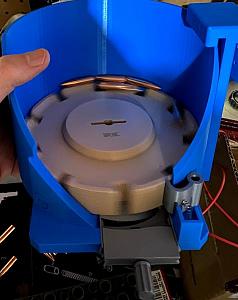

The biggest issue I had with the thingiverse one was since the bullets were so long they'd ride up on the ridge of the plate and just rotate in the back of the bowl. Your design seems to fix that issue. I'll be curious to see how well the bullet flipping part works since that was the other part that was giving me fits no matter what speed/angle I went at.

|

|

|

Reply With Quote

Reply With Quote