I've mentioned this a few times, finally took some photos. This is the "oven" I made for heating molds on my hot plate, works very well.

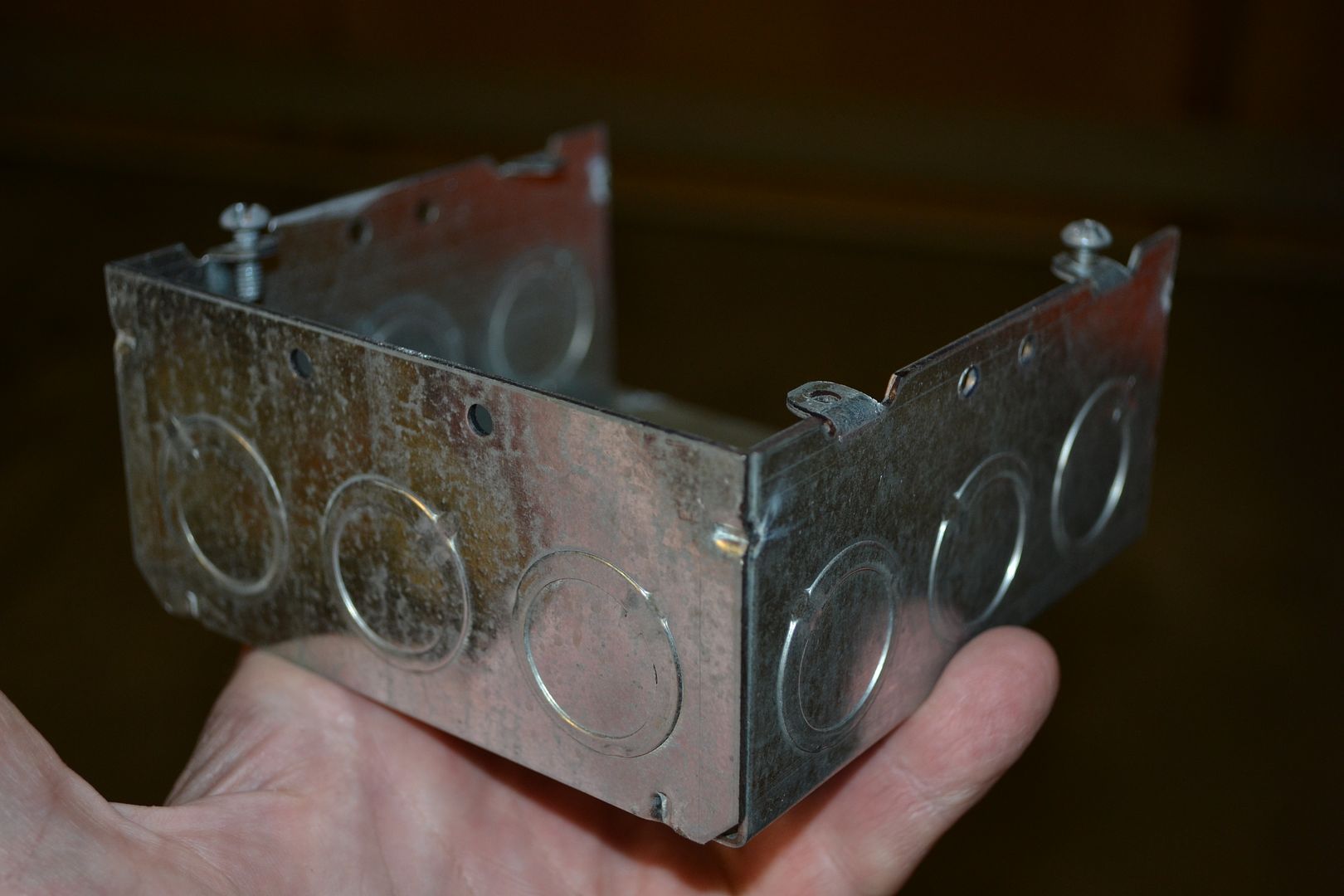

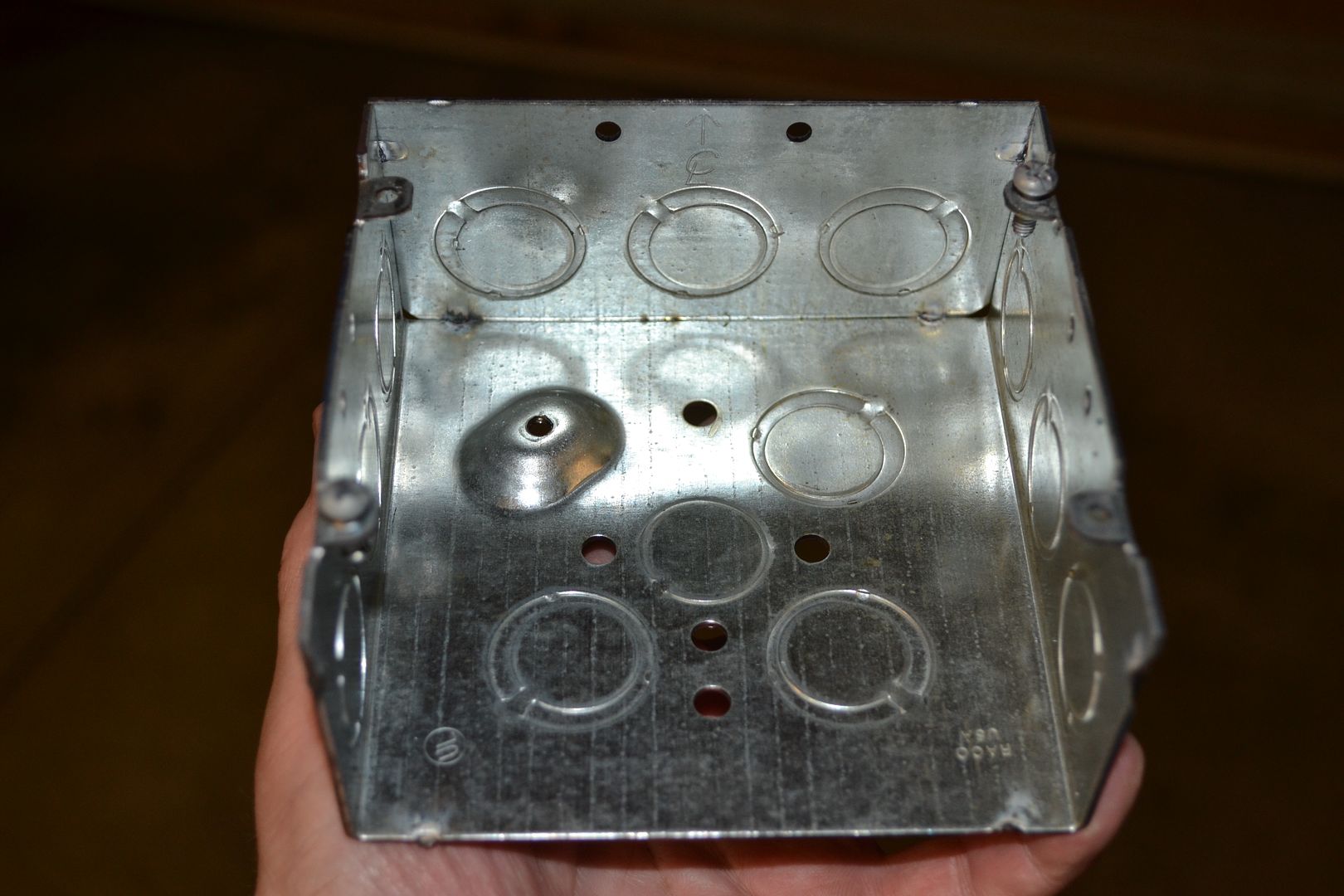

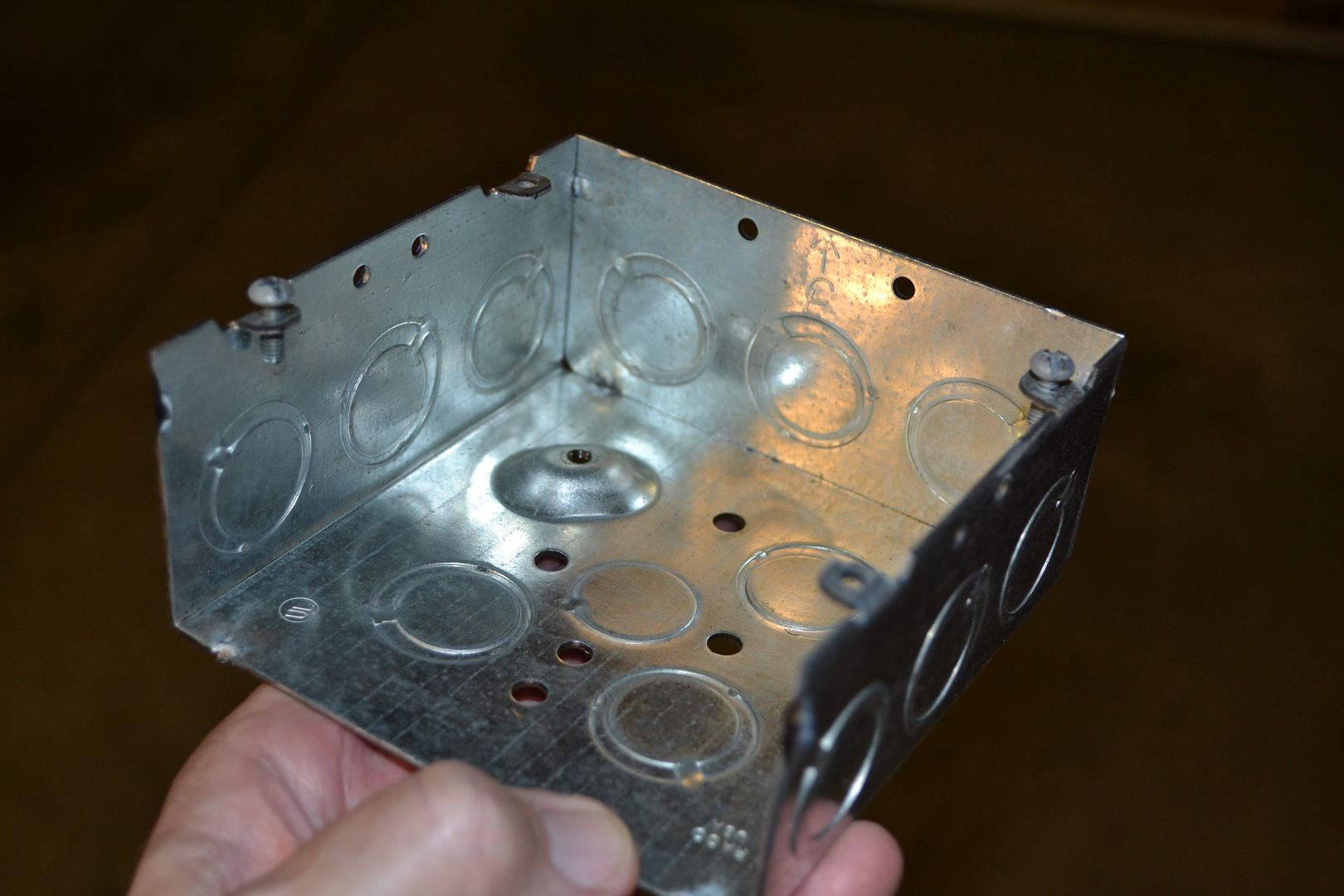

Buy a 4" junction box at Lowes or Home Depot. Get one like this that has two ends spot welded on. Make sure you get one that has both screws, seems some yahoos like to remove those things or they fall out in the store.

Remove one end, the welds are easy to defeat with pliers or a Dremel.

You need a cover plate for it too.

Assemble and put it on the hot plate with the cover plate as the bottom and git after it. It works great for heating molds and ingots, I can put two 2-cavity molds in it. I also put my dipping ladle in it to keep it hot when I'm melting more ingots or cleaning the melt in the pot.

|

|

|

Reply With Quote

Reply With Quote