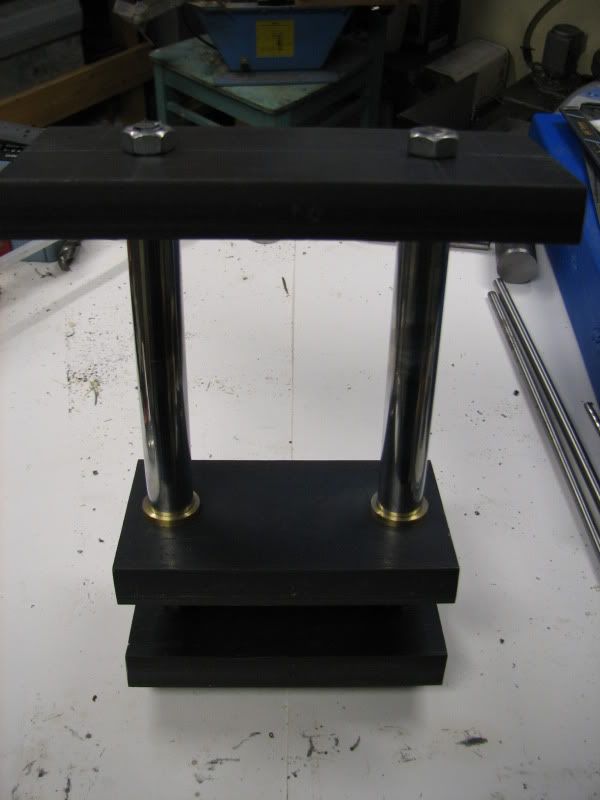

Just starting to build this, and as usual, from the materials I have on hand.

Guide rods are from VW-Golf shock absorbers, 0.8"x3.1" steel bar is from my shooting buddies scrap pile and brass bushings from local plumber. Total material cost so far at about 7.5$. Allready have rod for handlebar, need to find parts for toggle and links. This will only have about 3"+ stroke but thats all I need right now.

Sorry about the dark picture

Kaj

|

|

|

Reply With Quote

Reply With Quote

.

.