Hey guys, since 9mm Mak ammo may not be available forever, I want to start loading for it. Particularly for quality defensive ammo, which I can't find in any local stores. Additionally, I want to cast cheaper practice boolits. I shoot 9mm Luger occasionally, and I have been saving brass. Does anyone have experience trimming Luger brass down to Makarov specs?

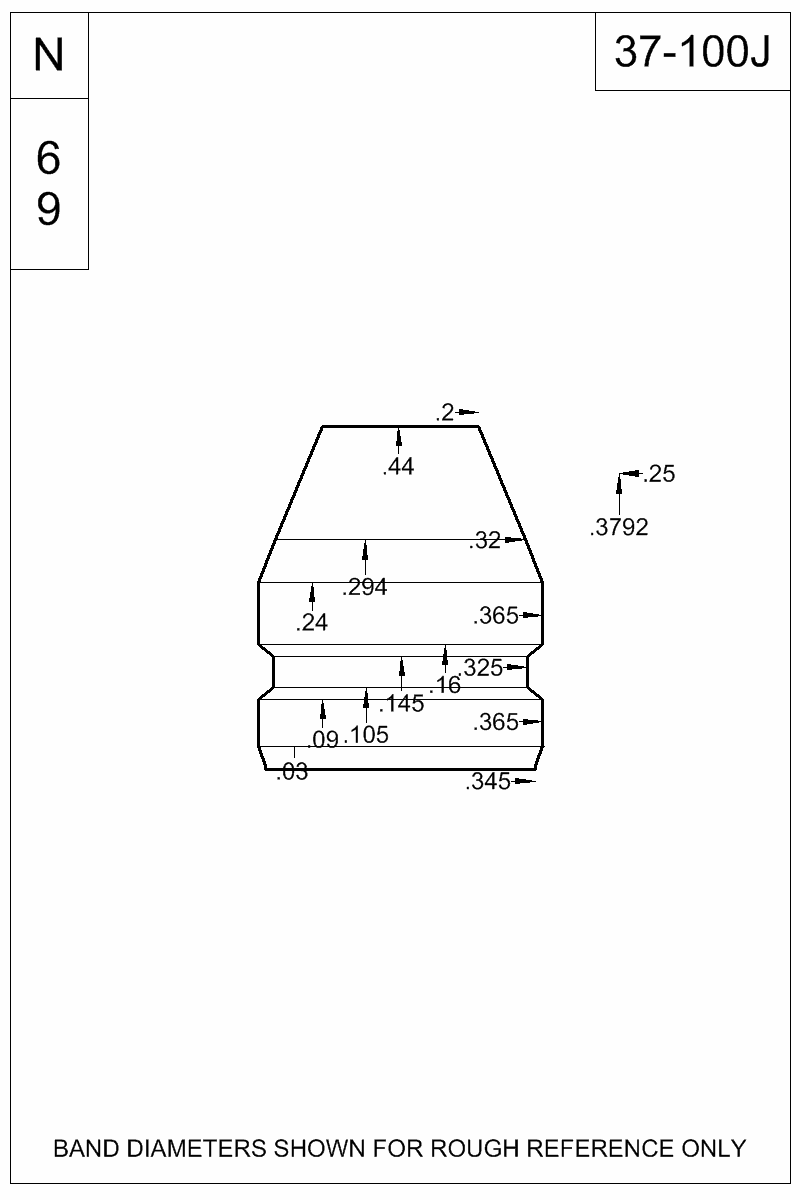

How about casting for a .360 boolit, in the 90-110 grain range? How well does this caliber respond to casting?

Thanks.

|

|

|

Reply With Quote

Reply With Quote

the 95 was just a little too light had to seat it too deep this was perfect and shot very accurate

the 95 was just a little too light had to seat it too deep this was perfect and shot very accurate