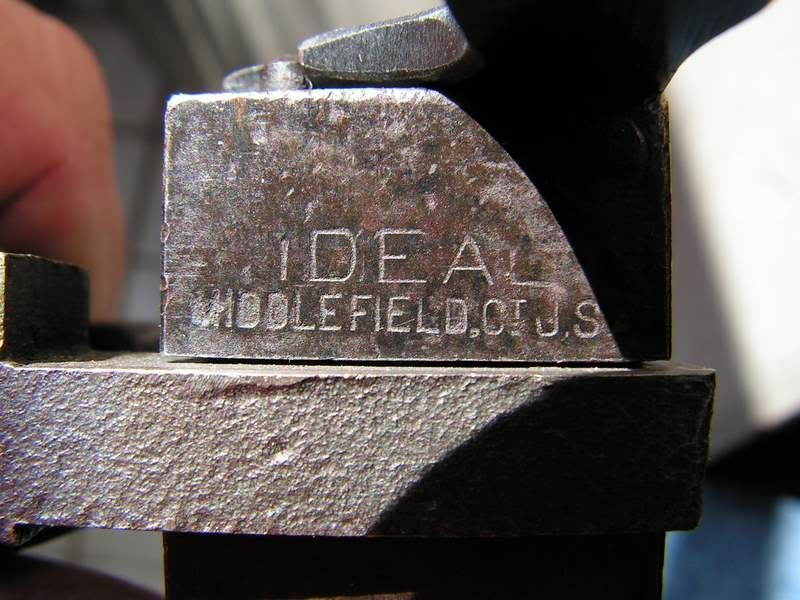

Today, I added one more mold to the mold cabinet.

Not certain that I really needed it ( does that sound familiar ? ), but I thought that there was a little history behind this one, so....I bought it.

I'm doing a search now to find out as much as I can about the history of this mold. If you have knowledge about the history of this mold, please share it with all of us.

I've found some info. about the mold here :

http://castboolits.gunloads.com/showthread.php?t=49785

I'd like to know the age of this mold ? ?

Ben

|

|

|

Reply With Quote

Reply With Quote