jayhkr

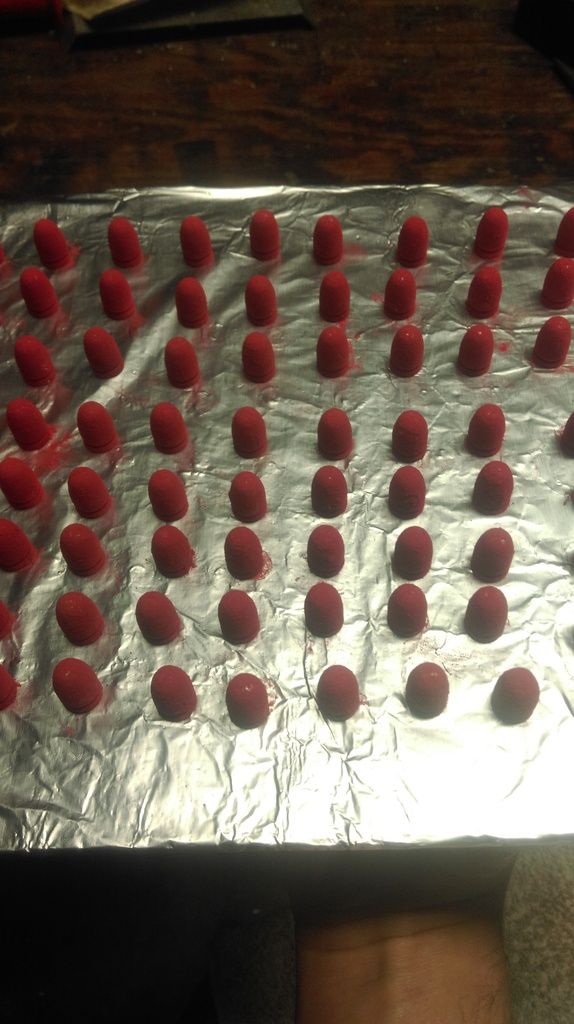

The frosty bullets won't hurt anything they will shoot just fine as has been said just turn the heat down a bit & keep going.

If you open the sprue plate too quickly (before the lead has set up) you will get lead smears on the underside of your sprue plate & the top of the mould. This is a pain so I usually wait till I see the puddle turn a dull color before I open the sprue plate.

The particles in your bullets are probably from not fluxing enough. I will put a pea sized piece of parifin on my moulton lead, stir it, & skim off the dross. This will get rid of impurities in the metal. From the looks of your last bullets you are on your way to good bullets. Keep at it it's more of an art than a science, you will soon develop a "feel" for your lead pot, lead, & mould.

let us know how it's going, but I think you are on the right track.

|

|

|

Reply With Quote

Reply With Quote