Doug

Please don't get me wrong. I am not criticizing you or the work you do. From what I've seen it is first rate. What I am trying to do is determine if it will benefit any of my revolvers. If i can determine it might be then you'll, no doubt, get some work from me.

I have 15 good revolvers of S&W, Ruger, Colt and Uberti make from 32 S&WL up through 45 Colt. They all with shoot 2" or less with 12 shot groups at 25 yards from a rest [elbows resting on bench with wrists resting on sandbag]. For example, here is the 12 shot group of the first 12 shots through my 50th Anniversary Ruger FTBH 44 Magnum. Load was the RCBS 44-250-KT cast of COWW + 2& tin, sized .430 and lubed with Javelina loaded over 8.5 gr Unique. The cylinder throats pin gauge out at .431.

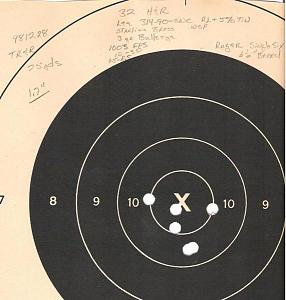

Of the 15 revolvers 3 of them have cylinder throats the same as the nominal groove diameter of the barrels; A M9S&W 357, a Ruger Vaquero (OM) 44-40 and a Colt Anaconda 44 Magnum. All three of those are the most accurate revolvers I have. However, I have one revolver, an original run Ruger SS 32 H&R that has a .312 groove diameter barrel with cylinder throats there a .312 pin gauge will almost go through but stopping about 1/16" shot. A .311 gauge will go all the way through. Thus, I consider it "undersize but this is how it shoots at 25 yards [6 shots with a TL90 gr SWC sized .312 over 3 gr Bullseye [specific load info on target];

Both of those targets are about as good as I can do these days with iron sights. Thus is my quandary, I've yet to see enough "proof" if you will, to convince me honing any of those revolver's throats would do any good? Again, no criticism intended or implied on you or your work.

Reply With Quote

Reply With Quote

DougGuy

DougGuy