I have begun trying to pour two inch lube sticks for my luber. The problem I am running into is that a hollow cavity appears in the center of the stick as the lube cools. This happens regardless of if the lube is cooled at room temperature or in a freezer. Other than reaming out the hole a little and pouring in more lube after the first pour has cooled, is there another easy way to keep the center hole from appearing?

The two inch sticks I have purchased in the past do not have this hole. How do those producers keep it from happening?

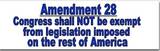

This picture may help explain my dilemma more clearly. This lube stick was cut in half after it had cooled.

|

|

|

Reply With Quote

Reply With Quote

GP100man

GP100man