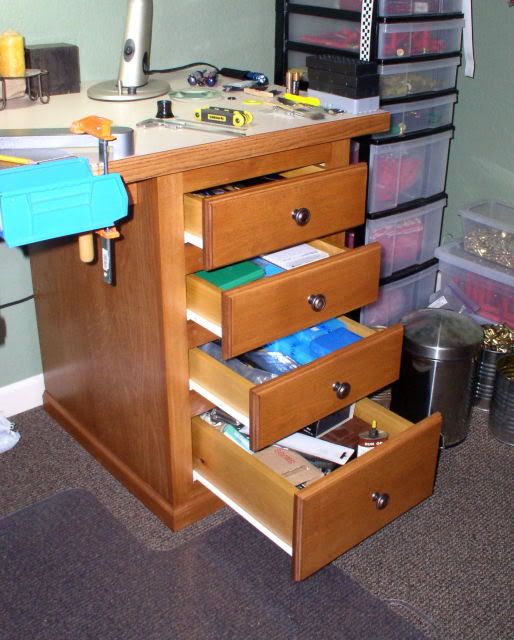

Softpoint - wow, your reloading room looks like home to me! No pictures of mine yet. The wife says I have to clean and straighten it up first, so there probably will never be any pictures.

So far it only consumes half of an unfinished basement. I still have hopes and plans for the other half.

skt

|

|

|

Reply With Quote

Reply With Quote