Even the hammer test does not 'expose' some issues. Seems that some gun powders will 'interact' with coating powder that is not cured correctly.

Unless you know something the coating powder mfg does not, then use the mfg curing instructions.

|

|

|

Even the hammer test does not 'expose' some issues. Seems that some gun powders will 'interact' with coating powder that is not cured correctly.

Unless you know something the coating powder mfg does not, then use the mfg curing instructions.

Tried Elvis' Ammo method once this way and it worked well. I detest standing boolits up in a tray because the process is so tedious. Took a batch of a hundred or so 9mm 125 gr. rn boolits that I had powder coated, dumped them in a couple of trays and cooked them at around 275 degrees for about 13 minutes or so. Took them out of the convection oven and shook the tray and none of the boolits stuck together or to the mesh trays from Amazon. Was using Smokes clear. Then I put the boolits back in the oven for 15 minutes at 400 degrees and water dropped them out of the oven. None of the boolits stuck together. However, having to cook boolits two times is one time too many but the results were good. Boolits shot well, leaving no streaks or any problems whatever but still just too much trouble. Big Boomer

Here's a good video from a board member:

https://m.youtube.com/watch?v=m7WLENyzNEE

The whole PC process is actually pretty simple; coat the bullet and cook it at the manufacturer's recommended time & temperature.

I will throw out a couple of points and that is start with a good quality powder that you know works. I recommend Smoke's powder to get you started. Get a good oven, meaning one that will come to temp and hold that temp without wild swings in temp. So far I haven't found any toaster oven better than the countertop Hamilton Beach convection ovens. Get a good thermometer to monitor the temp for that I recommend the Taylor Oven Guide glass thermometer off Amazon or find a vintage mercury & glass serviceman's thermometer off Ebay.

The rest of the story is in the details on how to get this done.

That's some darn good advice right there. I'd been using a really old second hand Black & Decker "Toast-R-Oven" until about a month ago when the Hamilton Beach toaster-sized convection oven went on sale. I snapped one up, and have been talking it up so hard here on the forums that I think some guys probably think I work for Hamilton Beach now.

With the previous oven, I had been getting some boolits with incomplete cures. With the new oven (and its convection feature), I can run 20 lbs of boolits at one time, and there will be zero incomplete cures. The old Black & Decker oven would swing twenty degrees to both sides of the desired temperature. The new one only swings to +/- 5 degrees. That's darn near perfect.

A very large part (all of it, really) of a powder coating's ability to perform as a jacket is based on how well it's cured. If it's not cured correctly, you're going to have problems. Curing is a matter of reaching the appropriate cure temperature, and maintaining that temperature, for the correct amount of time. If your oven isn't doing this, you will have problems.

IMO, guys that have tried PC'ing boolits and given up on it for it not working correctly, would've had a completely different experience had they cured the coating correctly, according to the powder manufacturer (or vendor) directions. And you have to be using an oven capable of completing that cure accurately.

Last edited by Phlier; 12-12-2019 at 02:14 PM.

"Things sure are a lot more like the way they are now than they used to be." --Yogi Berra

https://www.walmart.com/ip/BLACK-DEC...yABEgJtKvD_BwE

If the link works, here’s a BlacknDecker convection oven on sale at WallyWorld. I’m not a fan of Wally but this oven is pretty cheap and has TWO shelves for double capacity!

If the link don’t work, it’s a BlackNDecker convection oven for $59. On sale at Wal-mart.

For clarification, I’m pretty new to reloading and have never cast a boolit. So I can not vouch for this oven, just wanted everyone to know it was available for pretty cheap cost.

I’m lurking in the shadows learning all I can!

Taz

Just knowing enough to do it, is not enough to do it right! -Taz

Ps. I don’t know how to post a new thread yet, so if anyone wants to steal my thunder and post this for every one to see, go ahead!

Just knowing enough to do it, is not enough to do it right! -Taz

That does look like a *very* good oven for PC'ing boolits. The one I'm using right now, and also highly recommend is this one. It comes with an "air fry" basket that is perfect for putting up to 20 lbs of boolits in the oven at one time. I don't think the Black & Decker one comes with such a basket, and if you don't stand your boolits up when putting them in the oven, the basket is a needed piece of equipment. I'm sure there's one out there for the B&D oven, just a matter of finding it.

"Things sure are a lot more like the way they are now than they used to be." --Yogi Berra

When it comes to Black & Decker when I was a kid they used to make really good products, but that was 60 years ago. Now I would suggest you pass on B&D. In fact I have a new Quartz Elements Black & Decker oven I picked up for $7 at the Goodwill store because I wanted a second and backup oven. I tested it out and it wouldn't come up to 400 degrees and it has temperature downward swings as much as 40+ degrees. This oven is totally worthless for PC unless you install a PID. I can do that, but don't want to spend the time, so if any of you guys live in the Katy/Houston, Texas area and want this oven, it is free. I found a new Hamilton Beach for $20 so I have a backup oven and it works perfectly just like my old Hamilton Beach that has cooked tens of thousands of bullets since 2012.

With any of these toaster ovens you must have a good thermometer and monitor your cooking time & temperature. At 150 F. degrees the powder will flow and the bullets will look beautiful, but they are not fully cured and are not going to perform properly, but they will do a good job of coating your barrel with polymer.

You can use the smash test and it confirm the bond and the electricity of the polymer, but the smash test does not confirm the polymer is fully cured. To check for hardness take a razor knife blade and at a 90 degree angle scrape the bullet. If the coating scrapes off easily it has not reached the hardness level and is not fully cured. You can also use pencils of known hardness to check.

Last edited by Dragonheart; 12-12-2019 at 04:35 PM.

I know that you have prolly seen all the videos you want at this point in your thread but I though...'what the heck', here's another if your interested...

Here's a video that's short and to the point...

"FootStompin Powder Coating Cast FWC's"

https://www.youtube.com/watch?v=Xi2gDLxNlxQ

Don't let the fact that you'll see me tweezing the casts to the oven baking tray scare you off, that's just an 'OCD' thing with me trying to get the best and most even PC covering that I can.

You can bake them much faster if you use a wire basket and dump in a lump and bake...that's your choice.

In the video I had used AirSoft BB's & had been for years...they help to create static in the tub and help to insulate the cast from banging into each other and leaving little marks where the coating got knocked off, that's one of the reasons I like to dump the entire contents on a cookie sheet and roll the cast back and forth to get those little nicks recovered before putting them on the baking tray.

Since this old video I have been using a different type media in the tub, it's 'poly beads' that people stuff things with. They come from the crafts shops locally & are pretty cheap compared to the AirSoft BB's and one of our members 'joe leadslinger' sent me a baggie full to give a try...I like them, they seem to generate more static than my BB's did. They suggest that you use the black BB's but never could find those and I used primarily the camo colored ones.

Here you can see the little poly beads before they get covered with the PC...

Here is my first tub full of some .38S, 200 grain RN casts I used to test these poly beads with...

They covered so well the casts looked fuzzy from all the PC clinging to them. The temp was 60ºf that day with 68% humidity and not a bad combination as some of the fellas around the country have it a lot worse than I do. Joe Leadslinger lives up Oregon way where he tested on a cold and rainy day and he got the same results.

I would suggest trying the poly beads.

Here's what that first batch came out looking like...it's the ones on the right, I added a wee-bit more black and got the color on the left...I like it better.

Tapping off the excess PC gives them very clean bases without skirts and that'll be important to you when you do a profile that requires gas checks, too much PC on the cast base will make it a real 'job of work' to get them pesky gas checks on properly and square.

The 'parchment paper' will not allow the PC to stick and I get about 5 uses before it becomes brittle and needs replacement.

Some time ago I did a 'poll' here where I asked all sorts of questions to our members here about their PC process, from start to finished goods...you might find some helpful 'do's & don'ts' in this link here...

...The Devil's in the Details>>>>>PC Coatings<<<<<

http://castboolits.gunloads.com/show...lt-lt-lt-lt-lt

OK...that's about all I can think to add...be sure to post lotz of pictures of your success and if there's a problem you encounter just ask...you can see there's a lot of helpful people around this joint.

a m e r i c a n p r a v d a

Be a Patriot . . . expose their lies!

“In a time of deceit, telling the truth is a revolutionary act.” G. Orwell

Well it must have been my lucky day cause last Saturday, my wife and I went to a second hand store out by Canyon lake. Guess what they had for $15? A second hand Hamilton-Beach convection oven. Just no tray in it. So before I can try powder coating I need to find one that will fit. Anything 11.5X11.5 inches will work. Any ideas here?

ACC

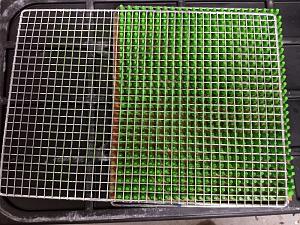

This is most likely what you need: Hamilton Beach Air Fryer Basket. At least, that's what you need if you're going to throw them all in a basket to bake. I'll see if I can find the actual tray if you want to stand them all up, and edit this post with a link to it.

That's the basket that came with my Hamilton Beach Air-Crisp Digital Toaster Oven.

I haven't measured the exact size of the basket, but if I were to estimate it, it'd be 11.5X11.5.

Edit: Here's the Crumb Tray

Here's the Baking Pan

I included the crumb tray for a reason.... if you open up the links to those pages, you'll see pictures of the actual products (of course), but notice how the baking pan is uneven; it has those rolls in it. The crumb tray is relatively flat. If I were a stand-em-up kind of guy, I think I'd rather use the crumb tray for baking PC than the actual baking pan.

Note that you will want to have a crumb tray in your oven if you don't have one already.... it helps to diffuse the infrared heat coming off of the lower heating elements, which will help prevent hot spots in your oven. Definitely something you don't want to have when you're PC'ing boolits.

Use the rack position just above the crumb tray to get maximum space below the top heating elements.

@OS OK

I also read lead slinger's post about the Poly Pellets and decided to give it a try. The results were fantastic. Not quite as good as yours, but I throw mine in a basket and bake 'em up, as it's just bulk 9mm blasting ammo.The Poly Pellet method resulted in a much more even thickness of the PC coat, and a slightly thicker coat over all. Good stuff.

Last edited by Phlier; 12-13-2019 at 02:52 PM.

"Things sure are a lot more like the way they are now than they used to be." --Yogi Berra

"Things sure are a lot more like the way they are now than they used to be." --Yogi Berra

That needs to be sung from the tree tops. There are a lot of guys out there (including me, until recently) that believe that if a PC'd boolit passes the smash test, you're good to go, when that's just simply not the case.

It was using the "scrape the boolit" test that helped me diagnose my incomplete cure problem I was having with my last oven. The boolits were passing the hammer test, but not the scrape test.

Thanks to your help (and the help of other very knowledgeable forum members), I was able to fix the issue by reducing my batch size until I finally replaced that old piece of junk oven with the new Hamilton Beach convection/toaster oven. IMO, the convection capability is really key for doing large batch sizes; there's a big difference between standing in 400F still air vs. standing in a 400F wind.Also IMO, the convection feature helps to reduce/eliminate hot/cold spots in the oven, as the air is constantly being circulated. After making the switch to a convection oven, I'd never switch back to one without... at least, not for large batch sizes.

"Things sure are a lot more like the way they are now than they used to be." --Yogi Berra

I use a thermometer and keep it at 400ºf but my timing now has gone to 20 minutes regardless of batch size.

So far I haven't ruined any from over cooking.

a m e r i c a n p r a v d a

Be a Patriot . . . expose their lies!

“In a time of deceit, telling the truth is a revolutionary act.” G. Orwell

You folks sure make some pretty bullets. Nice colors.

ACC

I have two HB Countertop Convection ovens, one slightly larger newer model and one 10+ years old. The old one has wire racks 10-1/2" x 13" and the new one racks 11" x 14". I simply cut some roof flashing and wrapped a top layer front to back over the racks, leaving me with a flat surface. I cut silicon baking mats purchased from Costco to fit the racks back in 2012 and they are still cooking. Since I have a TIG welder it was easy to make a trip to the Goodwill store and find wire racks of the approximate size that I could cut and welded to fit. I now have 4 -5 racks for each oven and can cook over 2K at a time in a HB oven. I use a SS baker's wire cooling racks to space the bullets and assist keeping the bullets upright when placing it in the oven. Photo is a 1/2 sheet pains going into my 30" oven when I want to process thousands.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |