even with much more water so double bucks method works great as well. I wish I had a 20ton press though or 40 ton.

i'm pretty stunned here. This new batch of plum has more kno3, i wrote down the proportions for my previous batch in my one of my previous posts. This batch has these proportions:

KNO3 0.7518

charcoal 0.1409

sulpher 0.0993

l lb (454 grams)

KNO3 341

charcoal 64

sulpher 45

I loaded 25 grains by weight and this powder has 22-23 grains by weight for a 30 grain volume (this is the puck with 1.6 grams/cc i just made) under a 220 grain Johnson and dow bullet. The previous max i got with this powder was 700 or so, this powder shot 847 fps with the same weight of powder!! And the bore is clean, just a fine white residue. The max i got with 30 grains of swiss fffg under the same bullet was 871fps and an average of 842 over 2 shots. Did i really just kick swiss powders behind? more testing is required but i feel like i'm close to getting a great powder here.

Almar, you're kickin' it!

I know nothing about how ceramic media acts in the mill. I would think clumping is directly related to moisture content. However, you must have done something right, or you are very lucky. It must have mixed sufficiently before the clump. A lot of guys are using 2-6 ton presses and getting high density powder, and most say 12 tons is fully adequate. I use a 20, because it has been a part of my shop, since before I started making powder. I think you are doing amazingly well.

my clumped batches worked OK. In fact I just tested one, the velocities were fine.

I think its because I started the mill with blade-ground separate ingredients. My ball-recover mesh is ok to grate the clump to powder.

I just realised that the asymmetry I can hear in the mill that caused me to turn it off tonight was probably a clump.

yeah I think that if you load your mill up correctly with 1/2 media 1/4 powder and 1/4 empty, and the rev/min is correct, your results should be good after a few hours, some say 1.5hrs. Don't quote me on that though I'm not an expert.

On another note, my cheap chicom 12 ton press just failed structurally, I just got it. Elongated holes and tension failure as well as a little buckling. I don't think they design it with repeated max load cycling in mind. This isn't fatigue damage really but a few rare max load applications may deform the structure very slightly, but repeated applications for long periods of time will increase the plastic deformation and lead to failure. There isn't much i can do to fix this other than replace the failed parts, then if I do, how about other weak points that likely exist? I think that if you are going to use a press like this often, you better keep it at about half load and use smaller dies. Anyhow, I think I took this far enough to settle on this powder/recipe/method for rainy days. For now I have plenty of shutzen, goex, 777 and swiss to last me awhile and will use them up as well as this stuff. I took diligent notes.

Last edited by almar; 08-22-2021 at 03:36 PM.

I also had the same failure of my 12 ton Chinese press. Mine has a bolted upper structure and it was fine. I just had to replace the bottom two rails that had buckled. I had some left over cut off pieces of heavy steel 2"x4" 3/16" rectangular tubing. My block basement wall was trying to bulge inward on the upper side of the house so I braced the wall with the steel to prevent any further movement. I do not think the 12 ton pressure will distort the 3/16" steel tubing.

73 de n0ubx, Rick

NRA Benefactor Life Member/VFW Life Member

My press frame is handmade to fit the jack (20 ton truck jack) and dies

all off the farm scrap heap

base is a piece of 5 inch hot rolled channel, uprights are 4 pcs 2" x 1/2" flat

top plate is 3" channel - some heavy welding - a couple hours work

No squeakin and creakin with this rig .

Great idea to use a molten lead pot to heat the charcoal can.

Steve

NO, the batch was perfect dry powdery meal. It had run for almost 2 hrs so I didn't run it more, pulled it for pucking.

I mixed the sieved and graded powders back in the mill jar without balls, all the 4F, 3F and 1F of the previous 2 batches, and tumbled it for 2 hours to polish off the corners. 986g tumbled, gave up 24g more in fines.

I weighed the 100gn volume measure and got 91.5 gn, the exact same figure as before I tumbled it. No density gain. Darn.

That's some good info, ChrisPer. Answered a few questions. Since it gained no density, I wonder if it burns faster or slower? If it doesn't, I see no reason to really do it. I have never had the pouring problem that some have stated as a reason for polishing the grains. And, I don't think I've had a moisture absorption problem that would warrant using graphite. However, if either or both would gain consistency, I'm all ears. Thanks for the info!

Been following the thread but since I'm a screened home made BP shooter haven't had much to add recently. Just had a fun day at the local range testing out the .50 caliber CVA Mountain Rifle after getting the lock repaired by Deer Creek. I pre-measured a half dozen loads of my screened powder,100 grains by volume which weighs in at 60 grains and blew them off at 50 yds. Got on paper with all the shots with most in the second ring. Recoil was less than 65 grains of Geox 3F but it still had a good kick. I found that packing the patched ball down hard on the powder charge really made a big difference in accuracy.

My biggest problem was with the caps. I was using some older ones I had laying around that must of picked up moisture and wouldn't fire so a lot of time was spent picking out the nipple and wondering ***?. Only one out of three or four would ignite which didn't help with my aim. When I got home I found that the nipple was slightly mushroomed which didn't help ignition any and needed to be dressed with a file.

I think it's great how advanced powder making has become on this thread and all the information that is getting passed back and forth, keep up the good work everybody.

taint broke dont fix it!!!

I have shot ungraphited powder for 30 years - it runs a little slower, need to be a little more organised filling a measure, I have had zero problems with moisture absorbtion - I doubt you gain consistency (have shot sub 10 extreme spreads with ungraphited powder) .......it burns cleaner and a tad faster.

Everybody have a good, safe Labor Day Weekend! It looks like most of the country is going to have great weather, for going to the range. Get ya some of it! Buck

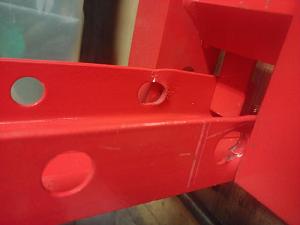

I repaired that press finally, it took some thinking to get it to work because the design limits the size and thickness but its working great. The picture shows the original angle iron used leaning against it, the unpainted angles are what I used to replace it, I doubt this will fail like before at 12 tons.

I also decided to try another brand of Kno3 from duda diesel, the one I had was from amazon. I dried everything (powder and media) before milling and sealed the ball mill well but the mosr I could mill this stuff before clumping is 4 hours. It is very fine, pressing a spoon on the powder compresses it into a glazed surface hard to describe other than like powdered sugar or corn starch. I was wondering if I could summarize all the steps I do in detail in one reply in order to get some feedback? Well see how this test batch turns out.

Last edited by almar; 09-04-2021 at 10:09 PM.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |