Did a little gun trading with a fellow gun person in Okieland and am now working with this 7" South Bend shaper getting it cleaned up, adjusted, running. It makes a pretty nice cut. I haven't run a shaper since college in 1970. This has been sitting in a welding shop for quite a while but originally came out of a school shop. It's in pretty nice shape other than multiple coats of old paint. This is one of the earlier models with manual lubrication. Pre-1963 far as I've been able to discern.

It's really amazing what these can do. They're just slow at doing it. Today I started a dovetail on a block of steel for a QC tool post to attach a Williams goose-neck parting tool to the QC setup. It's a large Williams parting tool for a 15"+ lathe. I'm going to attach the parting tool to the dovetailed block via 4 SHCS.

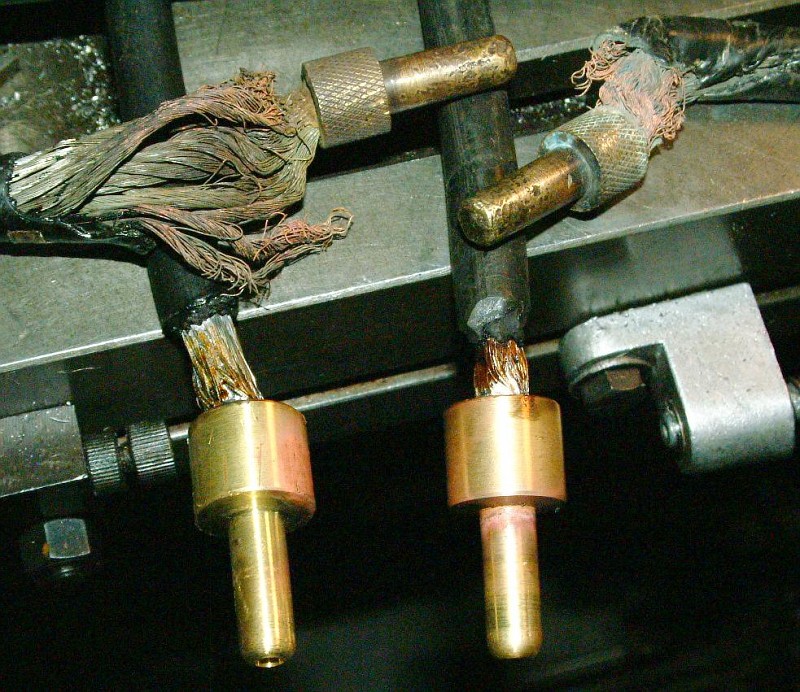

Also picked up this ancient arc welder. 180 amp A/C. It needed some maintenance in the form of new power cord, 8/3, and lathe-turned brass lugs for the welding cables. I'm not competent at arc welding as most of what I've done in the last 30 years has been oxy-acetylene welding & brazing. Lincoln arc welding company bought this company out at some distant point. It's a pretty solid welder it's just me that needs some educatin' and practice.

|

|

|

Reply With Quote

Reply With Quote