As I mentioned, I have an original four cavity H&G mould for the #130 bullet. I have shot tens of thousands of those bullets at both target velocity and IPSC 180 power factor levels out of 1911's and S&W 625's. Properly alloyed, cast, and reloaded, those bullets just flat shoot. Just for the record, my favorite bullet for the .45 ACP is the #68 simply because it cuts a cleaner hole in the target.

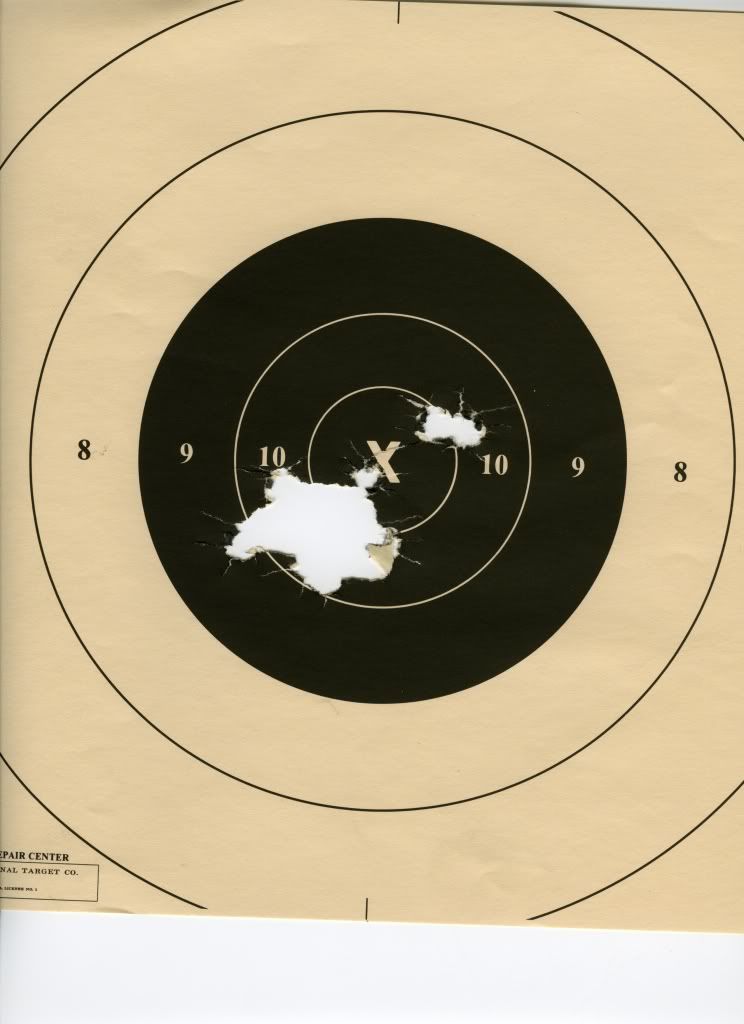

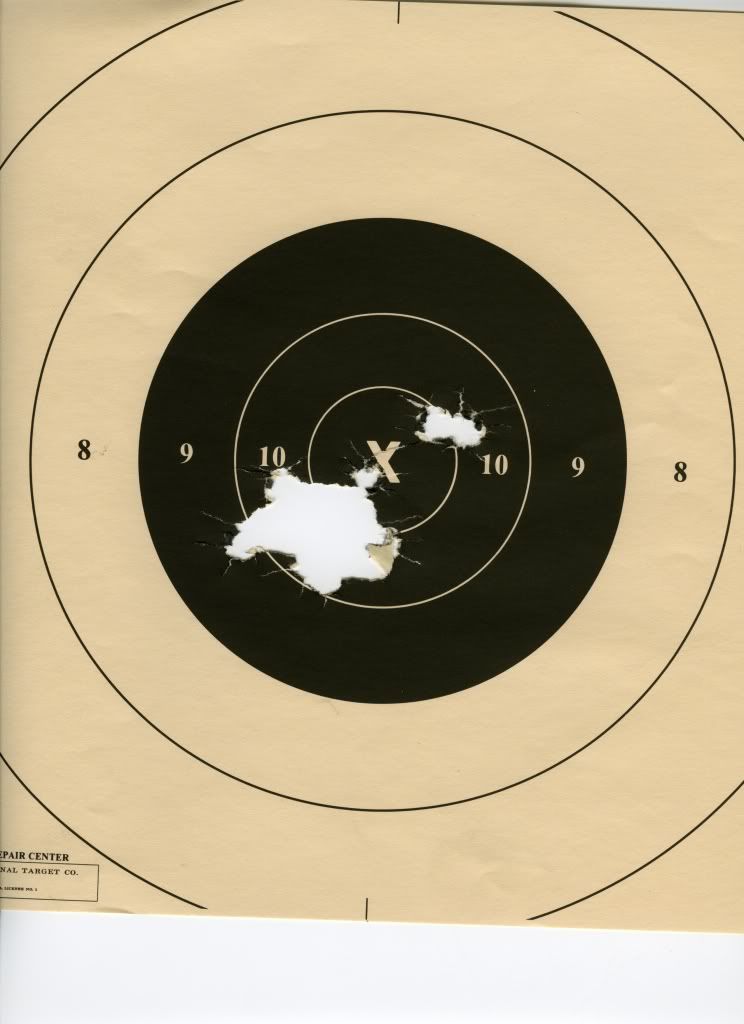

Here are results (standing at 25 yards) that explain better than I can tell you:

Hundreds of competitors at Camp Perry have used the #130 bullet at the long line (50 yards) with near perfect match scores. It's not just my fantasy, this bullet shoots. I can't give you chapter and verse at it's performance beyond 50 yards except to say that I have shot it at 100 yards on steel with excellent results. It was designed for NRA Bullseye at 25 and 50 yards and it fulfills that perfectly well.

Regarding lube - I jumped on the NRA 50/50 Alox/Beeswax lube bandwagon soon after E.H. Harrison ran the most conclusive lube tests ever performed (to the best of my knowledge). His evidence was conclusive. I even mixed several gallons of that on my own (I had a good friend in industry who could get me pure Alox 2138F in gallon sizes - normally only available in a 50 gallon drum).

I got tired of making up my own lube, used a commercial version with the same, excellent, results. Then when I discovered Lars White Label Lubes I went for Lars Carnauba Red. It seems to have all the properties of NRA 50/50 but has a higher melting point. That is a useful property when I shoot in hot weather.

So, regarding lube, I can recommend, without reservation, either NRA 50/50 (available from Lars White Label, also as well as a number of commercial sources) or his Carnauba Red. Lars prices are quite reasonable (scroll down to the bottom of the page "Lar45's LsStuff).

Since I received my MiHec #68 Clone mould, that is the bullet I shoot. However, every now and then I run a few thousand #130's because I KNOW that the performance is there also (in the 1911 platform as well as my 625s).

The above comments are not in any rate to be a diatribe against anyone else's opinion, "I'm just sayin"... If you need NRA Bullseye performance levels at distances of up to and including 50 yards, then there is NOTHING wrong with the #130 bullet.

P.S.

Doby45;

Those are excellent pictures of EXCELLENT bullets!

Dale53

Reply With Quote

Reply With Quote

. 2 examples of the lube/sized on the right and 3 examples of the unlubed bullets.

. 2 examples of the lube/sized on the right and 3 examples of the unlubed bullets.  .

.