I was looking for 6.8 SPC trajectory numbers the other day and came across this page and a "various chamber designs" page linked there, quoted below.

So what sort of chamber is more bullet friendly than others? Is one of the below chambers a lead friendly chamber, or would another need to be speced for an ideal boolit 6.8SPC chamber? Would an ideal boolit chamber compromise j-word performance somehow?

Also, barrels. What's the rational for choosing between one groove option over another?

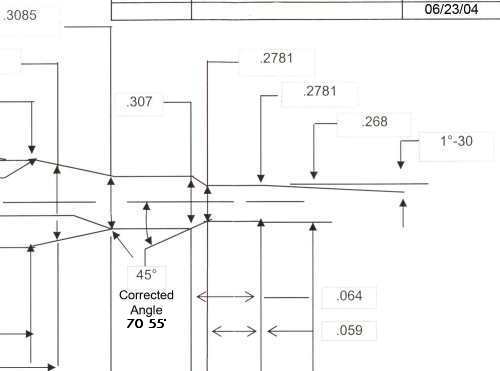

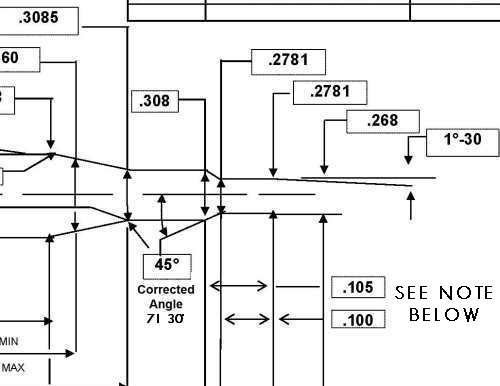

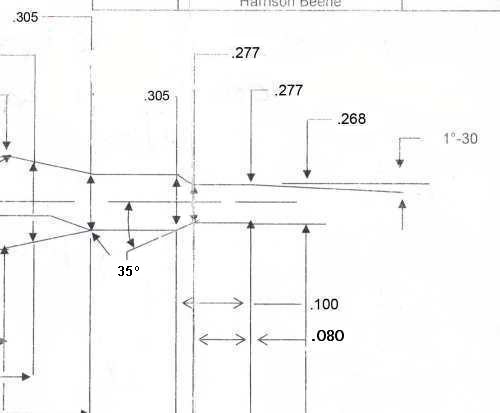

Originally Posted by www.frfrogspad.com/68chambers.htm

|

|

|

Reply With Quote

Reply With Quote