After some thought I decided to post as I go wit this one, rather than compile a report of the finished project. For one thing, I'll probably finish it sooner if I'm motivated to make daily updates. I'm pretty sure doing it this way will result in a bigger article with more detail and certainly more pictures.

So here it is, with this post I'm officially kicking off the project.

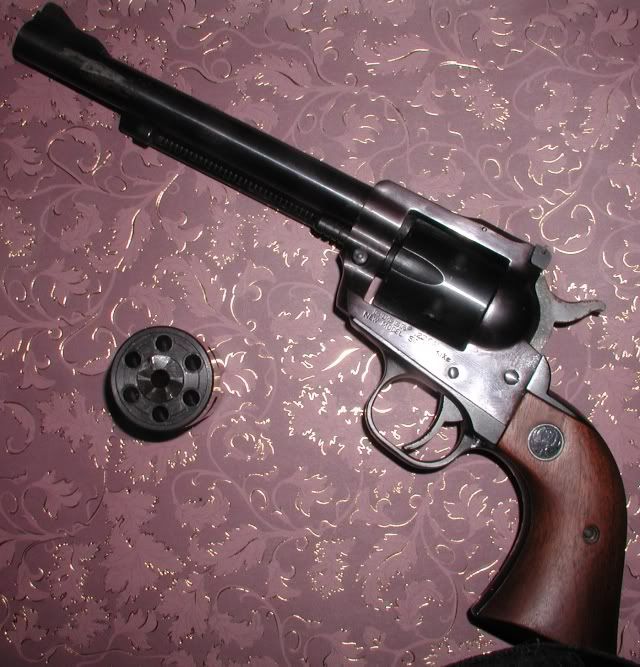

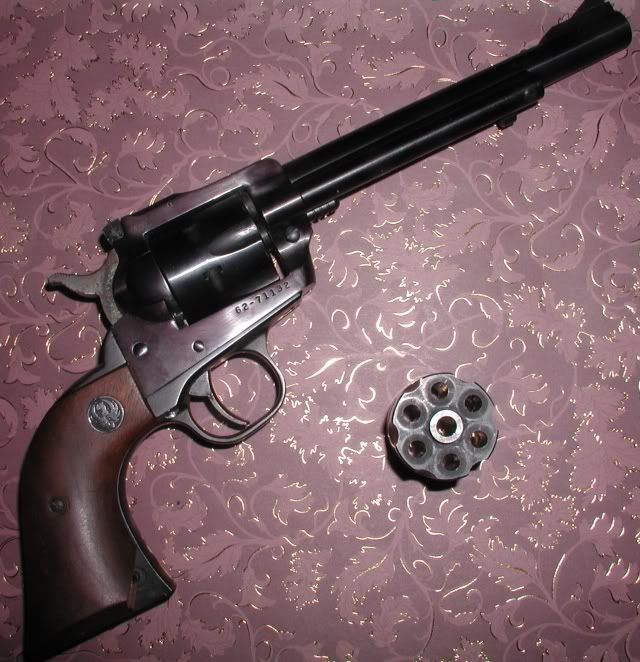

First, the gun as it is right now. I picked it up for $80, cheap because when I bought the thing, in addition to some issues with the finish, it had a mechanical problem. It turned out to be simple, just a rusted bound-up spring. I managed to chip the corner off the wooden grip all by myself just a couple days ago- please don't ask.

I started to plan a duracoating project some time back, I want to do a bolt gun I built. Then I built an AR and wanted to do that. Trouble is, they don't look so bad as they are and I'd hate to mess 'em up...so along comes an $80 .22 with a meesed-up finish, seems to me to be the perfect candidate to teach myself how to airbrush with duracoat.

Tomorrow I'm taking the pistol to my gunsmith to have him disassemble it for me, frankly revolvers scare me a little. I know I could figure it out, and I even have the book, but I don't have the proper tools and really that's not what this project is all about. So I'll drop it off, he'll probably have it for a few days. Meanwhile, tomorrow I'll go over my plan and show some pics of my airbrush set-up.

|

|

|

Reply With Quote

Reply With Quote