It was over 100F in the far north of Calif but it seemed like a good idea at the time.

L. to R. - Lyman 266673, Lee 452-255-RN, Lyman 323470, Lee 311-170-FN.

A bad day casting is still better than a bad day of fishing.

|

|

|

It was over 100F in the far north of Calif but it seemed like a good idea at the time.

L. to R. - Lyman 266673, Lee 452-255-RN, Lyman 323470, Lee 311-170-FN.

A bad day casting is still better than a bad day of fishing.

The hot weather didn't stop me from casting both yesterday and today as well.

Made ~ 450 200grRNFP 44's yesterday, 12.5lbs of 158grSWCTL' 357's today.

The Lee 311-170-FN is just a wee bit eccentric on the sprue. $10 single cavity ebay mold.

All things considered it doesn't shoot too bad.

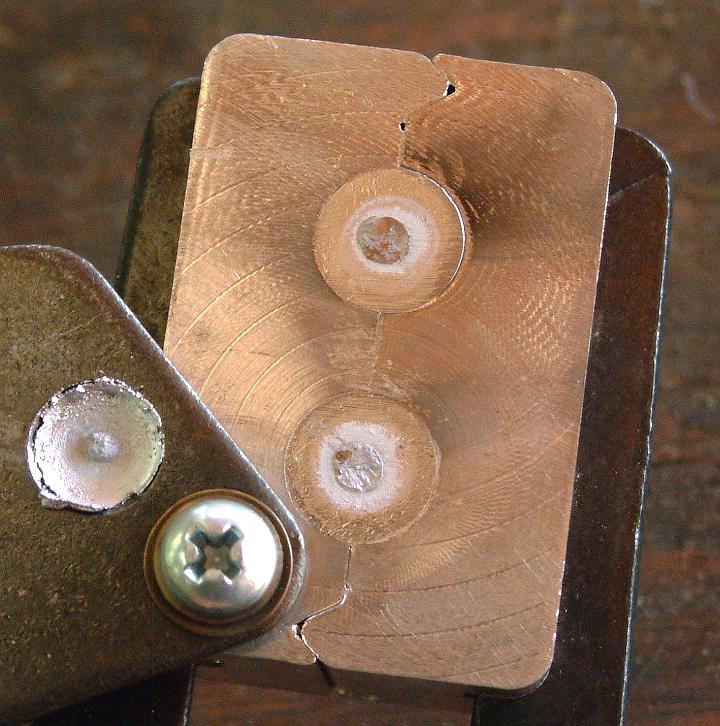

The Lyman 323470 mold is an older one with the thin sprue plate and smaller sprue holes. So I installed a brand stinkin' new Lyman spare d/c sprue plate that is thicker and has larger sprue holes that fit the Lee Pro-20 pot much better. Imagine my unpleasure at seeing the top sprue so off center.

The Lee 452-255-RN is a nice mold. Drops at .452" exactly. I've not accuracy tested this bullet yet in my S&W 2nd Model H.E. Brazilian Navy Modelo 1937 .45 AutoRim.

After at least 3 visual inspections the good boolits go in these containers to ~age~ a while.

My El Cheapo super accurate digital scale works real good. Consistancy runs about +/- 3 grains. (on the bullets not the scale!)

What doesn't pass muster gets tossed back in the pot.

Last edited by Dutchman; 08-15-2010 at 08:44 PM.

Left- Lyman 266673 150 grs .266". Right- Lyman 266469 140 grs .266" (purchased - Wayne Doudna).

After sizing & lubing I store them in ziplocks. I love ziplocks. I own stock in ziplocks. Everybody should use ziplocks daily.

My test batches get bagged up like this with pertinent data on a post-it note. I keep old post-it notes with old data. Buy ziplocks today!

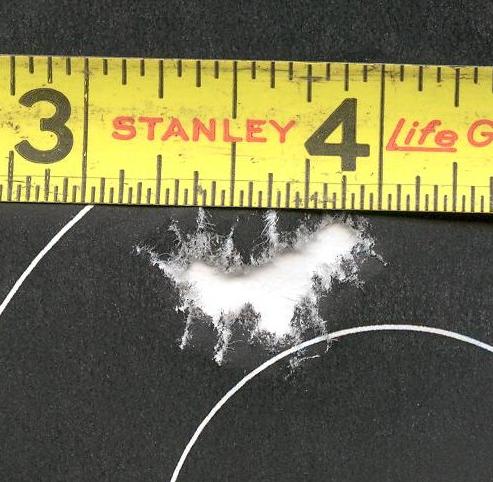

266673 over 13.2 grs 2400 @ 50 yds from m/96 Swedish Mauser with like-new bore. 5 shots.

Dutchman, Great pics.

And you are right when you

say it is never too hot to pour boolits.

Beer is proof that God loves us and wants us to be happy!

Ben Franklin

I'm a novice caster so keep that in mind. I have a couple questions. Why no towel to cushion the boolits when they drop? I tend to get dings on the bases without a cushion. Also, why so little extra lead for the sprue? I would think the voids you see in the bases would be less common and rejects would be fewer.

Until recently I've only cast with single or double cavity moulds, so I've tended to err on the side of caution when filling and dropping. I also return the sprues to the pot right away before they cool so big sprues aren't an issue for me.

Thanks for sharing the excellent photos!

Last edited by Fishman; 09-25-2011 at 10:44 AM. Reason: Spelling

"Is all this REALLY necessary?"

Fishman. Just a thought for you to think on. Every time you toss a sprue back into the pot the pot temp. changes. The heat element must work to return the pot temp. back to what it was before you tossed in solid cooler lead. Run the level down for the pot. When the level is below 1/2 to 3/4 empty then I stop and refill the pot with sprues and alloy ingots to refill the pot.Robert

The Dutchman has a harmony to his method that gets results on paper. Many casters will have different methods, The small sprue of lead is from pressure casting and allowing no overflow. You can see the imprint of the bottom pour nozzle right in the sprue. That works great for some molds and others will be not so happy. That is standard procedure with Lyman molds and methods. Lee molds are not designed for pressure casting but some Lee molds work wonderfully with the method.

You mention you are a new caster. Learn all the methods. Usually when one doesn't work, another will.

Gary

I have read a bit about pressure casting but did not recognize the signs never having tried it myself.

Not a new caster but a novice. I've been casting for almost 30 years off and on, but generally only for plinking and light duty uses. This site has opened my eyes to the possibilities thanks to its members.

"Is all this REALLY necessary?"

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |