If you only need 2f and nothing finer.

Just take the 3f or 4f powder that you are not going to use , and Re Grind it and ball mill it.

Then wet it then screen or press it to be reprocessed closer to the grain size you will need the most of.

|

|

|

If you only need 2f and nothing finer.

Just take the 3f or 4f powder that you are not going to use , and Re Grind it and ball mill it.

Then wet it then screen or press it to be reprocessed closer to the grain size you will need the most of.

Oh I don't need that either. When I can, I shoot an 1851 Navy .36 and a Ruger Old Army.

I haven't been able to get out and shoot lately, so I'm just doing this because I read this thread.

I milled a small batch overnight. It was fine powder this morning when it came out. I lit about a half tea spoon of the meal and the whole line was instant flash with lots of smoke. I plan to screen it and run it through a rifle and see how it does there. So far I'm happy.

I have some potassium nitrate left over from about a year ago. Do I need to dry it in the over to remove any moisture? Doesn't make any difference in the milling? Does it make any difference because I'll be mixing it with water/acetone to make the putty anyway?

You shouldn't have to Dry your components unless they can be easily presses together into balls with your fingers.

If you try to mill moist material , it will clump up and roll into balls in your batch.

If you suspect your chemicals have moisture in them , then let than air dry spread out on something like a cookie sheet.

But I see no reason to Bake that components.

Can someone take a picture of the willow tree/bush they are using?

Thanks,

Steve

Maillemaker, I pulled these two pictures of Carolina Willow off Google. It's what I've been using and works well. The willows are putting out fresh leaves right now and stand out because they are a bright green. The leaf structure is most reliable way to identify willow, long and skinny staggered on the branch.

I'm confused because when I think of willow this is what I think of:

http://www.sjrstate.edu/treecampus/images/willow1.jpg

But it looks like the thing can grow as a bush instead of a tree, also.

Steve

There are plenty of different types of willow, some grow into a tree like weeping willow others just end up as a small tree or bush like the stuff I use.

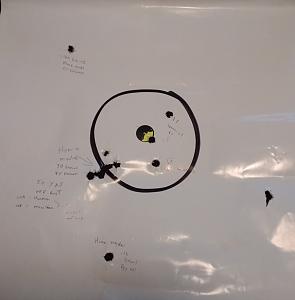

Today I tested my pressed powder vs my screened powder. Judging solely by the thump in my shoulder 80 grains of pressed was about equal to 100 grains of screened. I was using a 50 cal in-line with Lee REAL 250 boolits.

The screened was a lot cleaner burning and didn't require any cleaning between shots. I also got my best group with 100 grains of screened which was about 1.5" at 50 yards.

Considering the extra effort to make pressed I think I'll stick with screened.

I also used my flat breech plug this time. Its easier to clean than the cone shaped one and gave me a consistent squish.

My measurements were by volume. I can see why in a cartridge, where you have limited space, why it would make sense to use the more powerful pressed powder. On top of the fact that it's more durable, but for muzzle loaders it's easy to just add more powder to your load.

Since BP weight/volume is ~1:1, I just weigh my screened powder. 30 gr of roughly FFFG fills a .45C to within 1/10 inch and produces about 700 fps with a 230 gr bullet.

Growing old is mandatory, growing up is optional.

How tightly should I be compressing these pucks? Building a press here.

Also, reading up some, how safe is the corning process when putting the pucks through bigger pressure?

Urbanski (http://www.survivorlibrary.com/libra...e_iii_1967.pdf) says that there's danger of explosion from a slight sliding movement under pressure.

He also says that ball milling all three components together is incredibly dangerous, yet the pyro (and you guys) do it regularly. At least that can be mitigated by a 100 foot extension cord and some bags of dirt.

Here's a range report for what its worth using some screened powder that weighs 70% of commercial. First time out in about a year thanks to Covid so I was a little rusty. Took the CVA Hawken and the CVA Mountain Rifle out, both are .50 caliber cap locks with 1:66 twist. Remembered the powder, shooting boxes, guns, eyes and ears but forgot the targets. The R.O. was nice enough to give me a couple to get through the day and saved me a trip back home. Started with 90 grains by volume of Brazilian Pepper charcoal BP with mixed results. Found that ramming the ball down hard onto the powder and packing it with three or four good smacks really helped. Still didn't get a good grouping so moved up to 120 grains by volume which made it worse. Ended dropping down to 70 grains by volume which was the sweet spot for both rifles at 50 yds off a rest which felt like a very light load but worked. Didn't have any problems with fouling the entire day.

I tried some other loads and even shot 65 grains of Goex 3F just to see the difference but the light load of home made was the best. One thing that came to mind was that I might need a thicker patch for the heavier loads to give the rifling something to grab. All in all still a fun day at the range.

I think the general wisdom is you need to hit 3000 PSI and hold it for several minutes.How tightly should I be compressing these pucks? Building a press here.

I made up a spreadsheet to show pressure vs. puck size:

I'm using a 12 ton Harbor Freight press with a 2" puck. I crank it until it feels like it doesn't want to go anymore and let it sit for 5 minutes per press.

My densities are just slightly less than Goex.

I don't know, and honestly, it bothers me. But, everyone here seems to be pressing pucks with dampened powder without issue. But, when I'm cranking away on the jack handle with the aluminum puck full of powder about 8 inches away from my torso I am always somewhat nervous about the situation.Also, reading up some, how safe is the corning process when putting the pucks through bigger pressure?

Urbanski (http://www.survivorlibrary.com/libra...e_iii_1967.pdf) says that there's danger of explosion from a slight sliding movement under pressure.

At some point, you must mill all 3 ingredients together to make black powder. Of course pulverization of the 3 ingredients should always be done separately. But then they must be intimately mixed. We use small batches (I do 100 grams in a batch), with non-sparking media. I put my ball roller in the back yard with an extension cord.He also says that ball milling all three components together is incredibly dangerous, yet the pyro (and you guys) do it regularly. At least that can be mitigated by a 100 foot extension cord and some bags of dirt.

I wish I lived in the country as I would like to sacrifice a Harbor Freight rock tumbler drum full of media and 100 grams of green meal to see how badly it would explode if ignited.

Steve

Well, if someone wants to send me a Harbor Freight mill jar half full of lead balls, I'll take it out in the desert in the middle of nowhere and set off 100 grams of powder. I'm thinking the top will just blow off for the most part. Maybe not...

The hard part will be figuring out what to hide behind!!

Vettepilot

"Those who sacrifice freedom for security, have neither."

Benjamin Franklin. (A very wise man!)

A family member just gave me an air/hydraulic 12 ton jack. Cool!! I've always wanted one, and will be installing it in my home-made press.

Vettepilot

"Those who sacrifice freedom for security, have neither."

Benjamin Franklin. (A very wise man!)

I'm far more interested in the conditions that would cause the drum to go off rather than the effects of doing so. Less so the mill though, because that can be alleviated with a long extension cord behind some sandbags. Not so with the press. If that goes off, you have a pipe bomb in your face. I'd like to know the conditions that would set it off.

I have a friend who used to design hardened buildings and so I asked him about this issue. He pretty much laughed at me and told me to look up the gurney equations (https://en.wikipedia.org/wiki/Gurney_equations) to figure out how thick of a shield I should be hiding behind when I ran this press.

I figure it can't be that unstable, since the guys on this thread and the pyrotechnic guys do it regularly, and without incident, but still, not knowing the exact particulars of what to avoid bugs me a bit.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |