Good morning; IF IT'S NOT TOO LATE; I'd like one, (1) two cavity 359640...round HP PINS; Thanks thebigmac

thebigmacm71@yaoo.com

|

|

|

Good morning; IF IT'S NOT TOO LATE; I'd like one, (1) two cavity 359640...round HP PINS; Thanks thebigmac

thebigmacm71@yaoo.com

NEVER, NEVER, NEVER GIVE UP YOUR GUNS..

[COLOR="#FF0000"]MANY YEARS AGO I GAVE AN OATH TO DEFEND OUR CONSTITUTION FROM

A-L-L TRAITORS, BOTH FOREIGN & DOMESTIC NOW, AT 78, I'M READY AGAIN TO ANSWER THE CALL.COLOR]

ΜOΛΩΝ ΛΑΒΕ

Go back to post #44 and send a PM to Mihec I bet he still has some, thats how I just got mine.

Bardo

Thanks Bardo, but I found out that this boolit is too light for my .35 Rem.

bigmac

NEVER, NEVER, NEVER GIVE UP YOUR GUNS..

[COLOR="#FF0000"]MANY YEARS AGO I GAVE AN OATH TO DEFEND OUR CONSTITUTION FROM

A-L-L TRAITORS, BOTH FOREIGN & DOMESTIC NOW, AT 78, I'M READY AGAIN TO ANSWER THE CALL.COLOR]

ΜOΛΩΝ ΛΑΒΕ

This mold is beautiful I must say. SUPERB craftsmanship.

I'm a noob at casting though and am having issues with base and crimp groove fillout.

Normally it's just the far cavity where the base has rounded edges.

My alloy is straight WW with 1% tin added casting at 720 degrees, and I'm casting fast enough that the sprue takes a few seconds to harden, any faster and I'd get very frosty bullets, so the mold is hot.

I guess I will try going hotter with the pot for starters. I'd like to get the shiney boolits with complete fillout, but just don't get how they do it.

Make sure you mold is hot. I use a hot plate set at about medium to preheat.

I just got one from Miha, 2 days ago. As usual, this is a pure work of art!

First casting went as expected. About 1/3 of the 20# pot was used to get it hot and "cooked in".

My first treatment of his moulds is as follows:

Hottest water you can stand barehanded with Dawn Concentrated dish soap. Disassemble mould. Put individual parts in the hot soapy solution. Using a nylon brush, scrub each mould half vigorously on the inside. Turn on hot water in other side of sink, rinse profusely as you do the other half. When done with other half, rinse it well too.

Next, I treat the pins the same way. Scrub the "fire" out of them little boogers rinse, and set aside to dry.

After everything is dry, and, I have used an airhose from the compressor to aid in this, or even a hair dryer will work, I coat the HP portion of the pins as well as their shafts with a bit of industrial spray on graphite. I don't spray it on though, I spray it in a lid and then use a Q-tip to apply. Alignment pins, bottom of sprue plate and pin/bushing too.

After it is good and dry, I begin to cast. I use almost straight wheel weights and have had problems with sharp cornered moulds with that alloy before. It has to be hot to work. Upwards of 750*F. Then, I cast as fast as I can. When bullets start to drop frosty and full, I back off a bit for speed.

To start with, with the 4 cavity moulds, I have to use a mallet to break the sprue. Once it is hot though, it is easy to break it with just your hands.

At any rate, first rate! You did it again Miha! THANKS!

Skip

Born Again 1983

USMC 1973-1979

“A reputation for a thousand years may depend upon the conduct of a single moment”

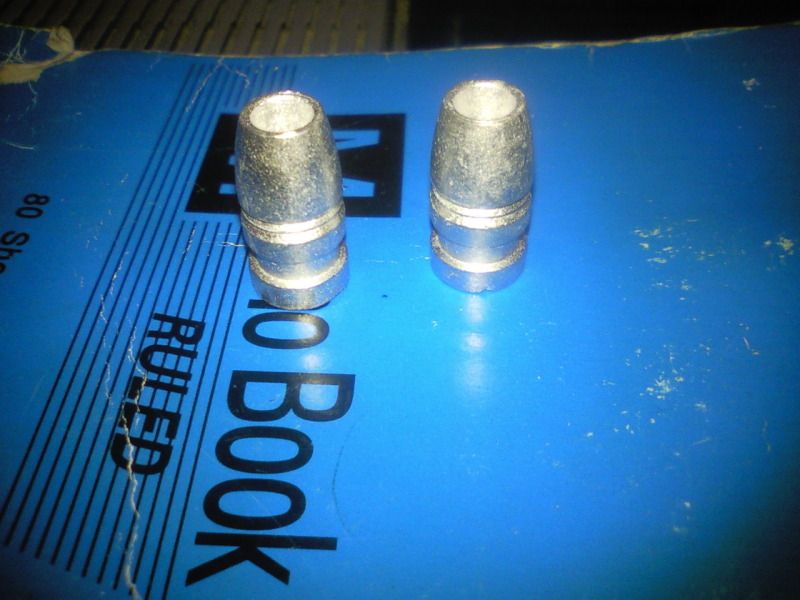

A little frosty but......nicely filled out.

Lube and size now.........

Skip

Born Again 1983

USMC 1973-1979

“A reputation for a thousand years may depend upon the conduct of a single moment”

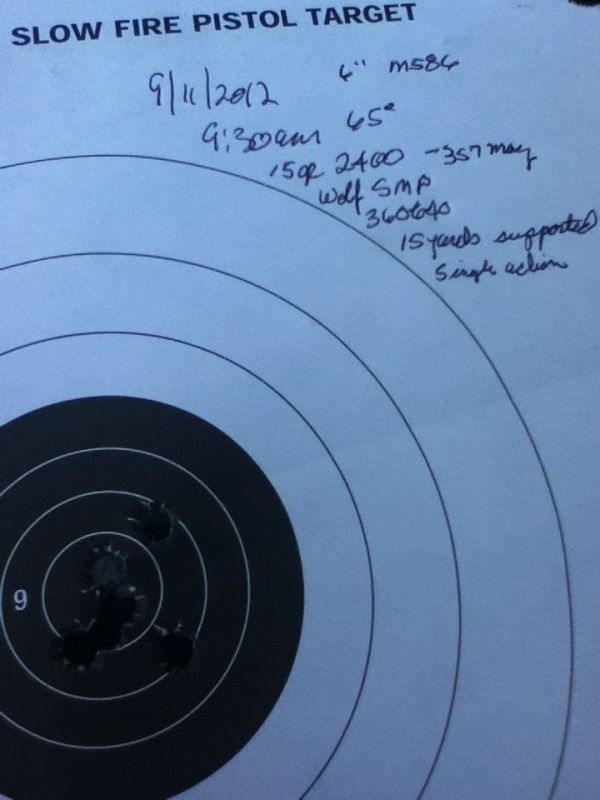

Info on target.

Didn't chronograph but they were stout. 15gr 2400 in 357Mag cases with Wolf Small Rifle Primers....

Skip

Born Again 1983

USMC 1973-1979

“A reputation for a thousand years may depend upon the conduct of a single moment”

I just finished casting my second batch with this superb mold. Casting session 1 was first attempted with the penta pins. It was a total disaster. The penta pins were so rough that I had to use a pair of pliers to get the bullets off of them. I tried painting them with lube as dirrected, I cooled them down and coated them with dropout spray, finally cooled everything down and gave up on them. I was ready to throw the whole thing in the recycle bin. Session 2 the penta pins were replaced with the round ones. The whole process was started again. I don't really understand why the round pins have such a great smooth finish on them and the pentas look like they came off of a course bench grinder wheel. The round pins were superb. The mold ran like a Corvette on the Autobahn. Perfect hollow points were pouring out of the mold like water down the Mississippi. I ran a little over 10 pounds before finally calling it a day. Three days later I lubed them up and loaded a progressive workup with 38 special cases. HP-38 powder from powderpuff to full power. This weekend they went to the range and were consumed by a Ruger Security-Six 6" and a Ruger SP-101. At 20 yards the Security Six patterned 2" and smaller groups (from a rest) tightening up to 1-1/4" at heavier loads (3.5gr of HP-38). The 2" SP-101 produced groups of about 4" with everything regardless of powder levels. It is my belief that the 2" barrel would not stabilize them very well.

Over all, this is an excellent mold with superb craftsmanship. I would buy another of this design in a 44 and never hesitate. I am going to fine dress these awful penta pins to make them smooth and try again. I will also try a batch with the plug to make some flatnose and see how they shoot.

Added: I was just looking back over the super pictures everyone here takes and looking down into the boolits cast by others with this mold and the penta pins, I do not see the awful striations inside the pentas that I got from mine. The inside of the pentas I managed to pry off the pins looked like they had been cut there with a 24 tooth sawblade. Anyone else have penta pins this rough? I'll try and get my camera working and take some decent up close pics.

Last edited by Griz44mag; 09-16-2012 at 11:01 PM.

Griz44Mag

Here in Texas, It's the Biggest, Best and Most Important (or we just won't talk about it)

My pentas with this mold were pretty rough, too... I took a fine file to them, but haven't tried to cast with them yet... I even used some fine (400 grit) paper on the round pins.... when it comes to getting boolits to drop, "smooth is good"...

Ran into a similar problem with pentas on my MP 452 200... hard to get them to release, no matter what I put on the pins for release... haven't doctored them yet, just went to round pins. I should smooth both pentas and rounds for that mold...

I have pretty good success with getting boolits to drop by coating the pins and points with graphite from a pencil. Need do it only a time or two, till the mold gets broken in.

Dale53 turned me on to using graphite with these moulds. What he does is uses the "lock lube" graphite with alcohol. I am a bit different and use the industrial spray as it has alcohol in it already. I do NOT SPRAY the pins. I spray some into the cap and use a Q-Tip for applying. I also coat the pin shafts, the pin shaft holes, the alignment pins and bushings as well as the sprue plate bushing.

I do not have to tap the mould at all to get boolits to drop at all and I have done nothing else to the pins. No emery paper, no stones, nothing, just the graphite.

It works great.....Just a suggestion.

Skip

Born Again 1983

USMC 1973-1979

“A reputation for a thousand years may depend upon the conduct of a single moment”

I have a question about this bullet design. It looks to have a large lube groove, would this be a good black powder bullet? And with the two crimp grooves, can you get a .357 OAL out of this with .38spl cases, for better feeding in .357 guns using .38spl cases?

I have a question about this bullet design. It looks to have a large lube groove, would this be a good black powder bullet? Properly done.... Yes.

And with the two crimp grooves, can you get a .357 OAL out of this with .38spl cases, for better feeding in .357 guns using .38spl cases? Close to it depending on what you do.

life.

Last edited by Three-Fifty-Seven; 05-07-2020 at 12:17 PM.

John 3: 16 For God so loved the world, that he gave his only begotten Son, that whosoever believeth in him should not perish, but have everlasting life.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |